Application of dry quenching coke precipitator dust as heat insulation agent in iron and steel smelting

A technology for iron and steel smelting and coke CDQ, which is applied in the field of CDQ dust removal as an insulating agent in iron and steel smelting, which can solve the problems of high cost, increased cost, fine particle size, etc., and achieves reduced heat preservation cost, excellent heat preservation effect, The effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of CDQ dedusting ash is used as heat preservation agent in iron and steel smelting. In the iron and steel smelting process, it is covered with CDQ dedusting ash. The covering amount is 52kg per tank. The volume of the tank is 12m3, of which molten iron occupies 11.5m3.

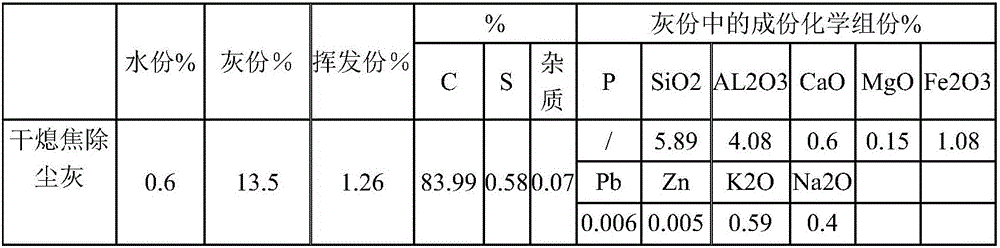

[0042] The CDQ dedusting ash, in terms of mass percentage, has a moisture content of 0.6%, an ash content of 13.5%, a volatile content of 1.26%, a carbon content of 83.99%, a sulfur content of 0.58%, and other unavoidable impurities Accounting for 0.07%. The ash content includes 5.89% silicon dioxide, 4.08% aluminum oxide, 0.6% calcium oxide, 0.15% magnesium oxide, 1.08% ferric oxide, 0.59% potassium oxide, 0.4% sodium oxide. It avoids the process of heat preservation of molten iron or adding other elements to the heat preservation agent, which reduces the preparation cost of the heat preservation agent for iron and steel smelting, and contains enough carbon so that it can effectively spontaneou...

Embodiment 2

[0044] On the basis of Example 1, the others are the same as in Example 1. A CDQ dust removal ash is used as an insulating agent in iron and steel smelting. In the iron and steel smelting process, it is covered with CDQ dust removal ash, and the coverage amount is 60kg per can. , The volume of the tank is 13m3, of which molten iron occupies 11m3.

[0045] The CDQ dedusting ash has a particle size of 20-150 mesh, accounting for 98.85% by mass.

Embodiment 3

[0047] On the basis of Example 1, the others are the same as in Example 1. A CDQ dust removal ash is used as an insulating agent in iron and steel smelting. In the iron and steel smelting process, it is covered with CDQ dust removal ash, and the coverage is 58kg per can. , The volume of the tank is 12.5m3, of which molten iron accounts for 11.3m3.

[0048] The CDQ dedusting ash has a particle size of 20-40 mesh, accounting for 14.64% by mass. The CDQ dedusting ash has a particle size of 40-60 mesh, accounting for 23.41% by mass. The CDQ dedusting ash has a particle size of 60-150 mesh, accounting for 42.3% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com