Wet spinning technology applicable to preparing livistona chinensis leaf cellulose regenerated fiber

A cellulose regeneration, wet spinning technology, applied in the cellulose solution of artificial filament, wet spinning, spinning solution preparation and other directions, can solve the problem of no report, no discovery, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation of palm leaf cellulose spinning solution: a. Dissolve 800 grams of anhydrous lithium chloride solid in dimethylacetamide solvent at a ratio of 80 grams per liter of anhydrous lithium chloride solid to make anhydrous chlorine Lithium chloride / dimethylacetamide mixed solvent 10 liters; Press the ratio of palm leaf cellulose 60 grams per liter, 600 grams of palm leaf cellulose are dissolved in 10 liters of mixed solvents that step a makes, make spinning dope 10 liters;

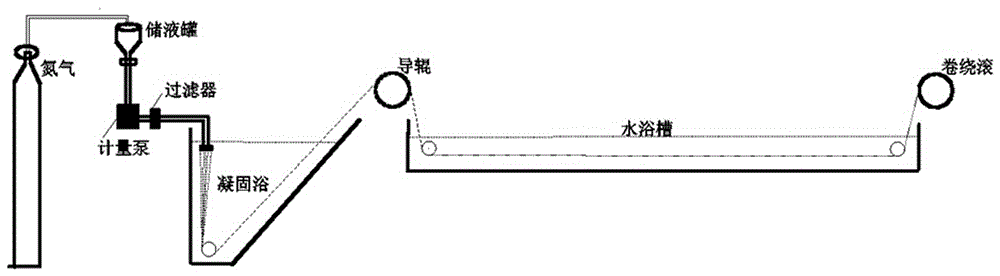

[0019] B wet spinning: pour 10 liters of spinning solution prepared in step A into the liquid storage tank of the wet spinning machine, heat the liquid storage tank of the wet spinning machine to 65 ° C, and wait for spinning in the liquid storage tank After the temperature of the silk liquid reaches equilibrium and stability: ①The spinning liquid passes through the metering pump and filter, and is sprayed out from the spinneret; ②The spinning liquid sprayed out from the spinneret is directly...

Embodiment 2

[0022] A preparation of palm leaf cellulose spinning solution: a. Dissolve 800 grams of anhydrous lithium chloride solid in dimethylacetamide solvent at a ratio of 80 grams per liter of anhydrous lithium chloride solid to make anhydrous chlorine Lithium chloride / dimethylacetamide mixed solvent 10 liters; Press the ratio of palm leaf cellulose 60 grams per liter, 600 grams of palm leaf cellulose are dissolved in 10 liters of mixed solvents that step a makes, make spinning dope 10 liters;

[0023] B wet spinning: pour 10 liters of spinning solution prepared in step A into the liquid storage tank of the wet spinning machine, heat the liquid storage tank of the wet spinning machine to 95 °C, and wait for spinning in the liquid storage tank After the temperature of the silk liquid reaches equilibrium and stability: ①The spinning liquid passes through the metering pump and filter, and is sprayed out from the spinneret; ②The spinning liquid sprayed out from the spinneret is directly ...

Embodiment 3

[0026] A preparation of palm leaf cellulose spinning solution: a. Dissolve 800 grams of anhydrous lithium chloride solid in dimethylacetamide solvent at a ratio of 80 grams per liter of anhydrous lithium chloride solid to make anhydrous chlorine Lithium chloride / dimethylacetamide mixed solvent 10 liters; Press the ratio of palm leaf cellulose 60 grams per liter, 600 grams of palm leaf cellulose are dissolved in 10 liters of mixed solvents that step a makes, make spinning dope 10 liters;

[0027] B wet spinning: pour 10 liters of spinning solution prepared in step A into the liquid storage tank of the wet spinning machine, heat the liquid storage tank of the wet spinning machine to 35 ° C, and spin in the liquid storage tank After the temperature of the silk liquid reaches equilibrium and stability: ①The spinning liquid passes through the metering pump and filter, and is sprayed out from the spinneret; ②The spinning liquid sprayed out from the spinneret is directly added to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average breaking strength | aaaaa | aaaaa |

| Average breaking strength | aaaaa | aaaaa |

| Average breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com