Gum dipping formula

A formula and dipping technology, applied in the field of industrial fabrics, can solve the problems of poor high temperature resistance, damage and failure of the adhesive layer, etc., and achieve the effect of good high temperature aging performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention discloses a dipping formula, including a first bath formula and a second bath formula, which are as follows in parts by weight:

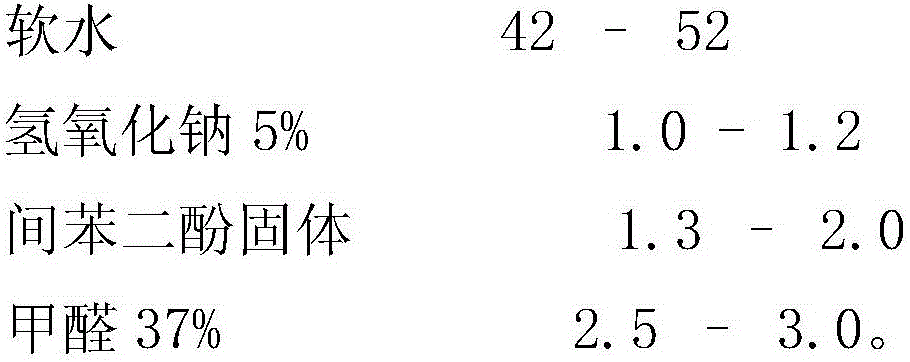

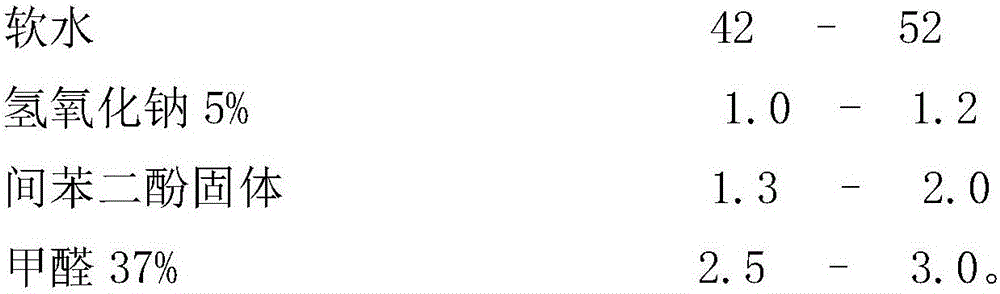

[0027] Among them, the formula of the first bath includes the following contents: caprolactam blocked isocyanate 50%: 55, RF resin liquid: 35, soft water: 800, wherein, the formula of RF resin liquid is: soft water: 42, sodium hydroxide 5%: 1.0, between Hydroquinone solid: 1.3, formaldehyde 37%: 2.5.

[0028] A second bath recipe includes the following:

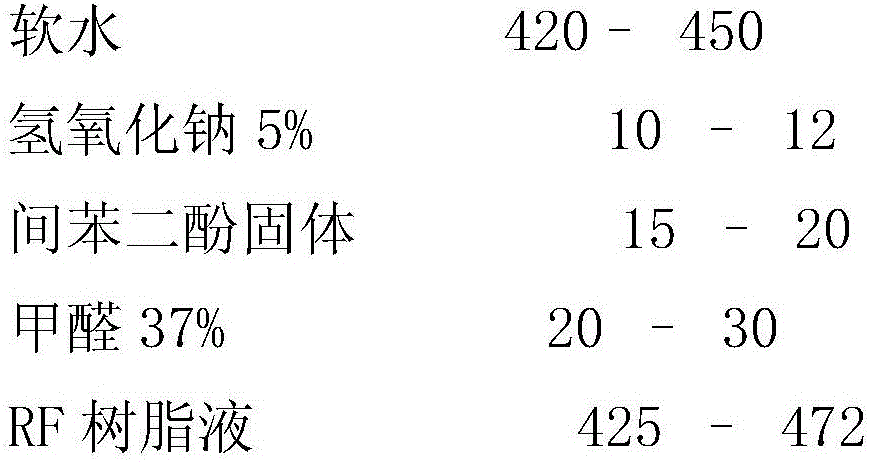

[0029] ①The formula of RF resin liquid is: soft water: 420, sodium hydroxide 5%: 10, resorcinol solid: 15, formaldehyde 37%: 20, RF resin liquid: 425,

[0030] ②The formula of RFL-dipping liquid is: RF resin liquid: 425, soft water: 90, VP latex 40%: 420.

[0031] Wherein, the solid weight ratio of RF resin liquid and latex L is between 1:4, and the total solid content of the final RFL-dipping liquid is between 14%.

Embodiment 2

[0033] The invention discloses a dipping formula, including a first bath formula and a second bath formula, which are as follows in parts by weight:

[0034] Wherein, the formula of the first bath includes the following contents: caprolactam blocked isocyanate 50%: 55, RF resin liquid: 60, soft water: 1000, wherein, the formula of RF resin liquid is: soft water: 52, sodium hydroxide 5%: 1.2, Hydroquinone solids: 2.0, formaldehyde 37%: 3.0.

[0035] A second bath recipe includes the following:

[0036] ①The formula of RF resin liquid is: soft water: 450, sodium hydroxide 5%: 12, resorcinol solid: 20, formaldehyde 37%: 30, RF resin liquid: 472,

[0037] ②The formula of RFL-dipping liquid is: RF resin liquid: 482, soft water: 100, VP latex 40%: 460.

[0038] Wherein, the solid weight ratio of RF resin liquid and latex L is between 1:6, and the total solid content of the final RFL-dipping liquid is between 25%.

Embodiment 3

[0040] The invention discloses a dipping formula, including a first bath formula and a second bath formula, which are as follows in parts by weight:

[0041] Among them, the formula of the first bath includes the following contents: caprolactam blocked isocyanate 50%: 55, RF resin liquid: 48, soft water: 900, wherein, the formula of RF resin liquid is: soft water: 48, sodium hydroxide 5%: 1.1, Hydroquinone solid: 1.7, formaldehyde 37%: 2.7.

[0042] A second bath recipe includes the following:

[0043] ①The formula of RF resin liquid is: soft water: 435, sodium hydroxide 5%: 11, resorcinol solid: 17, formaldehyde 37%: 25, RF resin liquid: 448,

[0044] ②The formula of RFL-dipping liquid is: RF resin liquid: 448, soft water: 95, VP latex 40%: 440.

[0045] Wherein, the solid weight ratio of RF resin liquid and latex L is between 1:5, and the total solid content of the final RFL-dipping liquid is between 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap