Floating type small pumping station

A floating pumping station technology, which is applied to pumping stations, motor vehicles, ships, etc., can solve the problems of long construction period, unstable operating conditions, and inconvenient maintenance of pumping stations, and achieve low requirements for water-stop materials and structural Simple, waterproof structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

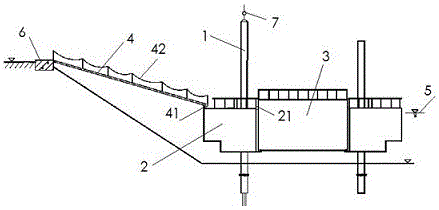

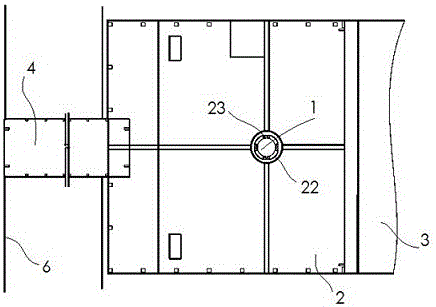

[0030] Floating small pump station, the composition of the pump station includes pile shaft 1, buoy 2, pump room 3 and traffic bridge 4; pile shaft 1 is vertically fixed in a water area suitable for water intake, buoy 2 and pump room 3 are prefabricated with reinforced concrete The empty box type overall structure. The buoy 2 and the pump chamber 3 are connected by a simply supported hinge 21, which is a socket type, and its function is a rotatable connection. Half of the hinge is a plug with a bolt hole, and the other half is a plug with a bolt hole. Concave groove, after inserting the plug into the concave groove, pass the bolt through the bolt hole and tighten the nut to form a simply supported hinge. The size and quantity of simply supported hinges are determined by calculation, and two are used in this embodiment, arranged symmetrically. The buoy 2 is provided with an inner cylinder 22 as a guide hole, and the inner cylinder is slidably matched with the pile shaft 1, and...

Embodiment 2

[0034]The bottom of the buoy 2 is an empty box with a stepped structure, and its structural size is determined by the size of the required primary buoyancy and secondary buoyancy; the primary buoyancy is determined by the total weight of the buoy 2 and the pump chamber 3, according to the minimum water absorption of the pump. The depth is determined by calculation; the second-level buoyancy is determined based on the calculation of the first-level buoyancy, plus the axial force when the water pump is working. All the other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com