Zero-emission zero-pollution circular agricultural production system

A technology of circular agriculture and production system, applied in the direction of agricultural buildings, etc., can solve the problems such as the inability of the technology to be satisfied, the promotion and application of the technology is not in place, and achieve the effect of ensuring the survival rate and yield, and improving the quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

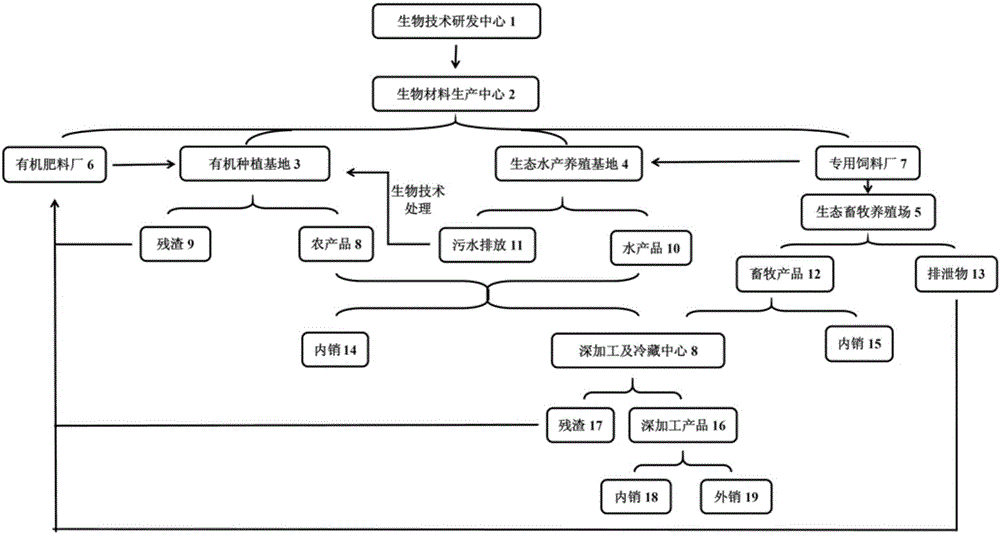

[0029] A zero-emission and zero-pollution circular agricultural production system, including a biotechnology research and development center 1, a biological material production center 2, an organic planting base 3, an ecological aquaculture base 4, an ecological livestock farm 5, an organic fertilizer factory 6, and a special feed factory 7 , deep processing and cold storage center 8. Based on modern biotechnology, Biotechnology Research and Development Center 1 develops a variety of non-toxic biomaterial products for organic planting, ecological breeding, fertilizer fermentation, antibiotic degradation, etc., which are processed and produced by Biomaterial Production Center 2 for use in organic planting bases 3. Ecological aquaculture base 4. Ecological animal husbandry farm 5. Organic fertilizer factory 6 and special feed factory 7. The agricultural products 8 produced by the organic planting base 3, the aquatic products 10 produced by the ecological aquaculture base 4, and ...

Embodiment 2

[0032] A zero-emission and zero-pollution circular agricultural production system, planned with an area of 5,000 mu, equipped with biotechnology research and development center 1 (5 mu), biological material production center 2 (25 mu), organic planting base 3 (3,500 mu), ecological aquatic products Breeding base 4 (300 mu), ecological animal husbandry farm 5 (1000 mu), organic fertilizer factory 6 (50 mu), special feed factory 7 (20 mu), deep processing and cold storage center 8 (100 mu). Among them, organic planting base 3 has a total area of 3,500 mu, which can be used to plant 500 mu of organic rice, 1,000 mu of organic fruit corn, 200 mu of organic red beans, 200 mu of organic mung beans, 200 mu of organic soybeans, and 200 mu of organic black beans. mu, 200 mu of organic soybeans, 500 mu of organic traditional Chinese medicine, and 500 mu of organic vegetables. Ecological aquaculture base 4 has a total area of 300 mu, of which 200 mu is water surface area, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com