Nondestructive measurement method for layer thickness of multilayer polymer tubular product

A technique for tubular products and measuring methods, which is applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low efficiency of measuring methods, narrow scope of application, and poor practicability, and achieve easy implementation and practicality Strong, waste-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

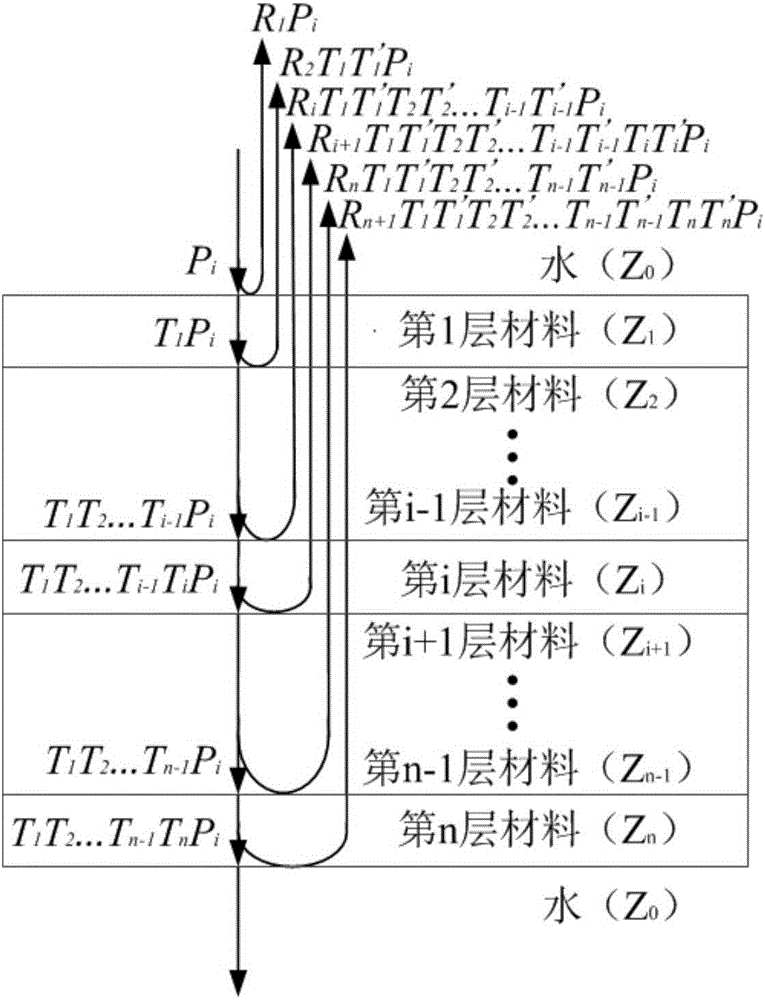

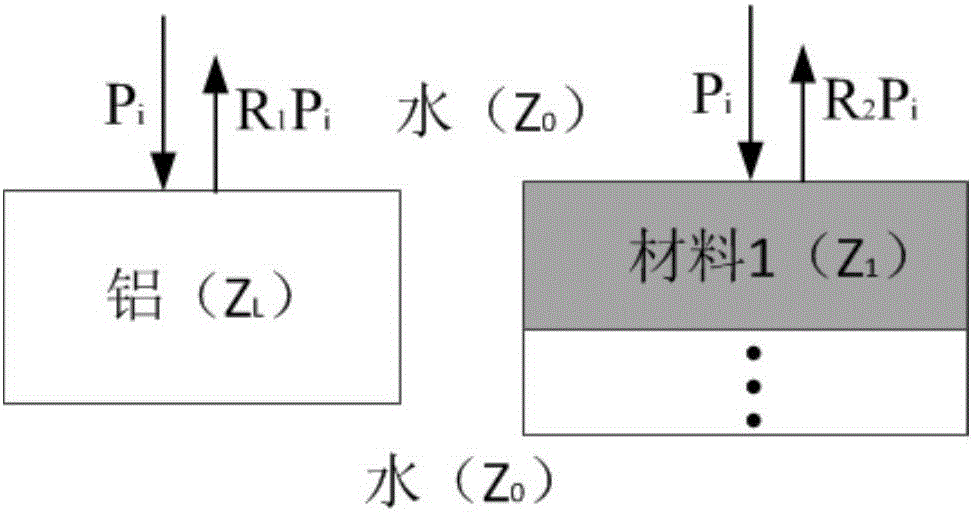

[0033] like figure 1 Shown is a schematic diagram of the propagation process of ultrasonic waves in a sample of composite structure of water and multilayer materials. Ultrasonic waves are vertically incident from the i-1th layer material to the i-th layer material, The sound pressure reflection coefficient R at the interface of i and sound pressure transmission coefficient T i Respectively as shown in formulas (1) and (2):

[0034] R i = Z i - Z i - 1 Z i + Z i - 1 - - - ( 1 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com