Wet gas liquid sampler with eccentric orifice

A technology of eccentric orifice plate and sampler, which is applied in the direction of sampling device, instrument, liquid/fluid solid measurement, etc. It can solve the problems of poor representation of liquid samples, poor representation of liquid samples, and no representativeness of flowing fluid, etc., and achieve separation efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings.

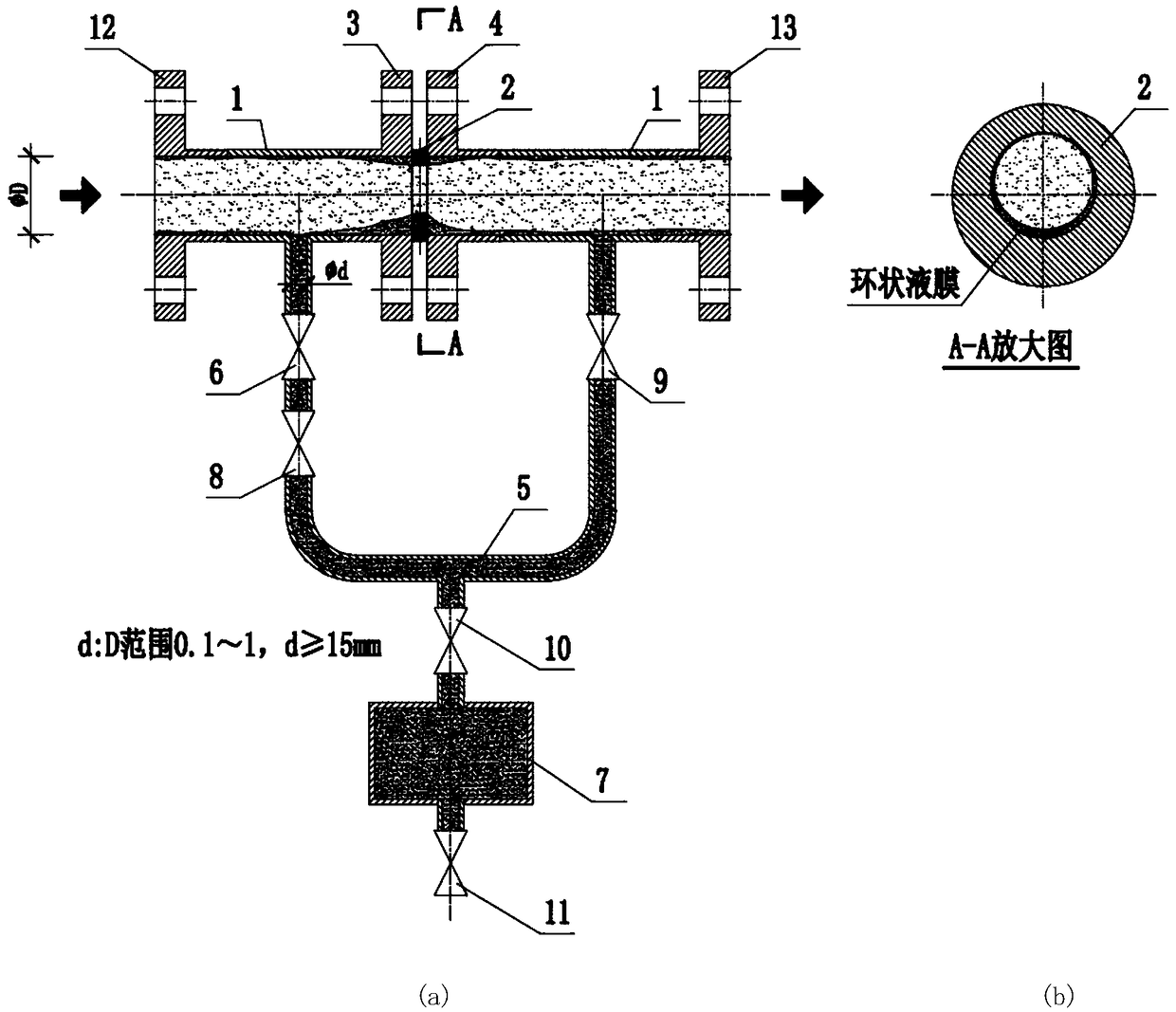

[0019] The present invention is a wet gas liquid phase sampler with an eccentric orifice used in a wet gas multiphase flow measurement device, the schematic diagram of which is as follows figure 1 shown. The principle of the wet gas multiphase flow measurement device is not limited, it can be used for various standard and non-standard throttling devices such as cone, Venturi, nozzle and orifice for wet gas measurement, and can also be used for ultrasonic, mass, In the moisture multiphase measuring device of the principle of thermal type and the like.

[0020] Such as figure 1 shown. The sampler of the present invention is installed on the pipeline where the wet gas flows. The main pipeline 1 of the sampler is the same as the inner diameter of the main pipeline for moisture flow. The eccentric orifice plate 2 is installed on the main pipeline 1 of the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com