Subway permanent magnet traction inverter chopper power module composite busbar

A composite busbar and wave power technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, coupling device, etc., can solve the problems of inconvenient installation, heavy weight, complex structure, etc., and achieve weight reduction , Simple structure, reduce the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

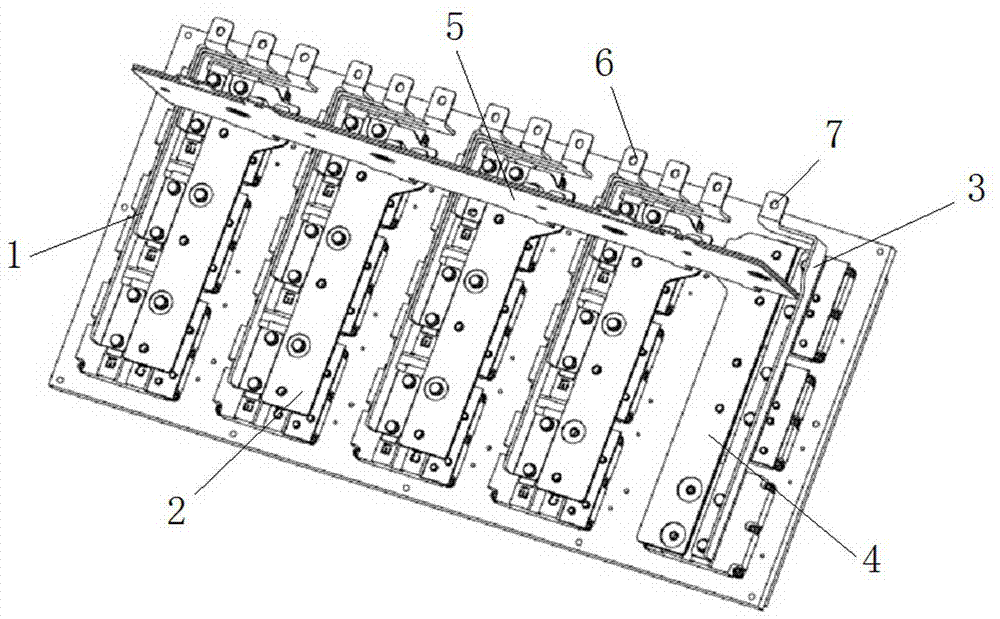

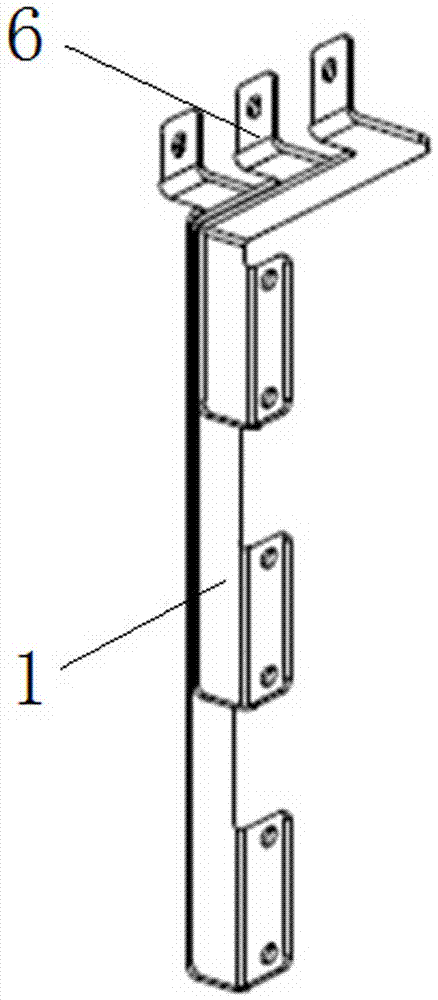

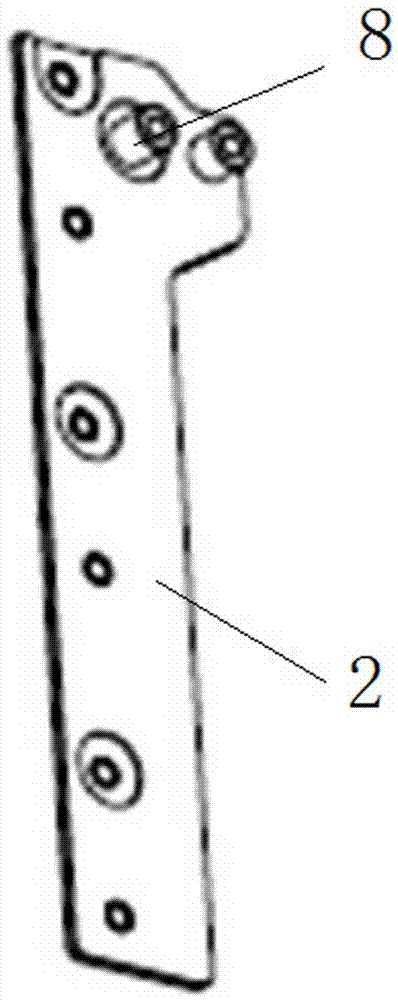

[0015] Metro permanent magnet traction inverter chopper power module composite busbar, including four right-angled inverter output busbars 1 and four inverter DC busbars 2 connected to four sets of inverter circuit power devices correspondingly, and chopper circuit The right-angled chopping resistor busbar 3, the chopping DC busbar 4, the supporting capacitor busbar 5 connected to the power device, and the inverter output busbar 1 are composed of three right-angled copper bar bodies, and each copper bar body The upper end of each is provided with a phase inverter output terminal 6, the chopper resistor busbar 3 is composed of a right-angled copper bar body, and the upper end of the chopper resistor busbar 3 is provided with a chopper output terminal 7, and the inverter DC busbar 2 and the chopping DC busbar 4 are provided with a threaded sleeve 8, the supporting capacitor busbar 5 is vertically arranged with the inverter DC busbar 2, and one end of the supporting capacitor busb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com