Liquid-cooling VPX cabinet efficient heat-dissipation device and method based on vapor chamber

A heat dissipation device and heat dissipation method technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve problems such as leakage and limit heat dissipation of VPX board cards, and achieve improved heat dissipation capacity and small flow resistance , Improve the effect of heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

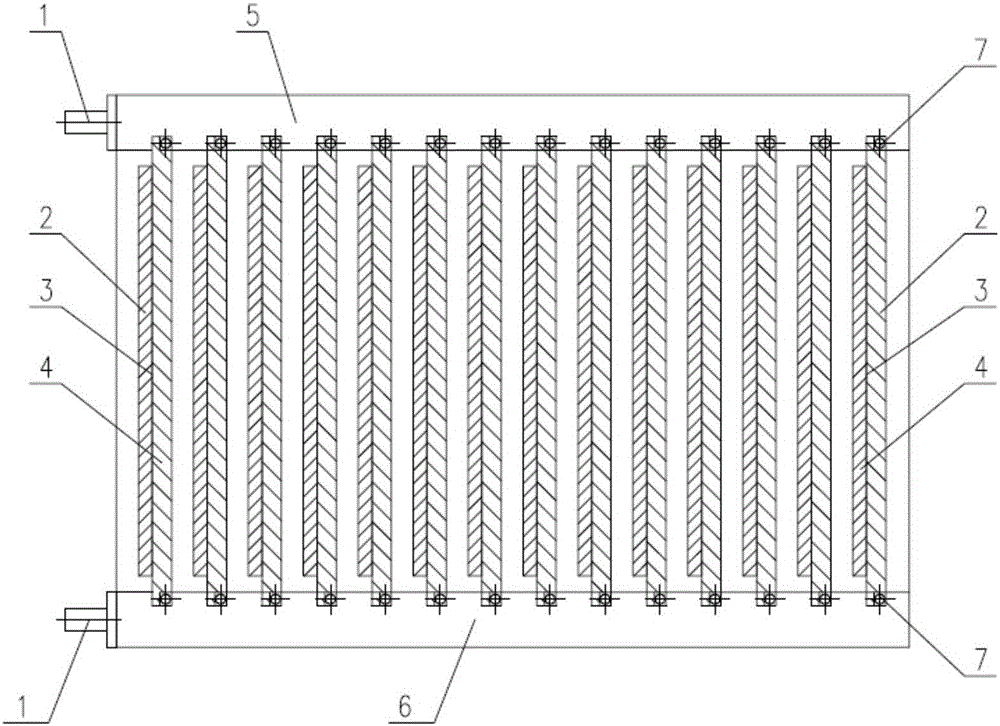

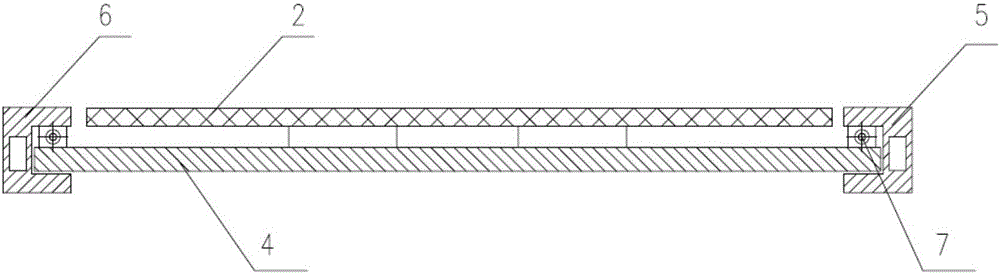

[0016] The structure diagram of the high-efficiency heat dissipation device of the liquid-cooled VPX chassis based on the heat plate figure 1 . For the individual components of the VPX board, the heat flux density is 100-200W / cm 2 For applications where the heat dissipation requirement of a single VPX board card exceeds 100W, it is recommended to use a heat spreader to expand the heat of the VPX board and then dissipate it. The high-efficiency heat dissipation device for the liquid-cooled VPX subrack provided by the present invention includes a quick connector (1), a VPX board (2), an equalizing plate (4), an upper liquid cooling plate (5), a lower liquid cooling plate (6), and a lock Tensioner (7). Among them: the VPX board (2) is fastened to the soaking plate (4), and the heat source of the VPX board (2) contacts the surface of the soaking plate (4) to conduct heat to the soaking plate (4). The upper liquid-cooled cold plate (5) and the lower liquid-cooled cold plate (6) are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com