High aspect boron nitride, methods, and composition containing same

A composition, boron nitride technology, applied to boron nitride with high aspect ratio, can solve the problems of increasing the cost of composite materials, limiting h-BN, affecting processing and mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

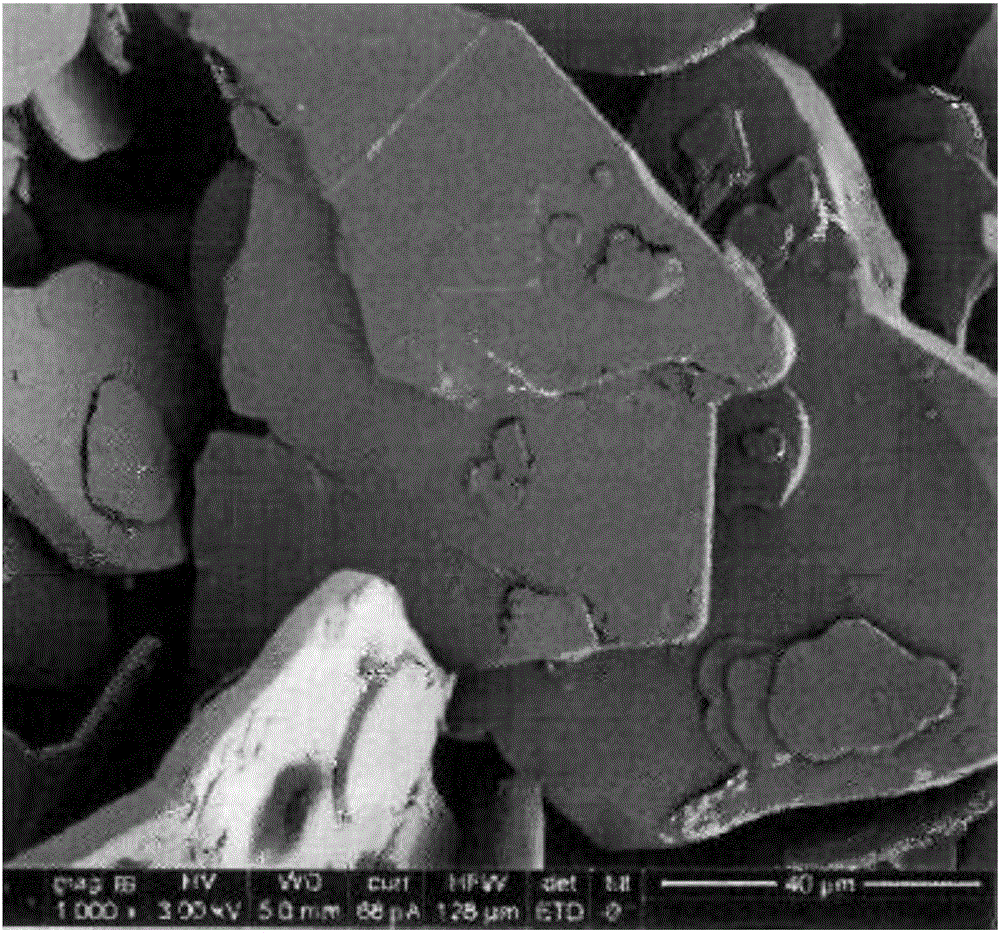

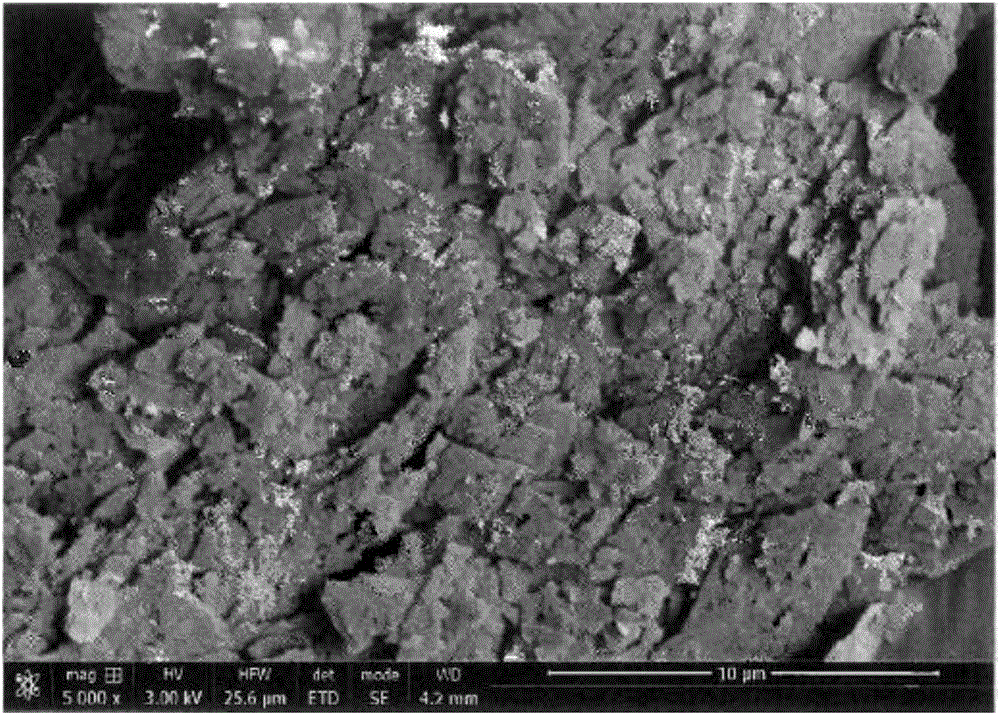

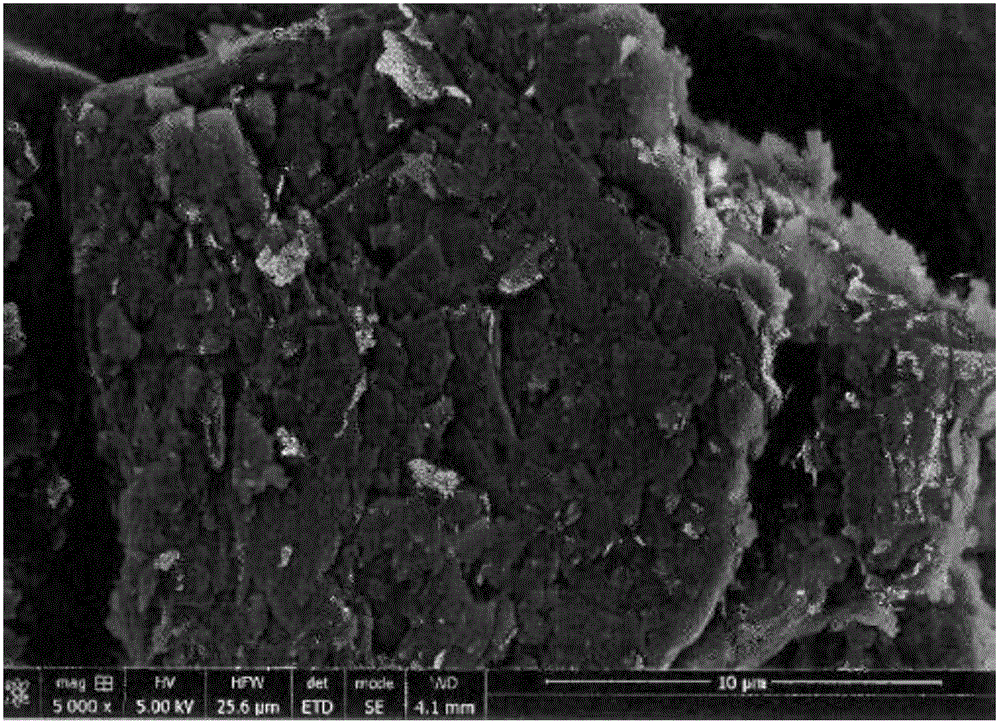

[0075]In one example, h-BN was exfoliated in a suitable carrier using a 3-roll mill: hBN with an average crystal size of 50 microns was mixed with various carriers. Any suitable carrier or combination of carriers selected from the family of substrates, solvents, surfactants, additives that provide beneficial stiction to the boron nitride surface can be chosen. An organic material, an inorganic material, or a combination of two or more thereof may be selected. In this example, honey, cornstarch in water, poly-2-ethyl-2-oxazoline in water and polyvinyl acetate in water were used. hBN was first mixed with solvents at different loadings in a centrifugal mixer to obtain a homogeneous dispersion, and then processed through a 3-roll mill. The 3-roll mill was run at a maximum speed of 400 RPM with an inter-roll distance of 15 microns. Run at least one 3-roll mill, but as many as and including many times. The resulting exfoliated BN is then ashed to remove the support (organic conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com