Honey-flavor modified milk powder

A technology for preparing milk and honey, which is applied in the directions of dairy products, milk preparations, and applications, can solve the problems of poor combination of honey and full-fat milk powder, poor fusion, poor taste, etc. The effect of smooth taste and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

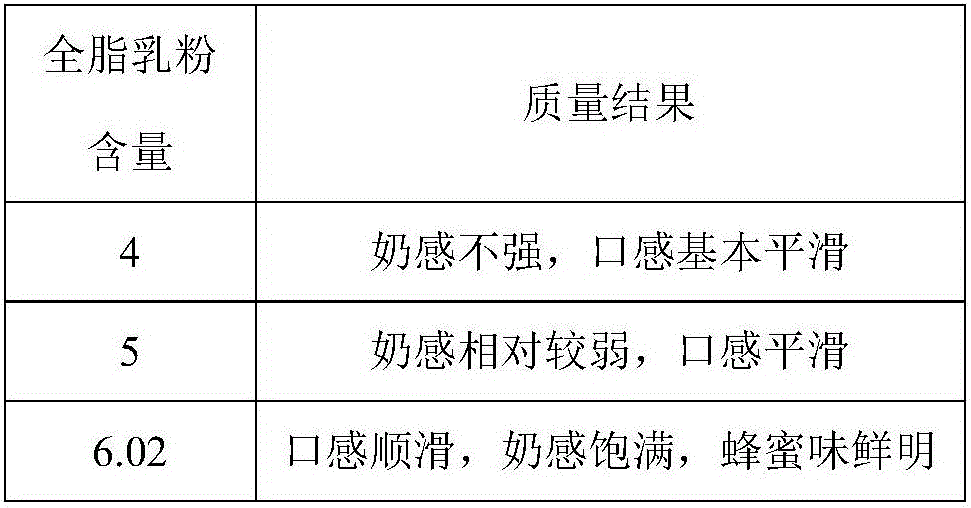

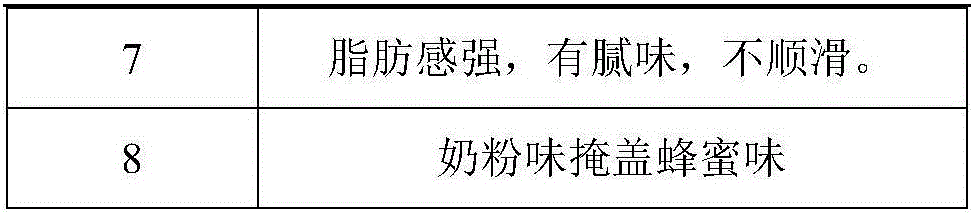

[0023] A honey-flavored milk powder comprises the following raw materials in parts by weight: honey 4.82, fresh milk 86.75, whole milk powder 6.02, skimmed milk powder 1.20, and cream 1.18.

[0024] The preparation method of above-mentioned honey flavor modulation milk powder, comprises the following steps:

[0025] (1) Ingredients: add honey to fresh milk, stir until the honey is fully dissolved, then add cream, stir evenly to obtain a mixture, mix whole milk powder and skimmed milk powder together, stir evenly to obtain a mixture, Pour the mixed solution into the mixed material, and stir evenly under the condition of 70°C to obtain the initial ingredient;

[0026] (2) Homogenization: Homogenize the initial ingredients to obtain the final ingredients;

[0027] (3) Drying: Spray-dry the final ingredients, the inlet air temperature of the spray-drying process is 170°C, and the exhaust air temperature is 85°C;

[0028] (4) Cooling: the dried final ingredients enter the fluidiz...

Embodiment 2

[0030] A honey-flavored milk powder comprises the following raw materials in parts by weight: honey 4, fresh milk 75, whole milk powder 5, skimmed milk powder 0.5, cream 0.5, food essence 0.01.

[0031] The preparation method of above-mentioned honey flavor modulation milk powder, comprises the following steps:

[0032] (1) Ingredients: add honey to fresh milk, stir until the honey is fully dissolved, then add cream, stir evenly to obtain a mixed solution, mix whole milk powder, skim milk powder and food flavor together, stir evenly to obtain Mixed material, pour the mixed solution into the mixed material, and stir evenly under the condition of 65°C to obtain the initial ingredient;

[0033] (2) Homogenization: Homogenize the initial ingredients to obtain the final ingredients;

[0034] (3) Drying: Spray drying is carried out on the final ingredients, the inlet air temperature in the spray drying process is 160°C, and the exhaust air temperature is 80°C;

[0035] (4) Cooling...

Embodiment 3

[0037] A honey-flavored milk powder comprises the following raw materials in parts by weight: honey 6, fresh milk 95, whole milk powder 7, skimmed milk powder 1.5, cream 1.5, food flavor 0.03.

[0038] The preparation method of above-mentioned honey flavor modulation milk powder, comprises the following steps:

[0039] (1) Ingredients: add honey to fresh milk, stir until the honey is fully dissolved, then add cream, stir evenly to obtain a mixed solution, mix whole milk powder, skim milk powder and food flavor together, stir evenly to obtain Mixed material, pour the mixed solution into the mixed material, and stir evenly under the condition of 75°C to obtain the initial ingredient;

[0040] (2) Homogenization: Homogenize the initial ingredients to obtain the final ingredients;

[0041] (3) Drying: Spray-dry the final ingredients, the inlet air temperature of the spray-drying process is 180°C, and the exhaust air temperature is 90°C;

[0042] (4) Cooling: The dried final ingr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com