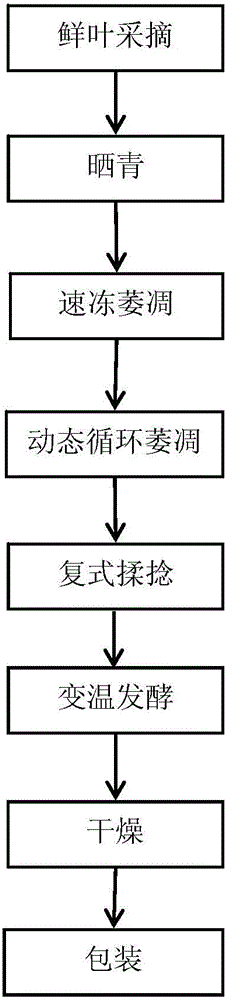

Automatic production process of flower fragrance type Kongfu black tea

A production process, the technology of Kung Fu black tea, applied in the field of automatic production process of flower-flavored Kung Fu black tea, can solve the problems that the production and processing of Kung Fu black tea cannot meet the market demand, the green and astringent taste cannot be removed due to insufficient sunshine time, and the conventional tea process cannot be satisfied. Good shape, solve the effect of dull taste, tight knot and even appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

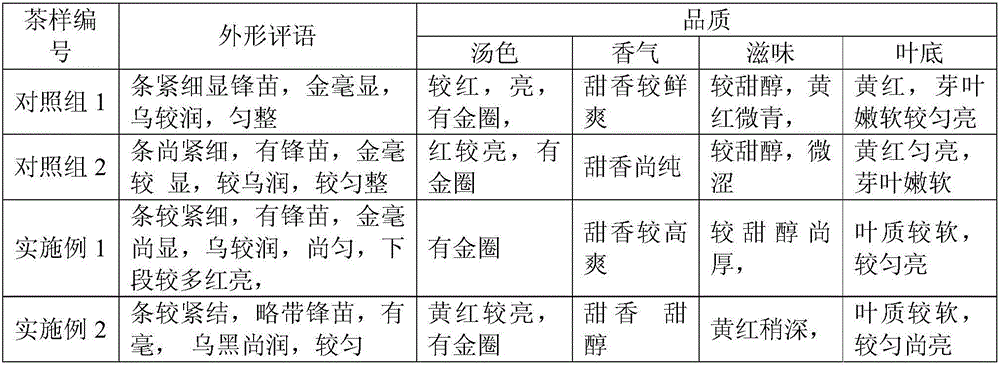

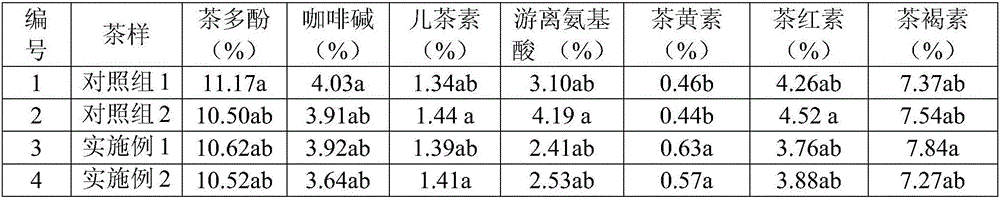

Embodiment 1

[0032] The fresh leaves with one bud and two leaves of the large-leaf tea tree variety are selected as raw materials. After picking, the material is fed from the feeding port through the automatic feeding machine. The thickness of the spread is 1cm-2cm, the conveyor belt in the drying room is distributed in a Z shape, the temperature in the drying room is controlled at 22°C-25°C, and the drying time is controlled within 60min-120min; The mouth is evenly spread on the conveyor belt, and the belt transports the tea green leaves into the quick-freezing cold storage for quick-freezing and withering. The belts in the cold storage are distributed in a Z shape. After the quick-freezing and withering of the green leaves, the green tea leaves are transported to the normal temperature thawing room by the conveyor belt for thawing. The belts in the thawing room are distributed in a Z shape; The feeding bin is equipped with a uniform leaf device, which can control the thickness of fresh l...

Embodiment 2

[0034] The fresh leaves with one bud and three leaves of the large-leaf tea tree variety are selected as raw materials, and the processing steps are exactly the same as in Example 1.

[0035] Control group 1:

[0036] The fresh leaves with one bud and two leaves of the big-leaf tea tree variety are selected as raw materials, and processed by manual frying. The processing steps and conditions are as follows: use sunlight to dry green, choose an outdoor temperature of 22°C to 25°C, and spread the thickness of 1cm to 2cm , the drying time is controlled within 60min~120min; quick freezing and withering in the cold storage, the freezing temperature is -30℃~-18℃, the time is 60min~90min, thawing at room temperature, when there is no ice residue on the surface of the tea green leaves, transfer to manual sunlight withering , thinly spread the fresh tea leaves on the withering curtain to make it disperse water, change from brittle and hard to wilting and withering, and turn to rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com