Cooker and surface treatment process of cooker handle of cooker

A technology for surface treatment and pots, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, kitchen utensils, etc. It can solve the problems of affecting the service life of pot handles, coating the inner wall of the inner hole, and the inner wall of the inner hole is prone to moisture and other problems to achieve the effect of reducing deformation, improving service life and good connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

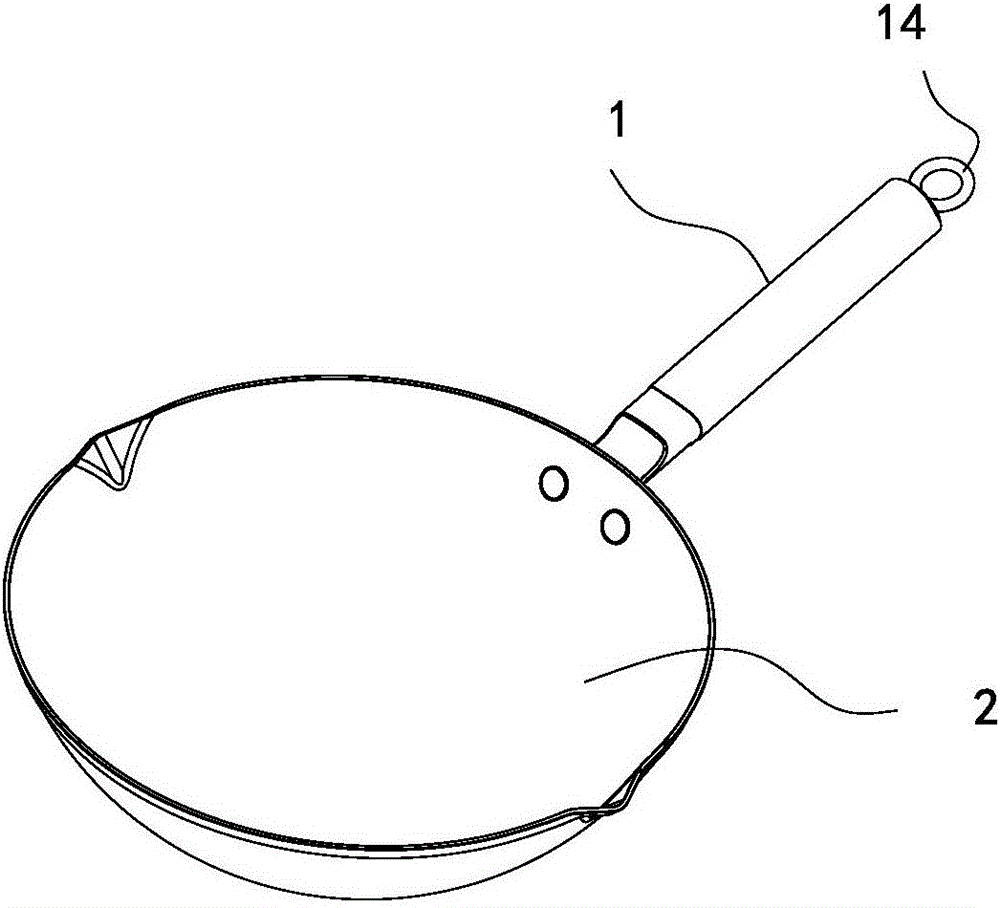

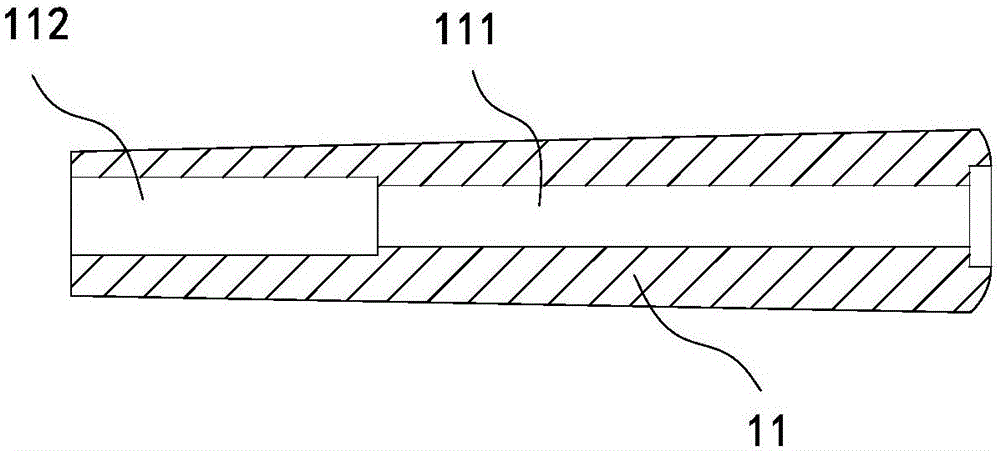

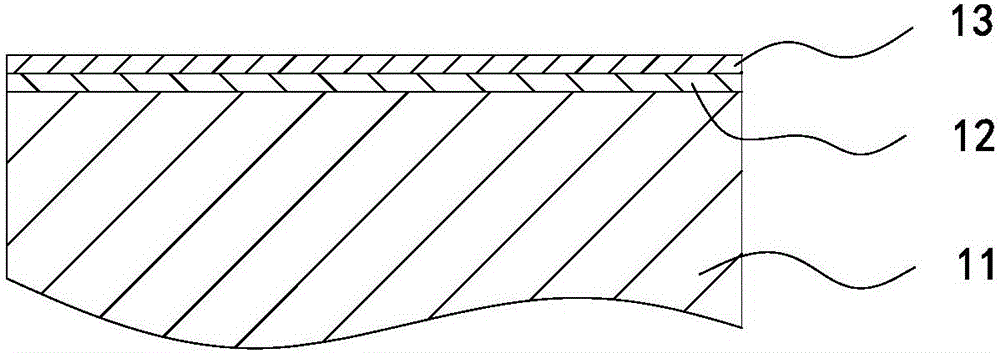

[0034] Embodiment 1, with reference to Figures 1 to 4 , this embodiment is a pot for cooking ingredients, the pot includes a pot handle 1, a pot body 2 and a fastener connecting the pot handle 1 and the pot body 2, the fastener includes a connecting rod, the connecting rod The rod can be a screw, rivet, bolt, etc. with threads provided at least at the end. In this embodiment, the pot handle 1 includes a wooden handle body 11, and the handle body 11 is provided with a mounting bracket for the fastener. In the inner hole 111 , the end of the connecting rod is provided with a suspension ring 14 , the main body of the connecting rod is located in the inner hole 111 , and the suspension ring 14 at the end protrudes out of the inner hole 111 .

[0035] Specifically, the handle body 11 is generally cylindrical, and the inner hole 111 communicates with both ends of the handle body 11. The fastener in this embodiment is a connecting rod with a ring 14 at one end and a thread at the ot...

Embodiment 2

[0052] Example 2, such as Figure 5 As shown, the difference with Example 1 is that in this embodiment, instead of using the soaking process in step S2, the primer is drenched onto the white embryo after the surface is polished, and the drenching process is mainly to hang the white embryo or Place it under the curtain spraying machine, and pour the primer onto the white embryo through the curtain spraying machine.

[0053] The method of showering has the same advantages as the soaking method, and can reduce process steps, less time-consuming, and low cost, and the method of showering is to directly pour the primer onto the handle body 11 without diluting the primer. , more convenient and direct, and the drenching process is usually to hang the drenching, the handle body 11 has less contact with other objects, so that the blind area of the drenching screen is very small, and has little influence on the appearance.

Embodiment 3

[0054] The difference between embodiment 3 and embodiment 1 is that in this embodiment, the entire paint layer of the pot handle 1 only includes the primer layer, and its surface treatment process only goes through steps S1 and S2. The advantage of this embodiment is that, The process is simpler, and for low-end products or products with low requirements, this embodiment can be adopted to improve the market competitiveness of the products.

[0055] At the same time, it should be pointed out here that the pots described in this embodiment include not only woks, frying pans, etc. that are compatible with electric stoves and gas stoves, but also electric pots that are compatible with electric cookers, cooking machines, etc. Compatible inner pots, stew pots, etc., as long as they have wooden handles, can use this solution.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap