Treatment device and method for fermentation dregs of polymyxin sulfate

A polymyxin and treatment method technology, which is applied in the field of treatment equipment for polymyxin sulfate fermentation residue, can solve problems such as pressure on the ecosystem, achieve reduced treatment costs, high degradation capacity, and reduce bacterial resistance risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Mix the original swamp mud with the SRB enrichment medium 1:1, adjust the pH=7, and culture in the dark at a closed temperature of 35°C. Discard the supernatant every day, and supplement with fresh and equal volume of SRB enrichment medium. Co-cultivate in this way for 6 days.

[0061] SRB enriched medium is K 2 HPO 4 ·3H 2 O 0.5g / L, CaCl 2 2H 2 O 0.1g / L, MgSO 4 ·7H 2 O 2g / L, FeSO 4 ·7H 2 O 0.5g / L, NH 4 Cl 1g / L, NaCl 1g / L, sodium lactate 5g / L.

[0062] Mix the polymyxin sulfate fermentation residue and SRB sludge according to the volume of 5:1, and add water to make the solid content TS of the whole mixture system 80g / L, put them into the pretreatment tank for airtight cultivation, control pH=7, The temperature is 35° C., the stirring rate is 100 r / min, and the incubation time is 4 days to complete the pretreatment of the polymyxin sulfate fermentation residue.

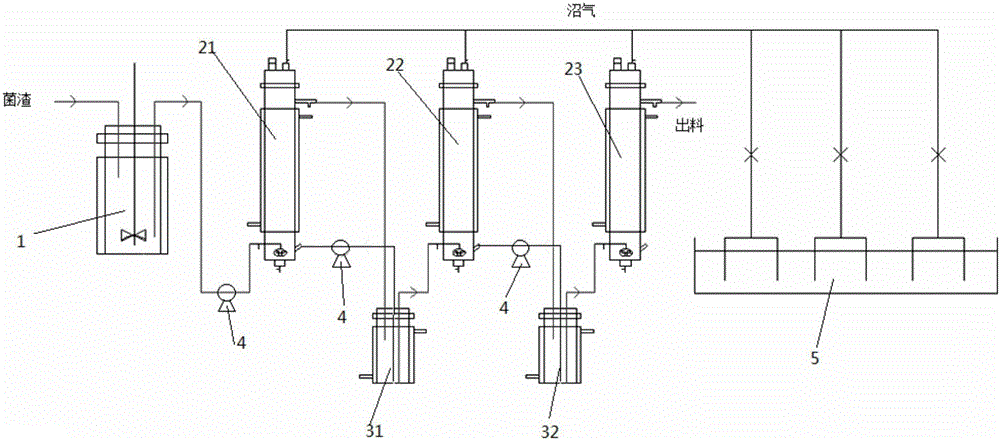

[0063] The pretreated polymyxin sulfate slag was pumped into No. 1 tank, No. 2 tank, and No. 3 ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com