Casting technique of automobile hub

A casting process and technology for automobile wheel hubs, applied in the field of wheel hub casting, can solve the problems of unstable size and uneven composition of aluminum alloy wheels, and achieve the effects of good high temperature resistance, no cracking, stable size and simple formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

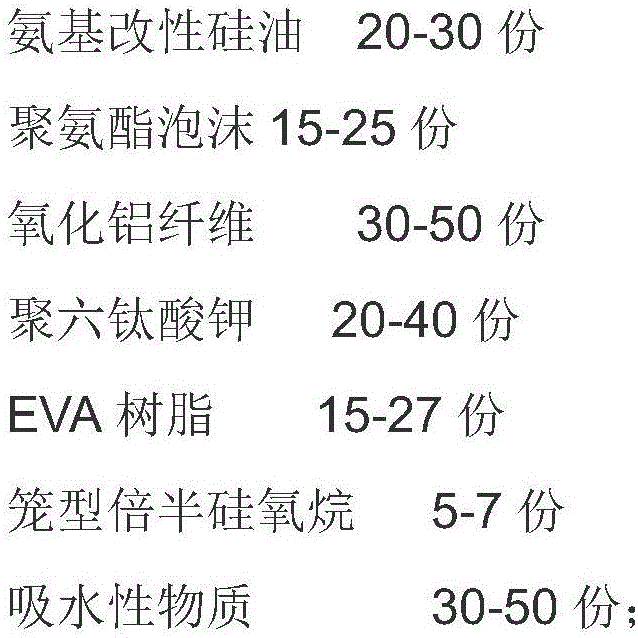

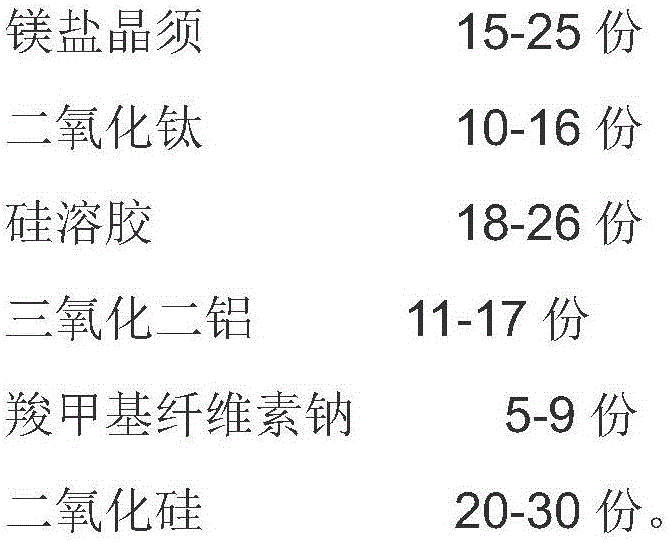

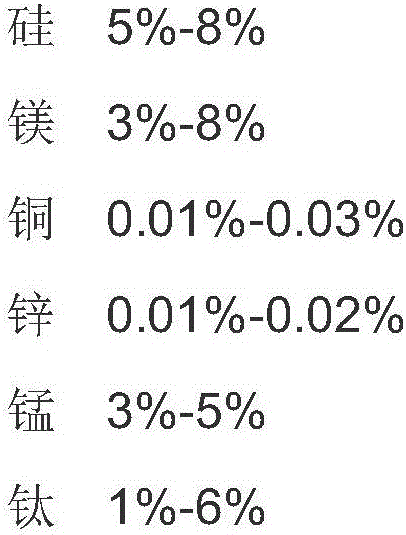

Method used

Image

Examples

Embodiment 1

[0025] a, cleaning the upper mold and the lower mold for casting, and air-drying the upper mold and the lower mold; b, coating the upper mold coating and curing respectively, and coating the lower mold coating on the inner surface of the lower mold and curing; c, weighing aluminum Alloy raw materials, melt and pour the aluminum alloy raw materials, heat the casting mold to 800°C, and pour the molten aluminum alloy raw materials into the casting mold at a pouring speed of 0.61m / s under a constant temperature state; e. Immediately after the pouring is completed Pressurize the casting mold at constant temperature from the sprue, the pressure is 0.01MPa, and the pressurization holding time is 1h; f, the casting mold is cooled in steps, the first stage is to cool the casting mold to 200 °C Finally, keep the temperature constant for 3 hours, and the second stage is to cool the pouring mold to room temperature naturally; g, demoulding treatment, and remove the burr from the workpiece ...

Embodiment 2

[0036] a, cleaning the upper mold and the lower mold for casting, and air-drying the upper mold and the lower mold; b, coating the upper mold coating and curing respectively, and coating the lower mold coating on the inner surface of the lower mold and curing; c, weighing aluminum Alloy raw materials, melt and pour the aluminum alloy raw materials, heat the casting mold to 900°C, and pour the molten aluminum alloy raw materials into the casting mold at a pouring speed of 0.68m / s under a constant temperature state; e. Immediately after the pouring is completed Pressurize the casting mold at constant temperature from the pouring port, the applied pressure is 0.015MPa, and the pressurized holding time is 1.5h; f, carry out step cooling to the casting mold, the first stage is to cool the casting mold to 300 After ℃, keep the temperature for 5 hours, the second stage is to cool the pouring mold to room temperature naturally; g, demoulding treatment, and deburring the workpiece to ob...

Embodiment 3

[0047] a, cleaning the upper mold and the lower mold for casting, and air-drying the upper mold and the lower mold; b, coating the upper mold coating and curing respectively, and coating the lower mold coating on the inner surface of the lower mold and curing; c, weighing aluminum Alloy raw materials, melt and pour the aluminum alloy raw materials, heat the casting mold to 860°C, and pour the molten aluminum alloy raw materials into the casting mold at a pouring speed of 0.65m / s under a constant temperature state; e. Immediately after the pouring is completed Pressurize the casting mold at constant temperature from the pouring port, the applied pressure is 0.012MPa, and the pressurized holding time is 1.2h; f, carry out step cooling to the casting mold, the first stage is to cool the casting mold to 270 After ℃, the temperature is kept constant for 3.5 hours. The second stage is to cool the casting mold to room temperature naturally; g, demoulding treatment, and deburring the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com