Efficient pipe cutting machine for machining

A mechanical processing, high-efficiency technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problem of high operating costs, achieve the effect of solving high operating costs, small land area, and improving production development rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

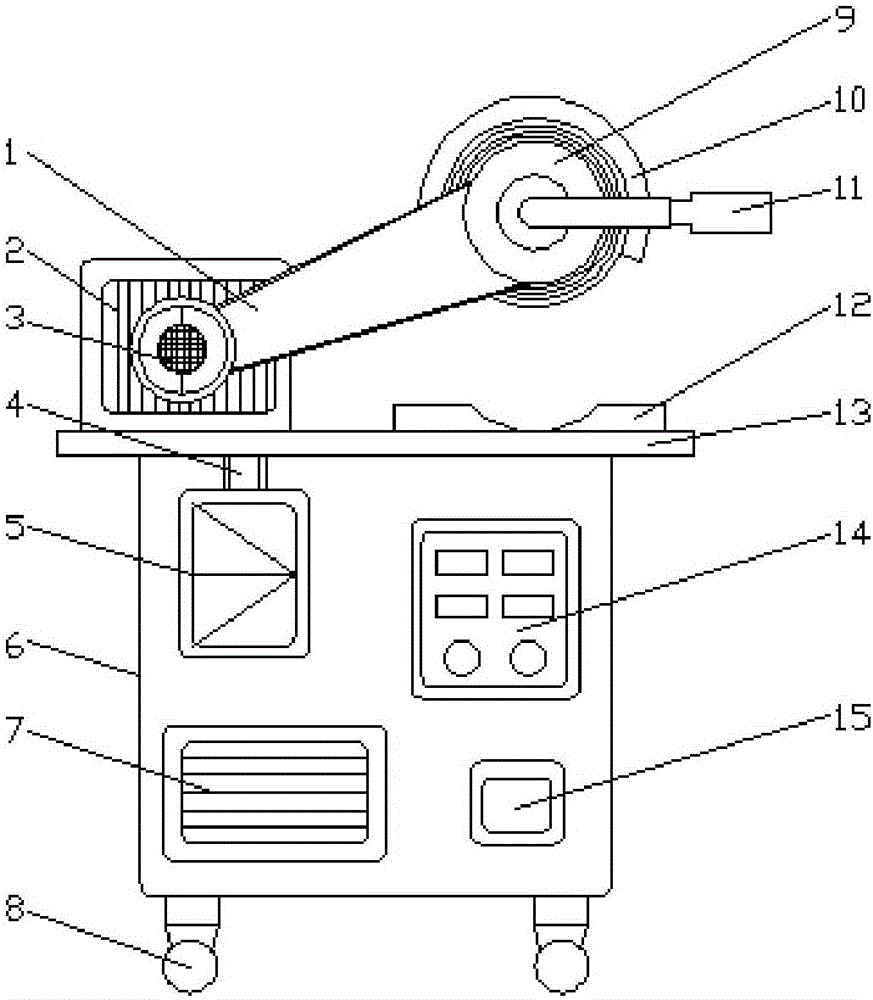

[0014] See figure 1 , The high-efficiency pipe cutting machine for mechanical processing of the present invention includes a driver 1, a rotating shaft 4, a casing 6, a line box 7, a moving pulley 8 and a protective cover 10. in,

[0015] In this embodiment, the driver 1 is connected with the rotator 3, the drive motor 2 is installed on the rotator 3, and the spring return device is arranged in the rotator 3, and the rotatable angle of the rotator 3 is 0-30°.

[0016] The lower position of the driving motor 2 is fixed with a top plate 13, the right side of the driving motor 2 is provided with a workbench 12, the casing 6 is connected with the top plate 13, and the top of the top plate 13 is equipped with a workbench 12, and the bottom of the rotator 4 is fixed with a The processor 5 is electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com