Processing assembly line and processing method for valve special for extreme high voltage transformer by robots

A technology of robotic processing and processing methods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable quality control, low production efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

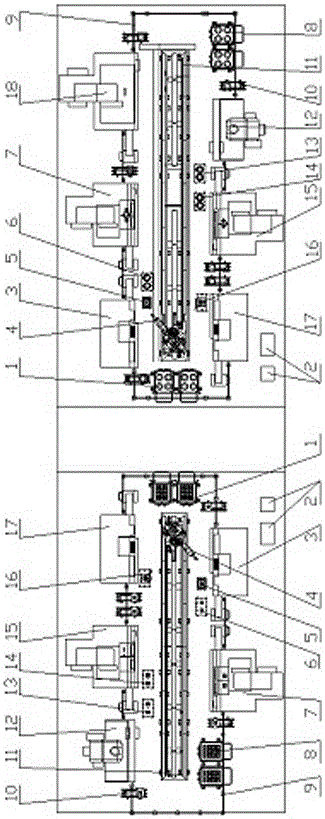

[0080] see figure 1 , the special valve robot processing line for UHV transformers of the present invention is composed of two production lines, the two production lines are similar in that robots and fixtures are installed on the robot guide rails, and the first sequence CNC lathes 3 are respectively arranged on both sides of the robot guide rails. , workpiece rotary positioning table 5, workpiece turnover table 6, third-order machining center 7 and second-order CNC lathe 17, workpiece turning table 16, fourth-order machining center 15, fifth-order square workpiece machining center 12; two production lines The difference is; wherein a production line is also provided with a fifth-order circular workpiece machining center 18; the production line with the fifth-order circular workpiece machining center can process both square workpieces and circular workpieces. Industrial smart cameras and inspection slides, safety fences, pneumatic systems, machine tool fixtures, machine door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com