Handle bar of fine grinding mill

A technology of handle bar and pulverizer, applied in the field of handle bar, can solve the problems of wrong handle bar design, low recycling rate, poor product quality, etc., and achieve the effects of correct design, good recycling and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing:

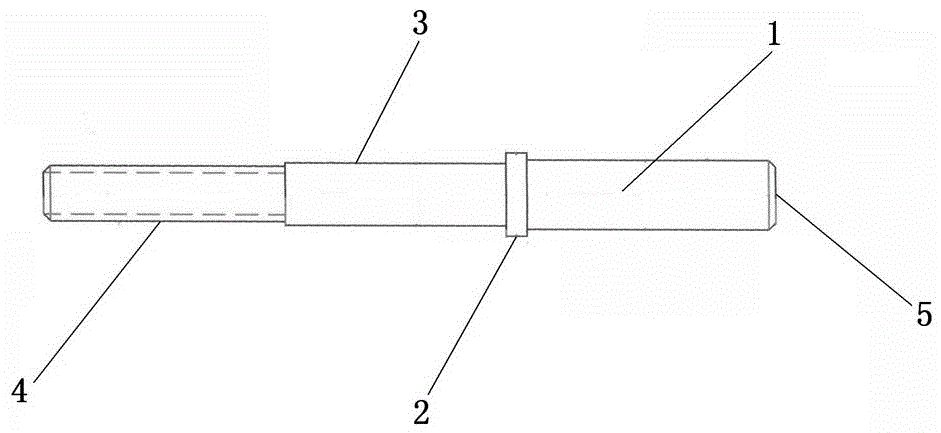

[0008] A handle rod of a fine pulverizer, including a handle and a screw rod, is characterized in that the handle rod is composed of a handle 1, a connecting ring 2, a connecting rod 3, and a screw rod 4; the handle 1 is located on the right of the handle rod, and the handle 1 is cylindrical The shape of the body, placed horizontally, the diameter of the handle 1 is 10mm, and the length of the left and right sides is 36mm; the outer circumference of the right side 5 of the handle 1 is turned into a circle of chamfering at 45°, and the chamfering distance is 1㎜; the left side of the handle 1 is connected to the right side of the connecting ring 2, the connecting ring 2 is in the shape of a cylinder, placed horizontally, the diameter of the connecting ring 2 is 12㎜, and the length of the left and right is 3㎜; the connecting ring 2 and the handle 1 is a concentric circle; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com