Artistic transfer print film for making concrete veneer through set-retarding and eroding

A technology of concrete and transfer film, which is applied in the field of building materials, can solve the problems of poor decoration, achieve low production costs, clear and delicate junctions, and clear and beautiful decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

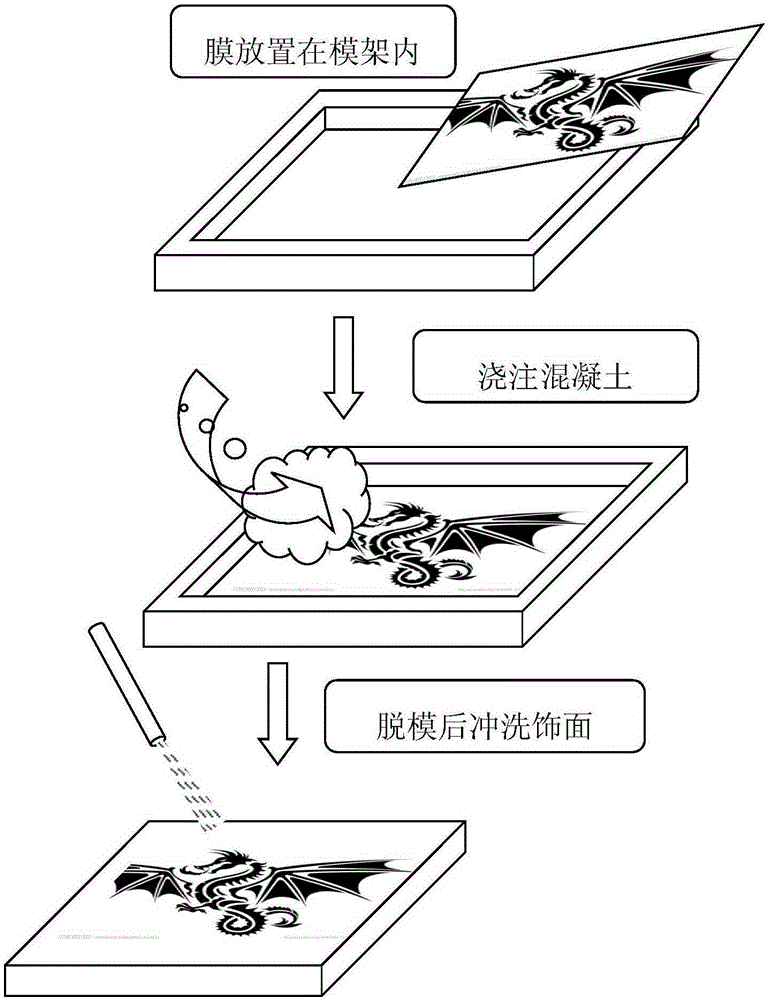

Method used

Image

Examples

Embodiment 1

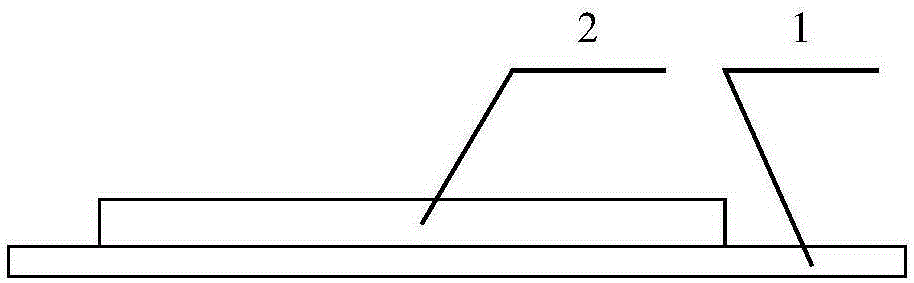

[0025] Example 1: as attached figure 1 As shown in the figure, the art transfer film for concrete washing, corrosion inhibition and curing decoration includes a base film 1 and a setting retarder coating 2, wherein the setting retarder coating 2 is attached to the surface of the base film 1, and the surface area of the setting retarder coating 2 is smaller than that of the base film. 1.

[0026] In the foregoing, the base film 1 is a PVC film with a thickness of 0.3 mm; or, the base film 1 is a PVC film with a thickness of 0.5 mm containing a magnetic backplane.

[0027] In the foregoing, the retarder in the retarder coating 2 is a water-based substance, containing sugar, pigment, thickener and water.

[0028]In the foregoing, the retarder coating 2 is an organic retarder. Among them, the usage amount of the organic retarder is 1 / 100000-8 / 10000 of the mass of the poured concrete slurry. Improper use of more than the metered amount will cause the final strength of the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com