Preparation method of polyurethane-based active heat preservation rigid foam material

A polyurethane-based, active technology, applied in the field of building materials, can solve the problem of not being able to actively increase the ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

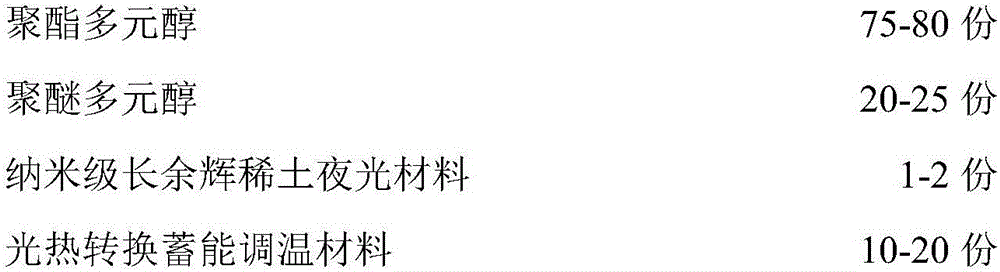

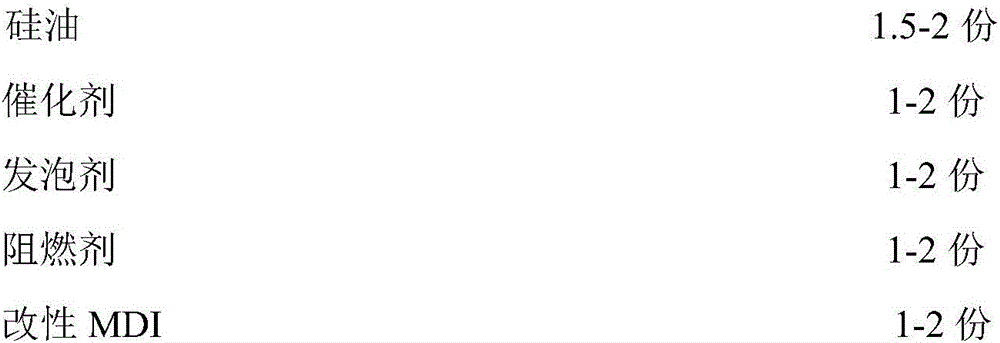

[0023] A preparation method of a polyurethane-based active thermal insulation rigid foam material: polyester polyol, polyether polyol, nano-scale long-lasting rare earth luminous material, light-to-heat conversion energy storage temperature-regulating material, silicone oil, bis-dimethylaminoethyl ether , 1-chloro-3,3,3-trifluoropropene and flame retardant are mixed uniformly according to the following parts by mass:

[0024]

[0025] Adjust the temperature of the system to 30°C, and then mix it with 1.5 parts of modified MDI Bayer 44v20 at high speed, observe that there are bubbles coming out, and when the foam body turns white, inject it into the mold to foam, after swelling, demoulding and post-curing, That is, a polyurethane-based active thermal insulation rigid foam material is obtained.

[0026] Among them, the molecular weight of polyester polyol and polyether polyol is 1300, the hydroxyl value is 400KOH / g, and the functionality is 5.

[0027] Among them, the nanosc...

Embodiment 2

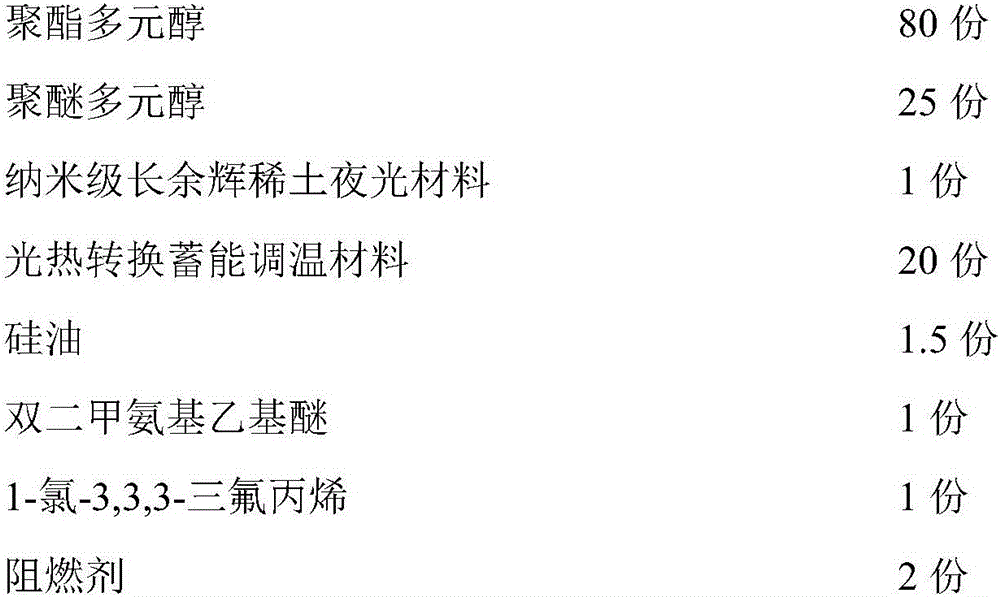

[0039] A method for preparing a polyurethane-based active thermal insulation rigid foam material: polyester polyol, polyether polyol, nano-scale long-lasting rare earth luminous material, light-to-heat conversion energy storage temperature-regulating material, silicone oil, pentamethyldiethylenetriamine , pentafluoropropane and dimethyl methylphosphonate (DMMP) are mixed uniformly according to the following parts by mass:

[0040]

[0041] Adjust the temperature of the system to 18°C, and then mix it with 1 part of modified MDI Yantai Wanhua PM-200 at high speed, observe that there are bubbles coming out, and when the foam body turns white, pour it into the mold and foam, after swelling and demoulding And after curing, the polyurethane-based active thermal insulation rigid foam material is obtained.

[0042] Among them, the molecular weight of polyester polyol and polyether polyol is 800, the hydroxyl value is 430KOH / g, and the functionality is 3.

[0043] Among them, the ...

Embodiment 3

[0053] A method for preparing a polyurethane-based active thermal insulation rigid foam material: polyester polyol, polyether polyol, nano-scale long-lasting rare earth luminous material, light-to-heat conversion energy storage temperature-regulating material, silicone oil, dibutyltin dilaurate, and ring Pentane and ammonium polyphosphate (APP) are mixed homogeneously according to the following parts by mass:

[0054]

[0055]

[0056] Adjust the temperature of the system to 25°C, and then mix it with 2 parts of modified MDI BASF M20S at high speed, observe that there are bubbles coming out, and when the foam body turns white, inject it into the mold to foam, and after swelling, demoulding and post-curing, That is, a polyurethane-based active thermal insulation rigid foam material is obtained.

[0057] Among them, the molecular weight of polyester polyol and polyether polyol is 1200, the hydroxyl value is 420KOH / g, and the functionality is 8.

[0058] Among them, the na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com