Electric networking control method

A networked control, electrical technology, applied in program control, computer control, general control system, etc., can solve the problems of grounding or leakage, equipment damage, cable burning, etc., to achieve less usage, eliminate cable burning, and reliable control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

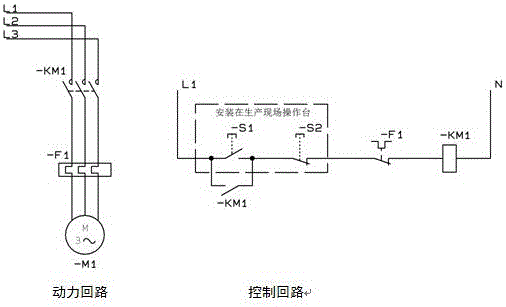

[0014] In actual production, the traditional relay and contactor control systems have various control systems such as controlling the one-way operation of the motor, controlling the forward and reverse operation of the motor, and Y-△ start control. The electrical connection methods are basically the same. In this embodiment, only one relay and contactor control system for controlling the one-way operation of the motor is used as an example for illustration. In addition, in actual production, the control devices used in the on-site operation desk include various control devices such as button switches, universal transfer switches, and master controllers. In this embodiment, only the button switch is taken as an example for illustration.

[0015] Such as figure 1 As shown, it is the electrical schematic diagram of the traditional relay and contactor control system that controls the one-way operation of the motor. Among them, S1 and S2 are button switches installed on the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com