Paper filled with rosette-type precipitated calcium carbonate

A light calcium carbonate, petal-shaped technology, used in calcium carbonate/strontium/barium, papermaking, textiles and papermaking, etc., can solve the problems of poor strength and easy to grow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

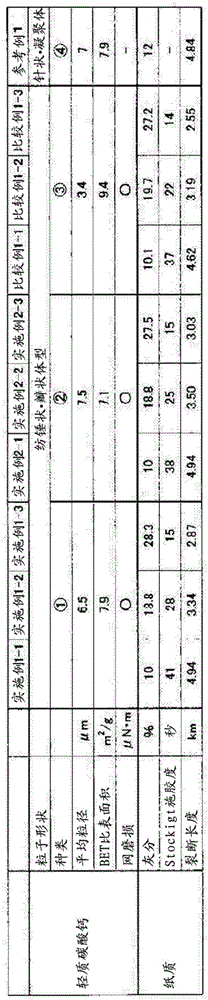

[0075] Hereinafter, although an Example is given and this invention is demonstrated concretely, it goes without saying that this invention is not limited to these. In addition, in this specification, unless otherwise specified, "%" is "% by weight", and the numerical range includes the endpoint.

[0076] Evaluation method

[0077] Each item was evaluated by the following evaluation method.

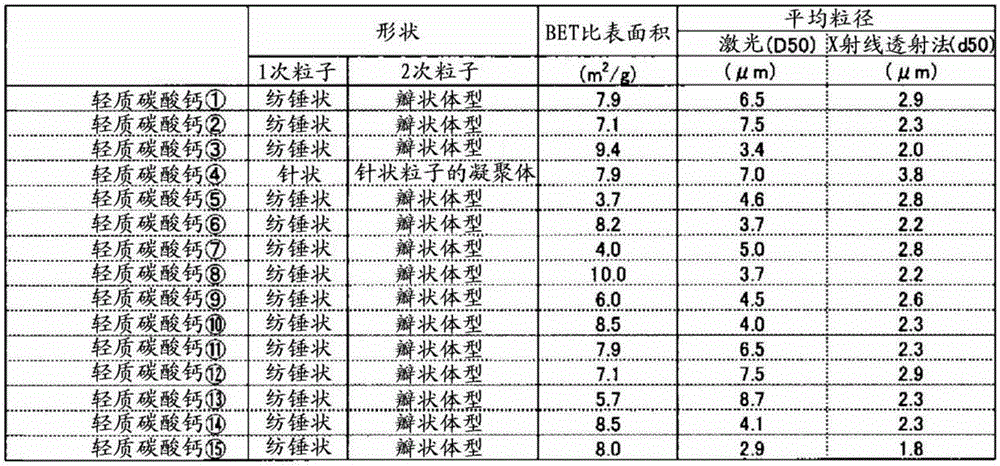

[0078] (1) Average particle diameter: using a laser diffraction / scattering particle size distribution analyzer (manufactured by Malvern, Mastersizer 2000), the 50% point (D50) of the volume cumulative distribution was defined as the average particle diameter.

[0079] (2) Measured in accordance with BET specific surface area: JIS Z 8830-2001.

[0080] (3) Basis weight: measured in accordance with JIS P 8124.

[0081] (4) Paper thickness: Measured in accordance with JIS P 8118.

[0082] (5) Density: Calculated from basis weight and paper thickness according to JIS P 8118.

[0083] (6) ...

reference example 1

[0097] As a reference example, paper was produced using calcium carbonate (calcium carbonate 4: smaller in specific surface area than rosette-shaped calcium carbonate of the same particle size) in which needle-shaped primary particles aggregated to form secondary particles. 0.8% of cationized starch, 0.5% of aluminum sulfate, and 0.1% of alkyl ketene dimer were sequentially added to the pulp absolute dry weight while stirring a slurry of 100% hardwood bleached kraft pulp adjusted to a Canadian standard freeness of 450 mL. , adding light calcium carbonate 4 (average particle size 7.0 μm, BET specific surface area 7.9m 2 / g). After diluting the pulp slurry, add 0.1% retention enhancer relative to the absolute dry weight of the pulp to make paper stock, and use a square sheet former for hand-sheeting to obtain a basis weight of 60g / m 2 of paper. After pressing, it was dried at 110° C. with a drum dryer, and processed so that the paper thickness was 90 μm with a manual cold cale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com