Upflow anti-blocking method and device for dense medium shallow tank separator

A dense-medium shallow tank and separator technology, applied in chemical instruments and methods, solid separation, wet separation, etc., to achieve the effects of preventing adhesion deposition, reducing mismatches, and relieving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

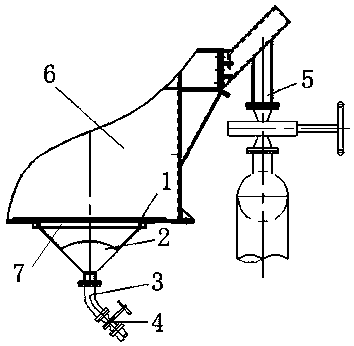

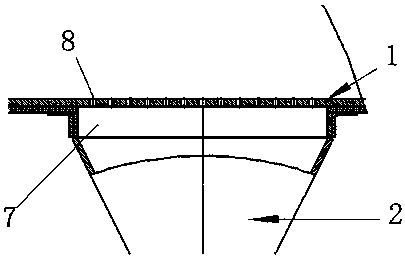

[0036] It can be seen from the accompanying drawings that the present invention relates to an upflow anti-blocking device for a dense medium shallow tank sorter, which includes a dense medium shallow tank sorter tank body 6 and is arranged beside the dense medium shallow tank sorter tank body 6 There is a horizontal flow pipe 5, and an opening 7 is provided on the bottom surface of the lower part of the tank body 6 of the dense medium shallow tank sorter. 2 and the lower opening 7 of the tank body 6 of the heavy medium shallow tank sorter is provided with a flow distribution plate 1; The flow enters the tank body 6 of the dense medium shallow tank separator through the ascending flow distribution orifice 8 .

[0037] Further, the upflow distribution orifice 8 of the above-mentioned flow distribution plate 1 is correspondingly arranged above each upflow hopper of the dense medium shallow tank separator.

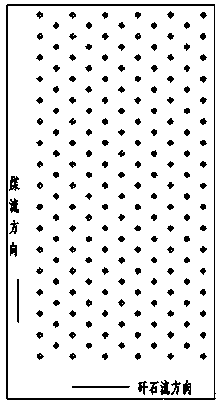

[0038] Further, the arrangement of the upflow distributing orifices 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com