Cross-scale macro-micro coinjection molding rapid molding method based on tungsten metal mold core

A metal tungsten and co-injection molding technology, applied in the direction of coating, etc., can solve the problems of obvious weld lines, internal pores, high cost, etc., and achieve the effects of reducing costs, improving mold life, and improving line accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below through specific embodiments and accompanying drawings.

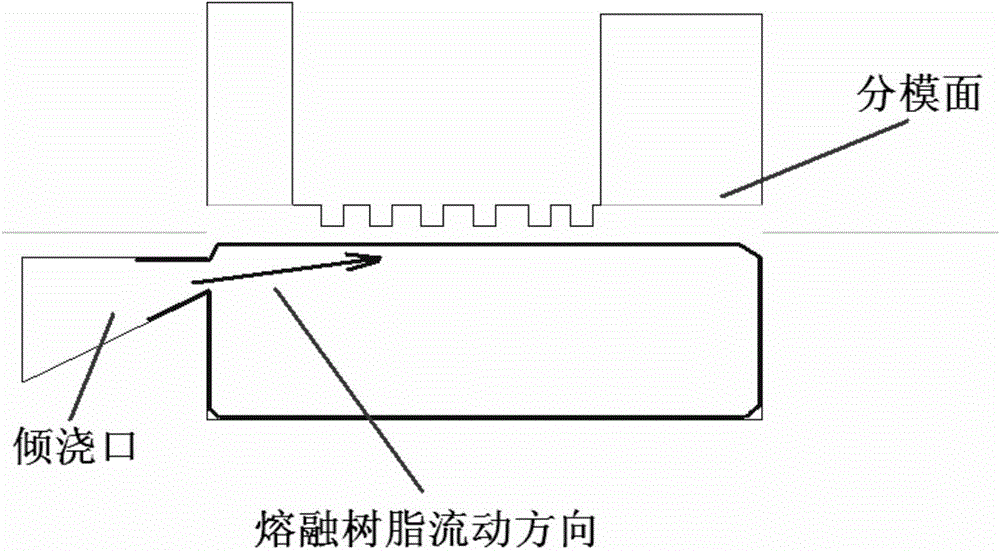

[0040] Based on metal tungsten etching technology, the present invention proposes a cross-scale macro-micro co-injection rapid prototyping process method based on metal tungsten mold core, and realizes a high-precision, high-life and low-cost injection molding process spanning four orders of magnitude.

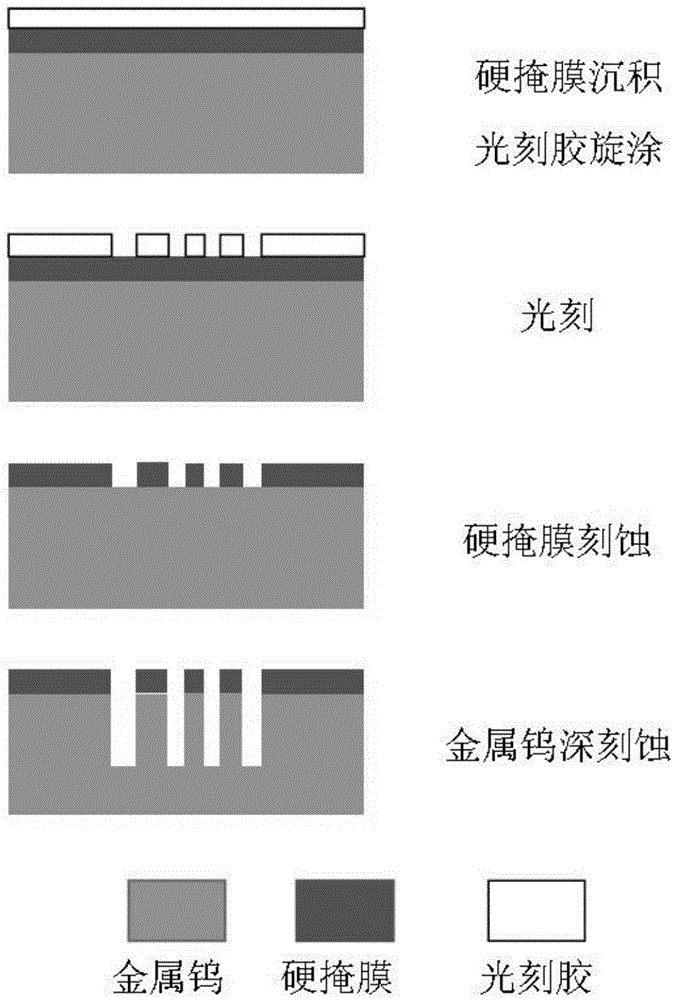

[0041] Metal tungsten has high hardness, large Young's modulus, and good high-temperature properties. It is a natural mold material. Patent CN102372250 proposes a method for etching metal tungsten materials, making it possible to use metal tungsten materials as micron-scale molds.

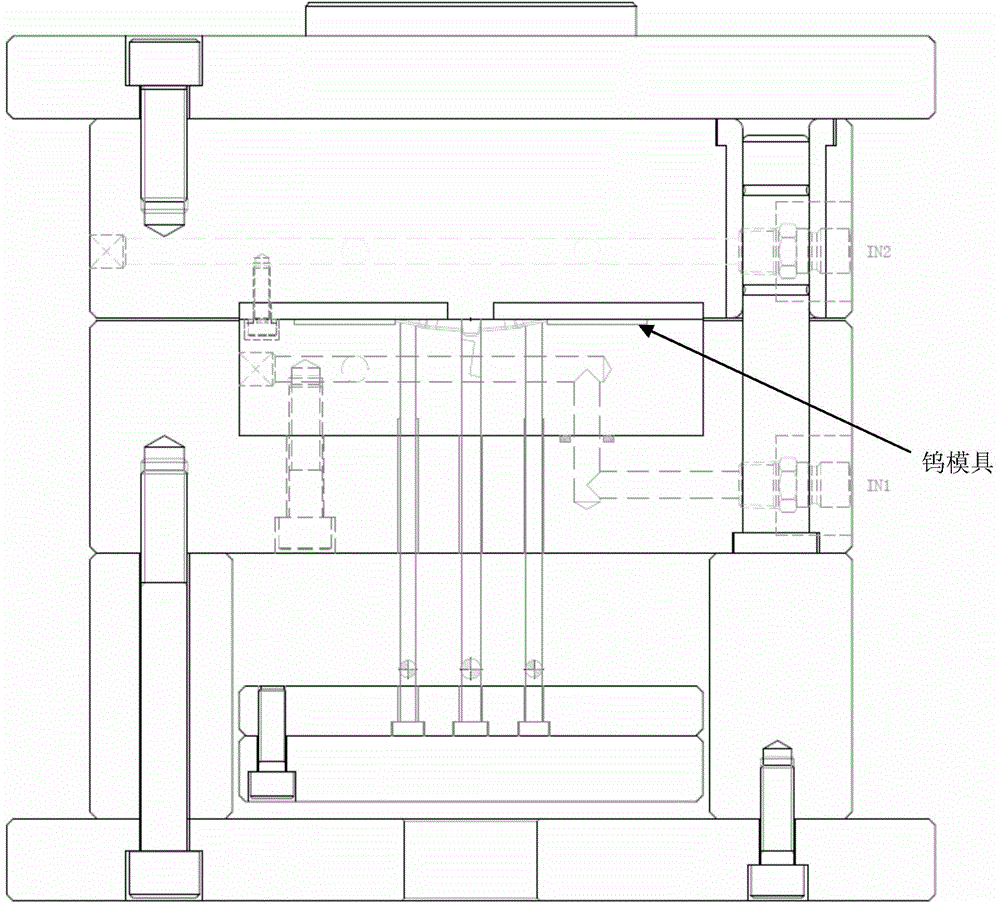

[0042] Since metal tungsten is a material that is mechanically difficult to process macroscopically, when more macro-scale mold processing is required, mold inlay technology is required, and tungsten micro-molds are used as mold cores and fixed molds for injection molding. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com