Preparation method of composite anti-electroplating mask

An anti-plating and masking technology, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of production failure, easy dissolution of photoresist, degumming, etc., and achieves simple methods, high graphics resolution, and lines high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

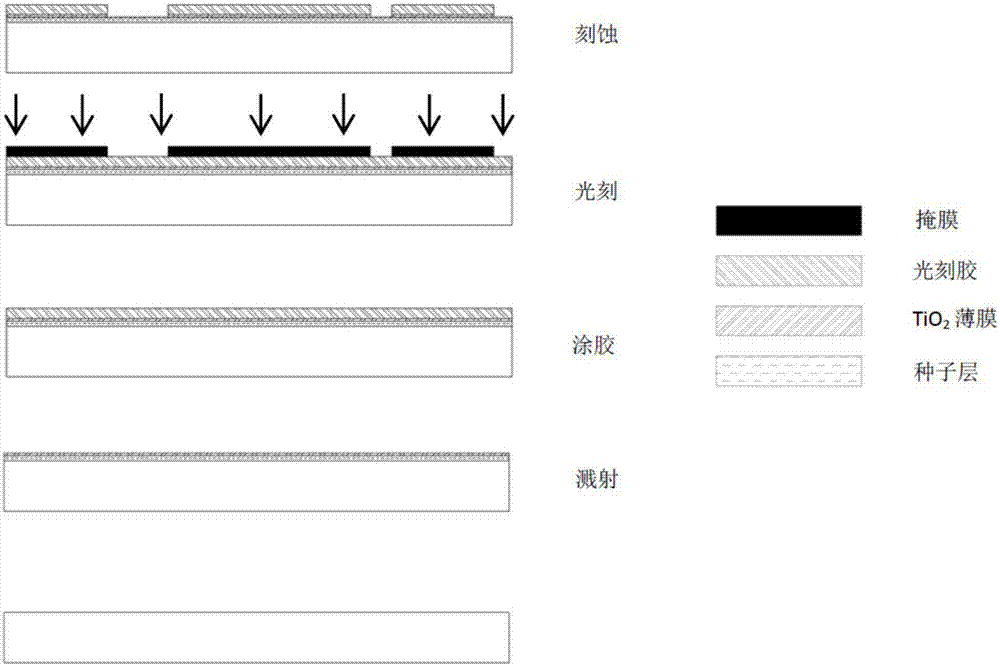

[0025] A kind of preparation method of composite anti-plating mask provided by the invention comprises the following steps:

[0026] (1) Sputtering

[0027] The cleaned Al 2 o 3 The ceramic substrate is placed in the magnetron sputtering coating chamber, and Cr, Cu, TiO are sequentially sputtered 2 Three-layer film, in which Cr film thickness is 50-100nm, Cr and Cu gradient transition layer thickness is 50-100nm, Cu film thickness is 400-500nm, TiO 2 The film thickness is 200-300nm. The sputtering power was 300W, and the Ar flow rate was 100 sccm.

[0028] (2) spray glue

[0029] Place the ceramic substrate with the metal / oxide film deposited in the previous step in the glue sprayer, and spray the diluted positive photoresist. The positive photoresist is AZ4620 from Anzhi Company, and the diluent is methyl ethyl ketone and PGMEA. The degree is based on the fact that the viscosity of the photoresist is less than 0.03 Pa·S, and the rotation speed of the substrate is 50 rpm...

Embodiment 1

[0056] A preparation method of a composite anti-plating mask, comprising the following steps:

[0057] (1) Sputtering

[0058] Place the cleaned ceramic substrate in the magnetron sputtering coating chamber, and the chamber is evacuated to 3.7×10 -4 Pa, turn on the heating, bake and dehumidify the substrate, the baking time and temperature are 250°C and 30min, respectively, and start sputtering deposition of Cr, Cu, TiO 2 Three-layer film, in which Cr and Cu are the circuit seed layer, co-sputtered Cr / Cu interlayer between Cr and Cu, TiO 2 For anti-plating film. Sputtering power is 300W, Ar flow rate is 100sccm, Cr film thickness is 60nm, Cr and Cu gradient transition layer thickness is 50nm, Cu film thickness is 400nm, TiO 2 The film thickness is 200 nm.

[0059] (2) spray glue

[0060] Place the ceramic substrate deposited with the seed layer in the glue sprayer, and spray the diluted positive photoresist. The photoresist is AZ4620 from Anzhi Company, and the diluent is...

Embodiment 2

[0070] A preparation method of a composite anti-plating mask, comprising the following steps:

[0071] (1) Sputtering

[0072] Place the cleaned ceramic substrate in the magnetron sputtering coating chamber, and the chamber is vacuumed to 3.5×10 -4 Pa, turn on the heating, bake and dehumidify the substrate, the baking time and temperature are 250°C and 30min, respectively, and start sputtering deposition of Cr, Cu, TiO 2 Three-layer film, in which Cr and Cu are the circuit seed layer, co-sputtered Cr / Cu interlayer between Cr and Cu, TiO 2 For anti-plating film. Sputtering power is 300W, Ar flow rate is 100sccm, Cr film thickness is 50nm, Cr and Cu gradient transition layer thickness is 50nm, Cu film thickness is 450nm, TiO 2 The film thickness is 220 nm.

[0073] (2) spray glue

[0074] Place the ceramic substrate deposited with the seed layer in the glue sprayer, and spray the diluted positive photoresist. The photoresist is AZ4620 from Anzhi Company, and the diluent is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com