Two-way stretch polyester film for compounding tinned sheet and preparation method of two-way stretch polyester film

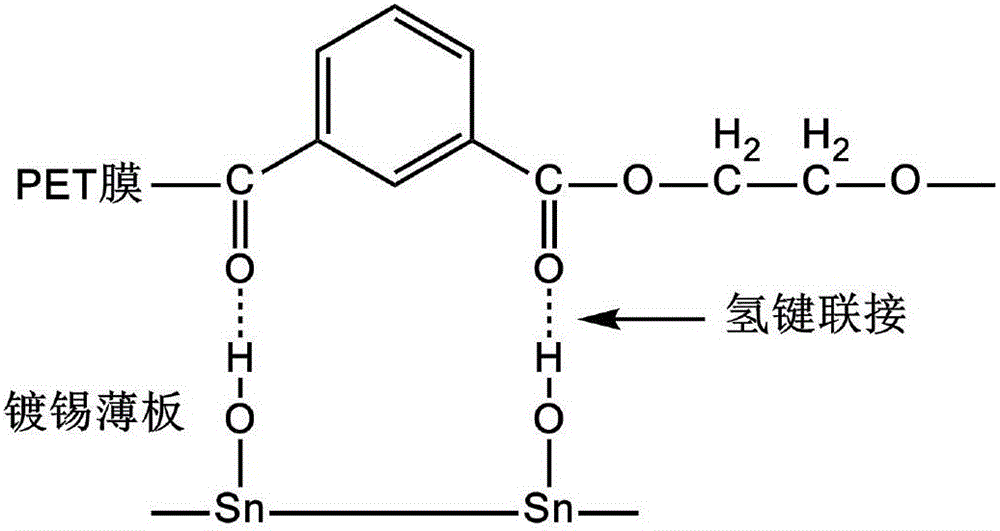

A biaxially stretched polyester and tin-plated sheet technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of elongation at break, thermal stability of heat sealing performance, etc. problems, to avoid the problem of chemical glue migration, to improve the effect of heat setting, and to achieve the effect of high fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

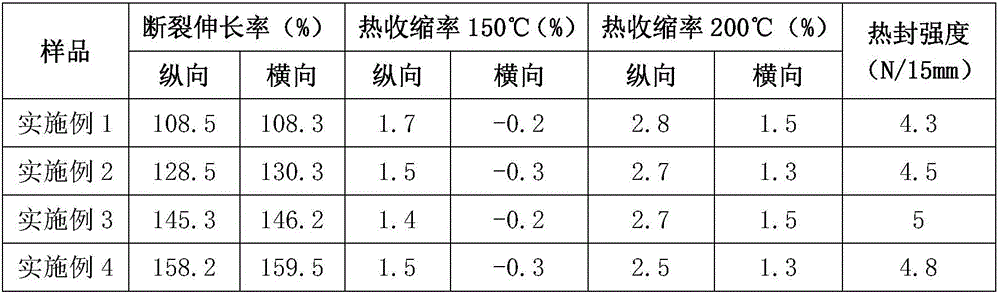

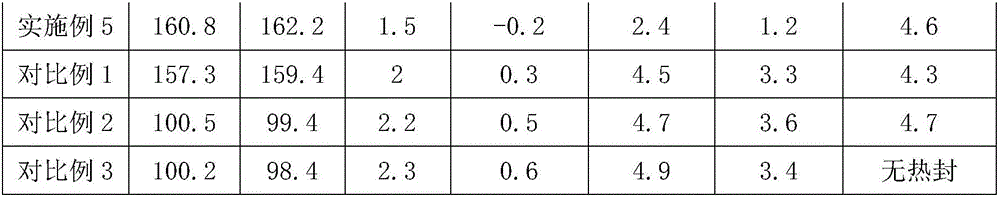

Examples

Embodiment 1

[0039] The upper surface layer is composed of polyester chips and polyester anti-adhesive agent, and the proportion of polyester anti-adhesive agent is 0.2% by weight percentage, and the balance is polyester chips; the lower surface layer is composed of PETG chips and polyester anti-adhesive agent, wherein The polyester anti-adhesive agent content is 0.2%, and the balance is PETG chips; the core layer is composed of copolymerized polypropylene chips, polyester chips and vinyl-terminated polyester, of which 5% is copolymerized polypropylene chips, vinyl-terminated polyester The content is 5%, and the balance is polyester chips.

[0040] The film is carried out as follows:

[0041] (1) Dry the polyester chips through a fluidized bed at 140-160°C for at least 20 minutes, and then dry them in a drying tower at 140-160°C for 2-6 hours;

[0042](2) drying the copolymerized polypropylene slices at 30-90°C for 2-2.5 hours;

[0043] (3) Mix the dried polyester chips, copolymerized po...

Embodiment 2

[0053] The upper surface layer is composed of polyester chips and polyester anti-adhesive agent, and the proportion of polyester anti-adhesive agent is 0.2% by weight percentage, and the balance is polyester chips; the lower surface layer is composed of PETG chips and polyester anti-adhesive agent, wherein The content of polyester anti-adhesive agent is 0.2%, and the balance is PETG chips; the core layer is composed of copolymerized polypropylene, vinyl-terminated polyester and polyester chips, of which the content of copolymerized polypropylene is 10%, and the content of vinyl-terminated polyester is 0.5%, and the balance is polyester chips.

[0054] Its production method is the same with embodiment 1.

Embodiment 3

[0056] The upper surface layer is composed of polyester chips and polyester anti-adhesive agent, and the proportion of polyester anti-adhesive agent is 0.2% by weight percentage, and the balance is polyester chips; the lower surface layer is composed of PETG chips and polyester anti-adhesive agent, wherein The polyester anti-sticking agent content is 0.2%, and the balance is PETG chips; the core layer is composed of copolymerized polypropylene chips, vinyl-terminated polyester and polyester chips, of which copolymerized polypropylene chips are 15%, vinyl-terminated polyester The content is 2%, and the balance is polyester chips.

[0057] Its production method is the same with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap