Zinc alloy electrolytic copper stripping agent

The technology of zinc alloy and complexing agent is applied in the field of zinc alloy electrolytic copper stripping agent, which can solve the problems affecting the recycling of workpieces, easy to corrode workpieces, waste gas pollution, etc., and achieve the effects of convenient transportation, corrosion inhibition, and high current efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

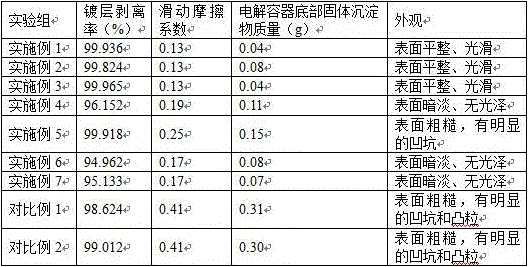

Examples

Embodiment 1

[0036] Present embodiment provides a kind of zinc alloy electrolytic copper stripping agent, and its raw material comprises by weight:

[0037] Oxidizing agent: 85 parts;

[0038] Conductive salt: 150 parts;

[0039] Corrosion inhibitor: 45 parts;

[0040] The first complexing agent: 16 parts;

[0041] The second complexing agent: 4 parts;

[0042] Buffer: 30 parts;

[0043] Wherein, the oxidizing agent is nitrate, the conductive salt is pyrophosphate, the corrosion inhibitor is imidazolium salt, the first complexing agent is alcohol compound, and the second complexing agent is alcohol amine salt, and the buffer is acetate.

[0044] In this embodiment, the oxidant is ammonium nitrate, the conductive salt is calcium pyrophosphate, the corrosion inhibitor is 1-propyl-3-methylimidazolium chloride, and the first complexing agent is mannitol , the second complexing agent is triethanolamine, and the buffering agent is calcium acetate.

Embodiment 2

[0046] Present embodiment provides a kind of zinc alloy electrolytic copper stripping agent, and its raw material comprises by weight:

[0047] Oxidizing agent: 85 parts;

[0048] Conductive salt: 100 parts;

[0049] Corrosion inhibitor: 45 parts;

[0050] The first complexing agent: 16 parts;

[0051] The second complexing agent: 4 parts;

[0052] Buffer: 30 parts;

[0053]Wherein, the oxidizing agent is nitrate, the conductive salt is pyrophosphate, the corrosion inhibitor is imidazolium salt, the first complexing agent is alcohol compound, and the second complexing agent is alcohol amine salt, and the buffer is acetate.

[0054] In this embodiment, the oxidant is ammonium nitrate, the conductive salt is calcium pyrophosphate, the corrosion inhibitor is 1-propyl-3-methylimidazolium chloride, and the first complexing agent is mannitol , the second complexing agent is triethanolamine, and the buffering agent is calcium acetate.

Embodiment 3

[0056] Present embodiment provides a kind of zinc alloy electrolytic copper stripping agent, and its raw material comprises by weight:

[0057] Oxidizing agent: 85 parts;

[0058] Conductive salt: 150 parts;

[0059] Corrosion inhibitor: 30 parts;

[0060] The first complexing agent: 16 parts;

[0061] The second complexing agent: 4 parts;

[0062] Buffer: 30 parts;

[0063] Wherein, the oxidizing agent is nitrate, the conductive salt is pyrophosphate, the corrosion inhibitor is imidazolium salt, the first complexing agent is alcohol compound, and the second complexing agent is alcohol amine salt, and the buffer is acetate.

[0064] In this embodiment, the oxidant is ammonium nitrate, the conductive salt is calcium pyrophosphate, the corrosion inhibitor is 1-propyl-3-methylimidazolium chloride, and the first complexing agent is mannitol , the second complexing agent is triethanolamine, and the buffering agent is calcium acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com