Glass stripping agent and glass stripping process

A glass and stripping technology, applied in the field of glass stripping agent and glass stripping process, can solve the problems of great harm to operators and the environment, affecting product quality, volatile strong alkali stripping solution, etc. Less harm, good de-plating effect and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

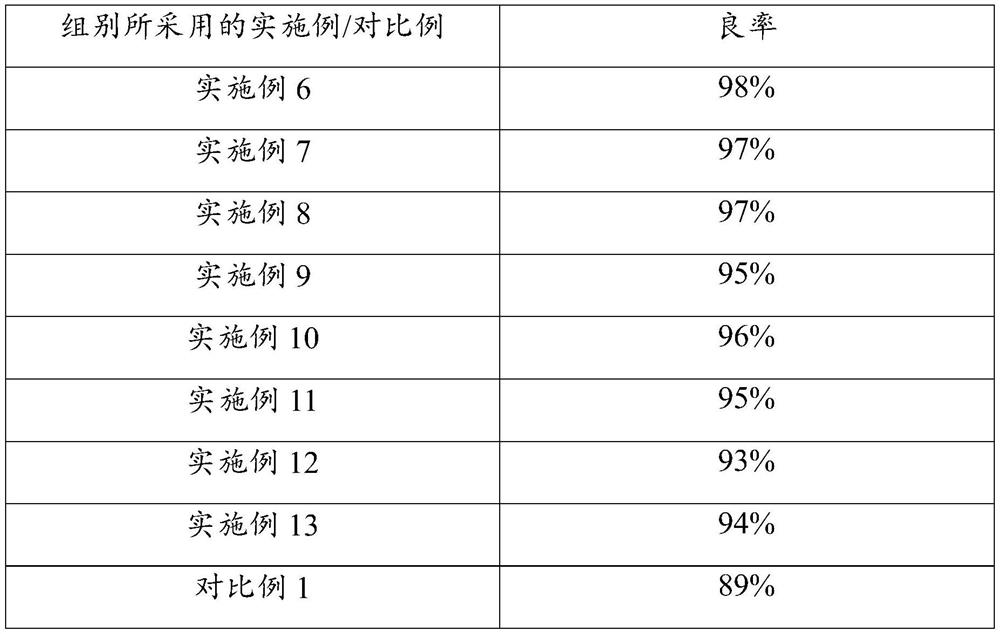

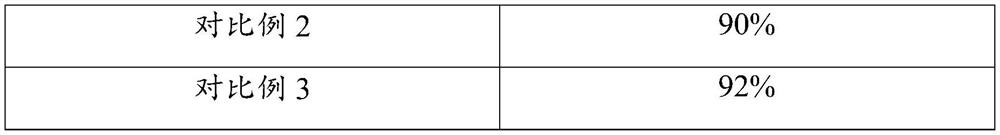

Examples

Embodiment 1

[0108] A glass stripping agent comprises the following components according to mass percentage: 2% potassium hydroxide; 1.5% sodium carbonate; 5% triethanolamine; 0.5% alkanolamide phosphate ester 6503; the rest is water.

Embodiment 2

[0110] A glass stripping agent comprises the following components in mass percentage: 1% of potassium hydroxide; 5% of sodium carbonate; 3% of monoethanolamine; 0.8% of alkanolamide phosphate 6503; and the rest is water.

Embodiment 3

[0112] A glass stripping agent comprises the following components by mass percentage: 3% of potassium hydroxide; 1% of sodium bicarbonate; 10% of triethanolamine; 0.2% of alkanolamide phosphate ester 6503; and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com