Preparation method for ultraviolet-proof dyeing cloth

An anti-ultraviolet and anti-shrinkage finishing technology, which is applied in the field of preparation of anti-ultraviolet printed and dyed fabrics, can solve the problems of sparse warp and weft density of summer clothing materials and contradictions in anti-ultraviolet effects, and achieve the purpose of overcoming poor comfort, improving the ability of anti-ultraviolet, and enhancing The effect of taking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the present invention are clearly and completely described below in conjunction with the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

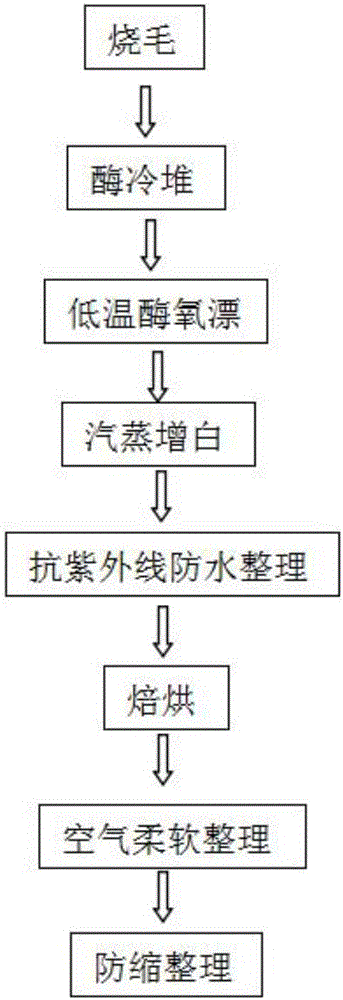

[0028] A preparation method for UV-resistant printing and dyeing cloth, comprising the following steps:

[0029] Step 1: Singeing the hemp fabric at the burner port of the singeing machine for 2 forward and 2 reverse singes, and extinguishing the fire with steam;

[0030] Step 2: roll the hemp fabric rolling working solution A at room temperature of 25°C and stack it for 20-25 hours. The working solution A contains: 10g / L of compound desizing enzyme and 2g / L of penetrating agent;

[0031] Step 3: Wash the linen fabric at 85-90°C for 2-3 grids, roll the working solution B, and steam for 2-3 minutes. The temperature of the steamer is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com