Integrated pile cap forming device and construction method

A former and pile cap technology, which is applied in sheet pile walls, earthwork drilling, foundation structure engineering, etc., can solve the problem that the construction quality of pile caps cannot be effectively guaranteed, the construction period of bored piles is affected, and the operation of construction personnel is not standardized. To achieve the effect of mechanized construction of pile caps, easy control of the construction process, and flexible operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

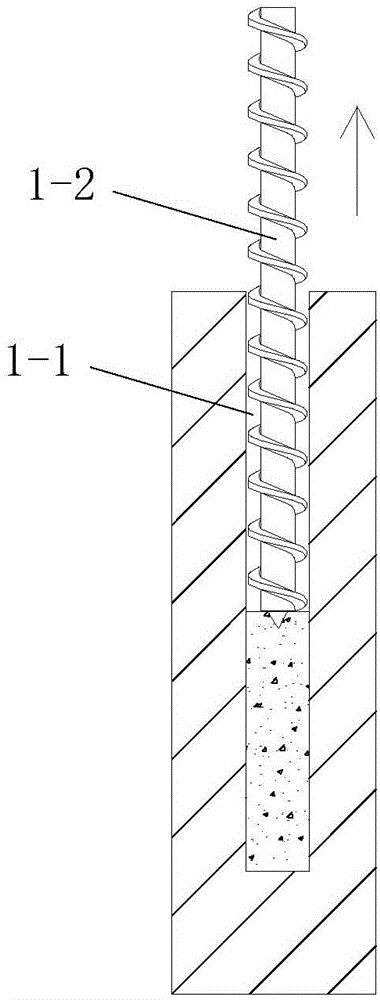

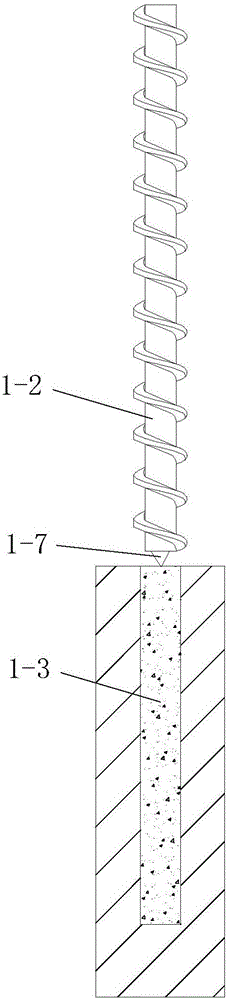

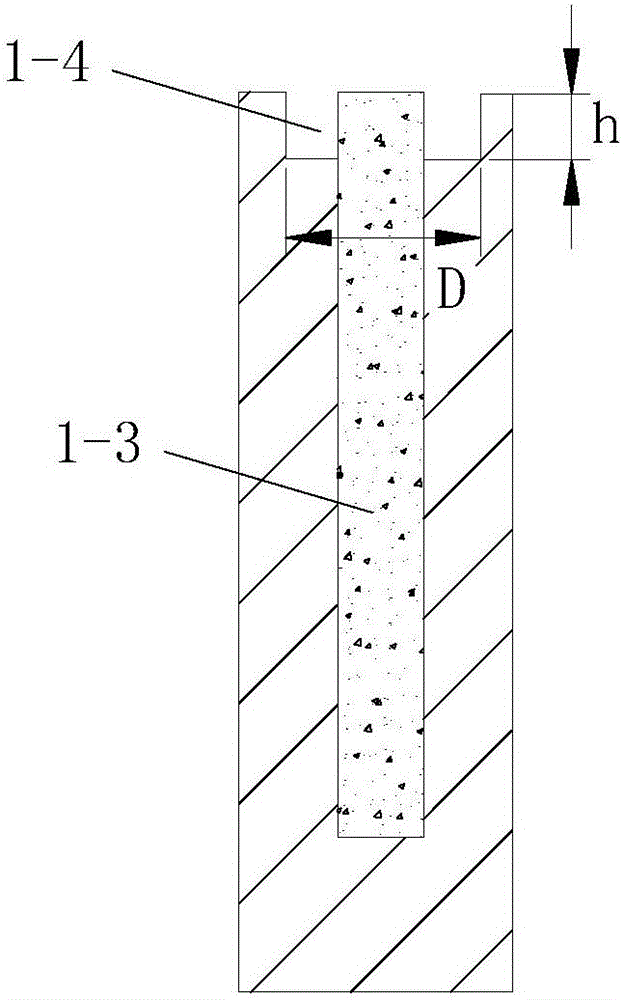

[0055] like figure 1 , figure 2 The shown integrated pile cap former includes a bracket 6, a pile cap forming drill bit installed below the bracket 6, a rotary drive device that drives the pile cap forming drill bit to continuously rotate, and drives the bracket 6 along the pile cap forming drill bit. The central axis of the lifting device moves up and down, and the support 6 is installed on the lifting device; the pile cap forming drill bit is cylindrical and its height is greater than h, and the outer diameter of the pile cap forming drill bit is D, wherein D is the diameter of the pile cap 1-5 to be constructed, h is the height of the pile cap 1-5, and the pile cap 1-5 is a cylindrical pile cap; the pile cap forming drill bit includes a hollow sleeve 2-1 and is composed of The spiral blade 2-2 arranged on the outer wall of the hollow sleeve 2-1 from top to bottom, the hollow sleeve 2-1 is installed on the bracket 6, and the hollow sleeve 2-1 is connected with the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com