Boiler top pasty coal slime inlet structure of circulating fluidized bed boiler

A technology of circulating fluidized bed and coal slime, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, lighting and heating equipment, etc. Reduced utilization rate and other issues, to achieve the effect of simple structure, uniform drop distribution, and less waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

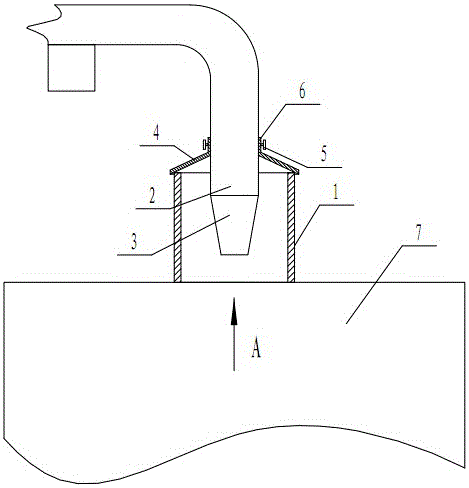

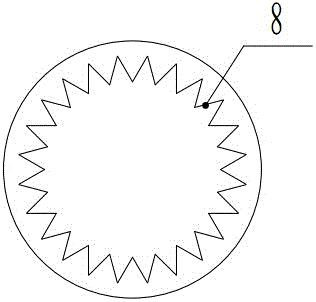

[0016] Embodiment 1: as Figure 1-Figure 2 As shown, a circulating fluidized bed boiler furnace top paste coal slime inlet structure, including the top of the furnace body 7 is provided with a furnace top hole casing 1 and a coal slime inlet insert 2, and the coal slime inlet insert 2 is inserted into the furnace In the top opening casing 1, its end is arranged as a conical part 3 that shrinks downward; the taper of the conical part 3 is 15-20°, and its length is 2-3 of the outer diameter of the coal slime inlet intubation pipe 2. times, through the cone portion of this size, it is beneficial to form the best lump of coal slime, which is more conducive to the combustion in the combustion chamber. The inner side of the lower end of the cone portion 3 is provided with a horizontally directed annular tooth-shaped structure 8, through which the ring-shaped tooth-shaped structure The coal slime group formed at the exit of the ravine is beneficial to drying and burning.

[0017] Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com