Capillary tube wall face heat exchanger applied in subway tunnel

A technology of capillary network and heat exchange system, which is applied to geothermal collectors, geothermal energy, household heating, etc., to achieve the effect of small footprint and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

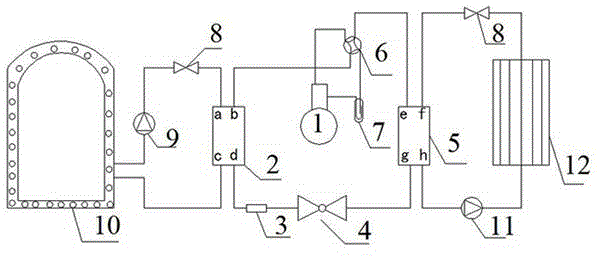

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] A capillary network heat pump air conditioning system applied to heat recovery from industrial wastewater includes a capillary network system for directly extracting heat from industrial wastewater, a water source heat pump system, and a user end system. The capillary wall heat exchanger heat pump system in the subway tunnel consists of a water circulation system. heat exchanger. The cycle period composed of the heat pump unit and the control system generally includes 3 necessary loops

[0013] 1) The refrigerant loop of the heat pump unit is a closed pressurized loop that transfers heat from one place to another. In the evaporation link of the loop, the compressor drives the refrigerant to circulate in the loop.

[0014] 2) Capillary front loop, a closed pressurized loop of water between the capillary front and the condenser. In winter, the unit absorbs hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com