Method for no-reference quantitative inspection of panel thinning defect based on Lamb wave

A flat-panel, defect-free technology that is used in processing the response signals of detection, using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

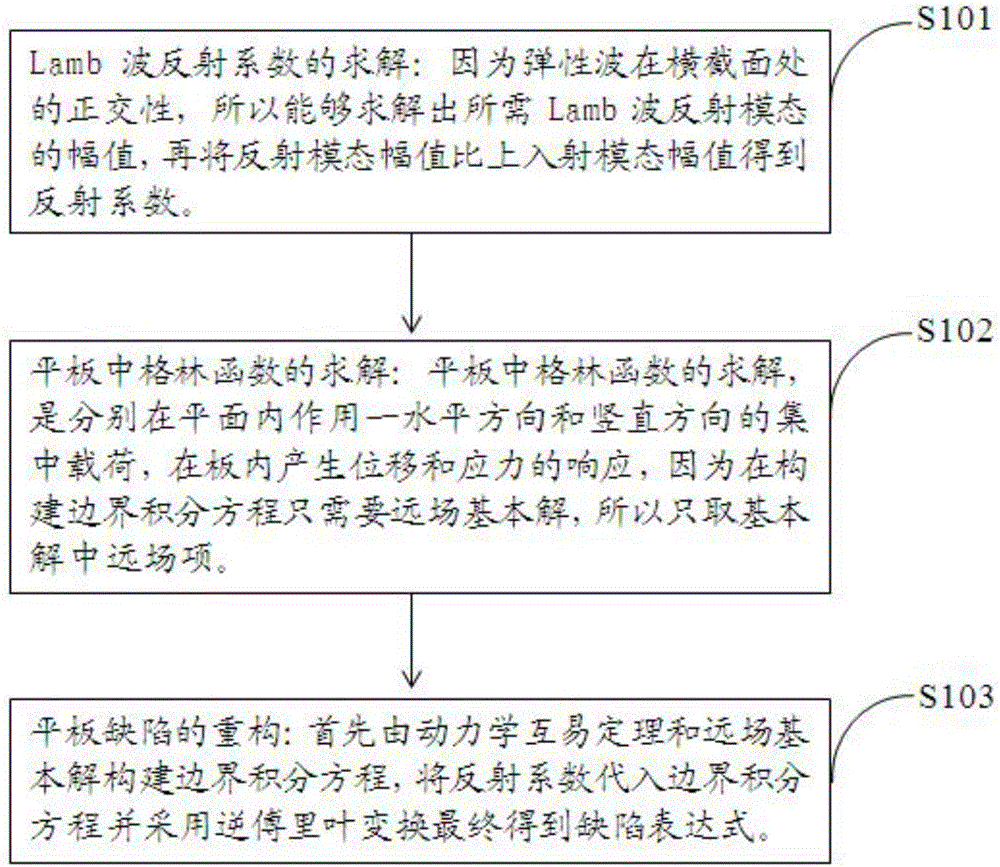

[0201] 1. Carry out modal separation on the total field, and solve the reflection coefficient of the required Lamb wave mode:

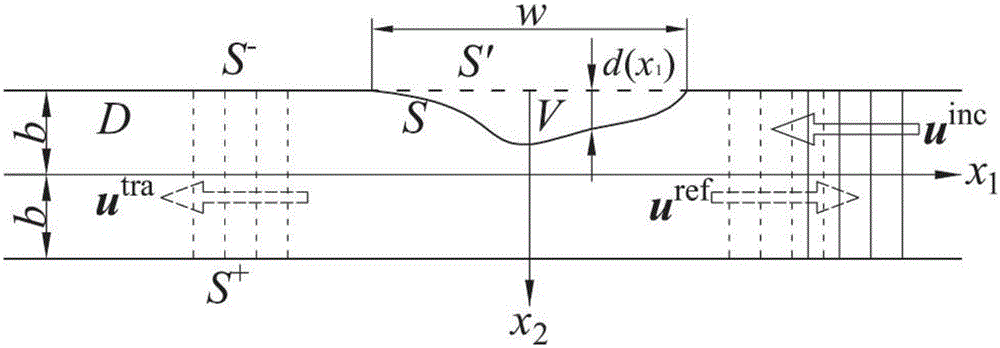

[0202] figure 2 A flat plate with thinning defects is shown, w is the width of the defect surface, b is the half thickness of the plate, S - , S + , S and S′ are respectively the boundary of the non-defective plate, the lower boundary of the non-defective plate, the defect boundary of the plate and the virtual boundary of the defect surface. The defect range V is surrounded by the boundaries S and S′, d(x 1 ) is the defect expression to be sought, and the abscissa x 1 at half-thickness figure 2 Shown, the ordinate x 2 The direction is downward, and the incident wave is along the x 1 Negative direction, interacting with defects to generate reflected wave u ref and the transmitted wave u tra . According to the orthogonality of different modes of the wave field, any two modes of the Lamb wave in the plate are taken as and The cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com