Impedance calibration and compensation method of ATE (automatic test equipment) measuring circuit

A technology for measuring circuit and impedance calibration, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of affecting test results, misjudgment of test results, large error voltage drop, etc., to achieve accurate test results and reduce test errors , the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

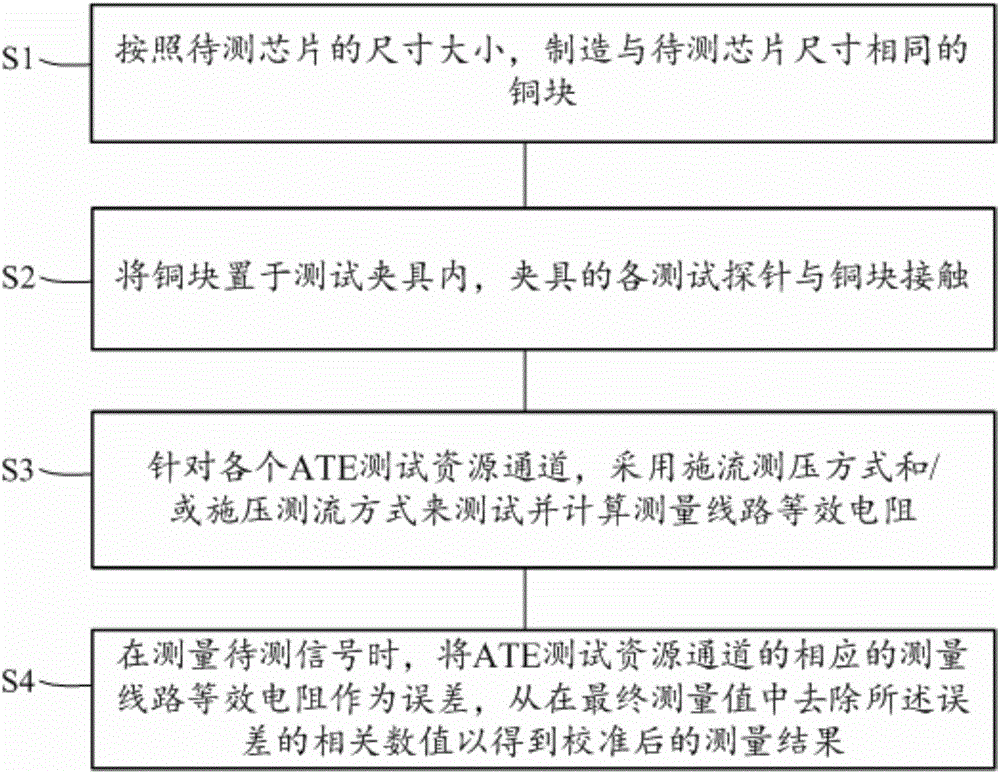

[0022] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

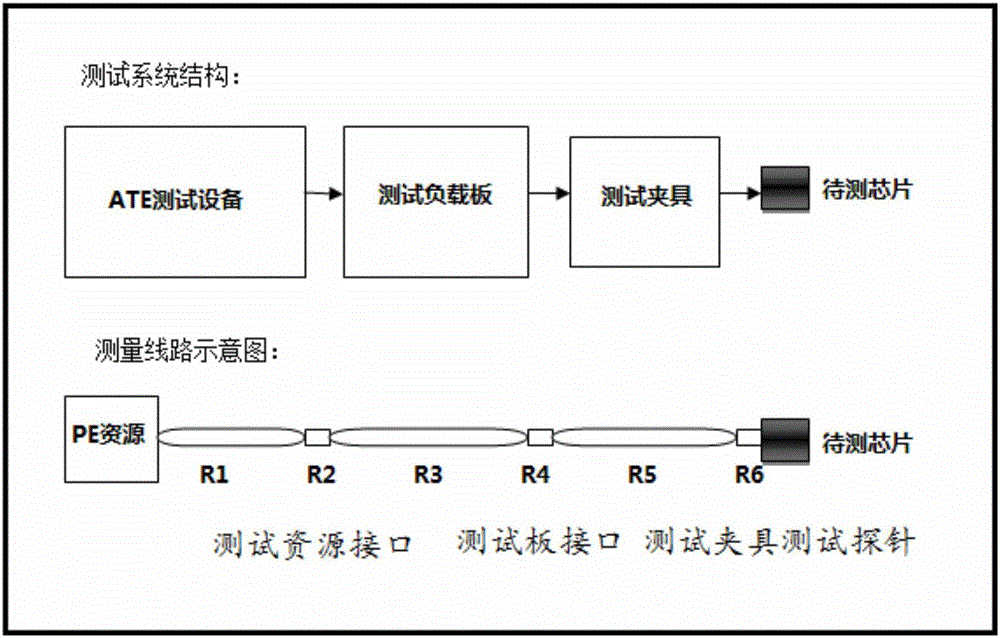

[0023] figure 1 A schematic diagram of the equivalent resistance of the ATE measurement line is schematically shown. Such as figure 1 As shown, in the ATE measurement circuit, the test signal is output from the ATE internal resources, and there is a resistance R1 in the signal channel of the test resource board itself; there is a contact resistance R2 in the connection between the ATE resource interface and the test load board; There is an equivalent resistance R3; there is a contact resistance R4 connected to the test fixture on the test load board, and there is a resistance R5 on the test probe (pogo pin) of the test fixture itself; there is contact between the test fixture test probe (pogo pin) and the chip The impedance R6, the sum of all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com