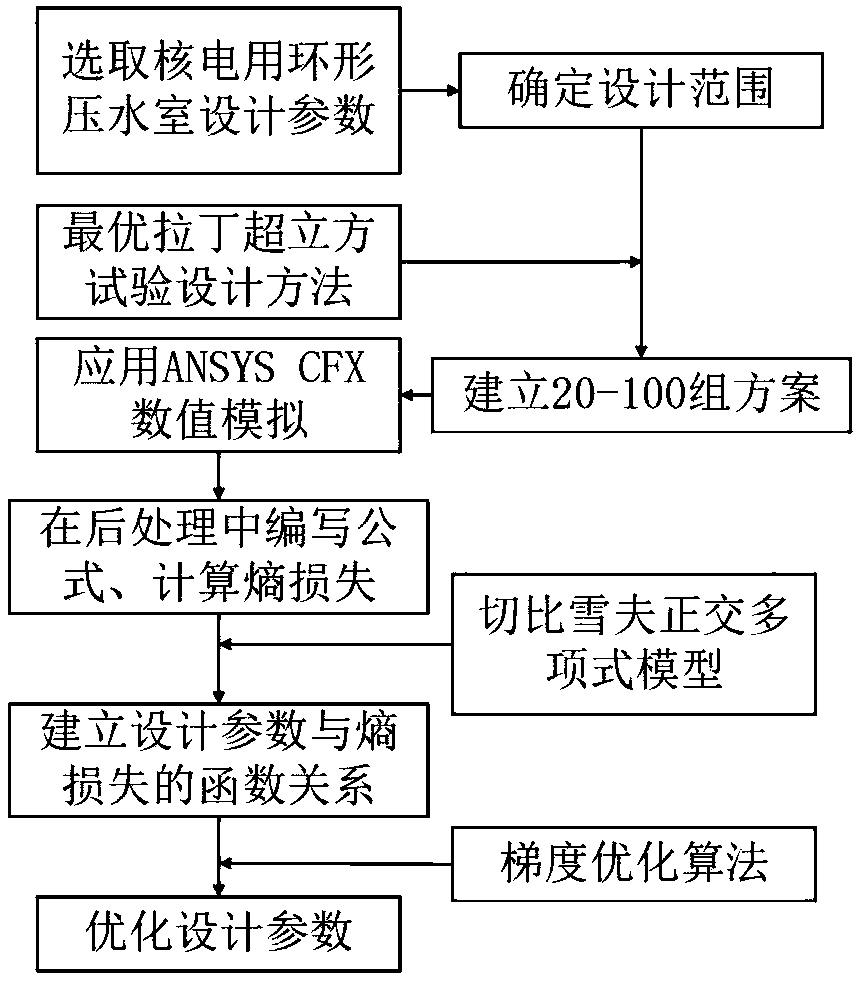

A hydraulic optimization design method for nuclear power pump annular pressurized water chamber based on entropy production analysis

A ring-shaped pressurized water chamber and hydraulic optimization technology, which is applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as difficult quantitative determination of design parameters, and achieve the effect of improving hydraulic efficiency and ensuring operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

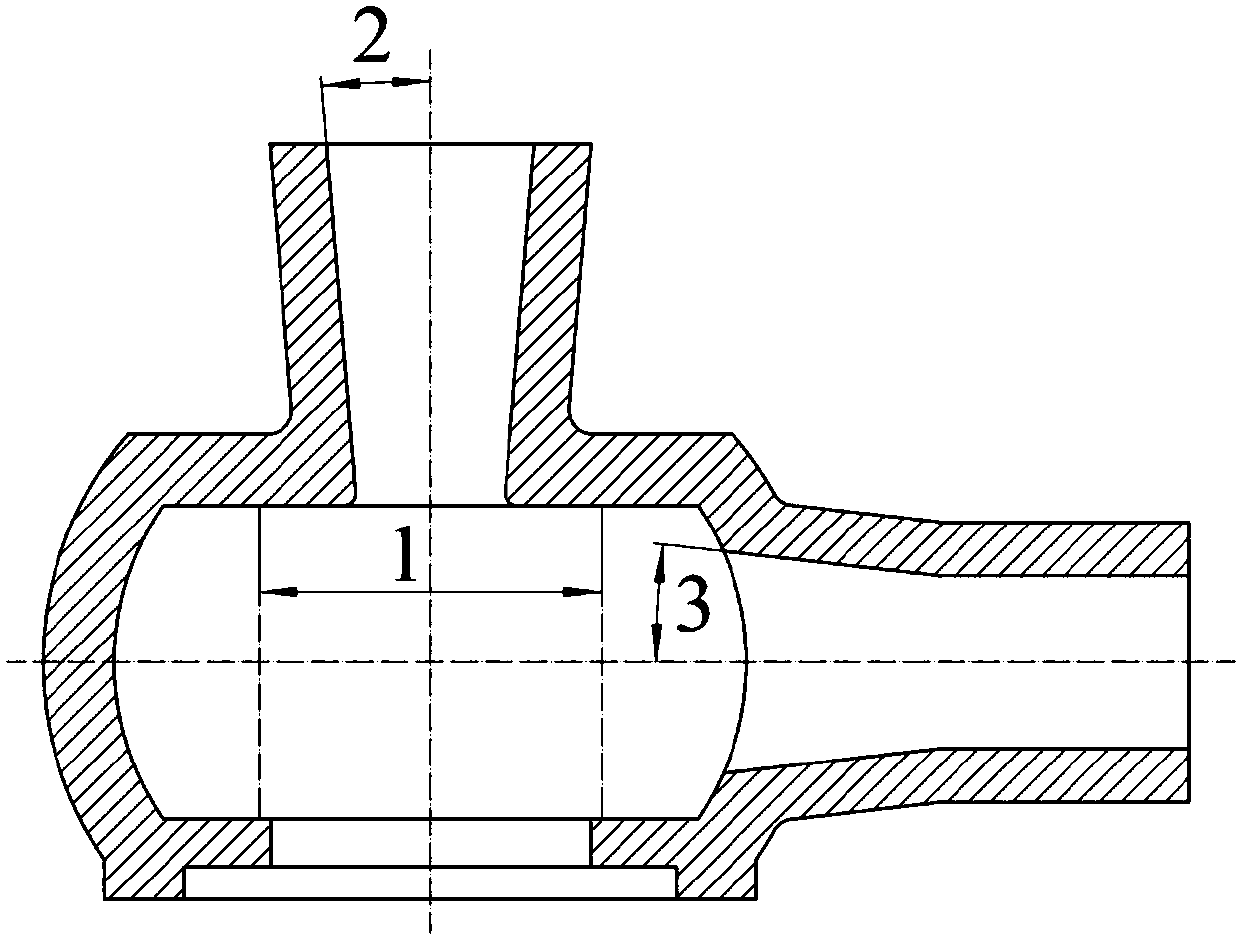

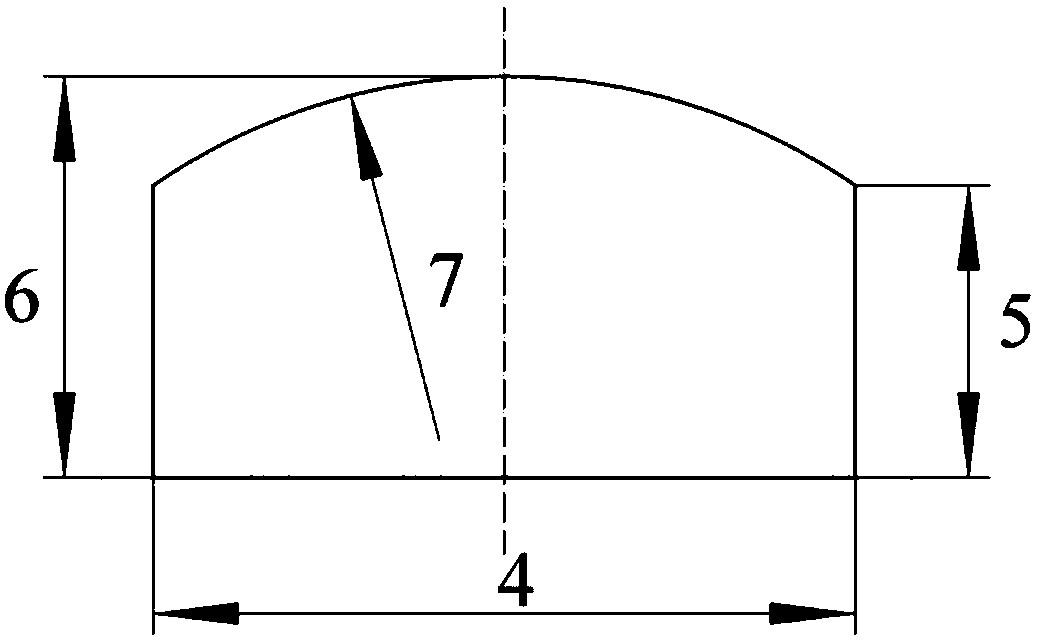

[0069] Embodiment: Taking a certain type of nuclear power pump as an example, the flow rate of the pump is Q=21642m 3 / h, head H=111.3m, impeller outlet width b 2 =200mm, impeller outlet diameter D 2 =800mm. In this implementation case, only the diameter 1 of the base circle of the pressurized water chamber is selected as D 5 , the shrinkage angle 2 of the inlet section is α, the divergence angle 3 of the outlet section is β, and the inlet width 4 of the pressurized water chamber is b 5 As design variables, the design ranges are [1120mm, 1600mm], [0°, 20°], [5°, 30°], [260mm, 800mm], and the height 5 of the straight section of the pressurized water chamber flow section is h= 373mm, the height of the flow section of the pressurized water chamber 6 is H 1 =600mm, the radius 7 of the circular arc section of the pressurized water chamber flow section is r=830mm. Using the optimal Latin hypercube design method, the following 20 groups of schemes are designed, as shown in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com