An off-resonance type wheel-type generator based on a cantilever beam piezoelectric vibrator

A technology of piezoelectric vibrator and cantilever beam, which is applied in the field of new energy and power generation, can solve the problems of low blade speed, power supply by wires, weak power generation capacity, etc., and achieve the effect of effective frequency bandwidth, high reliability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

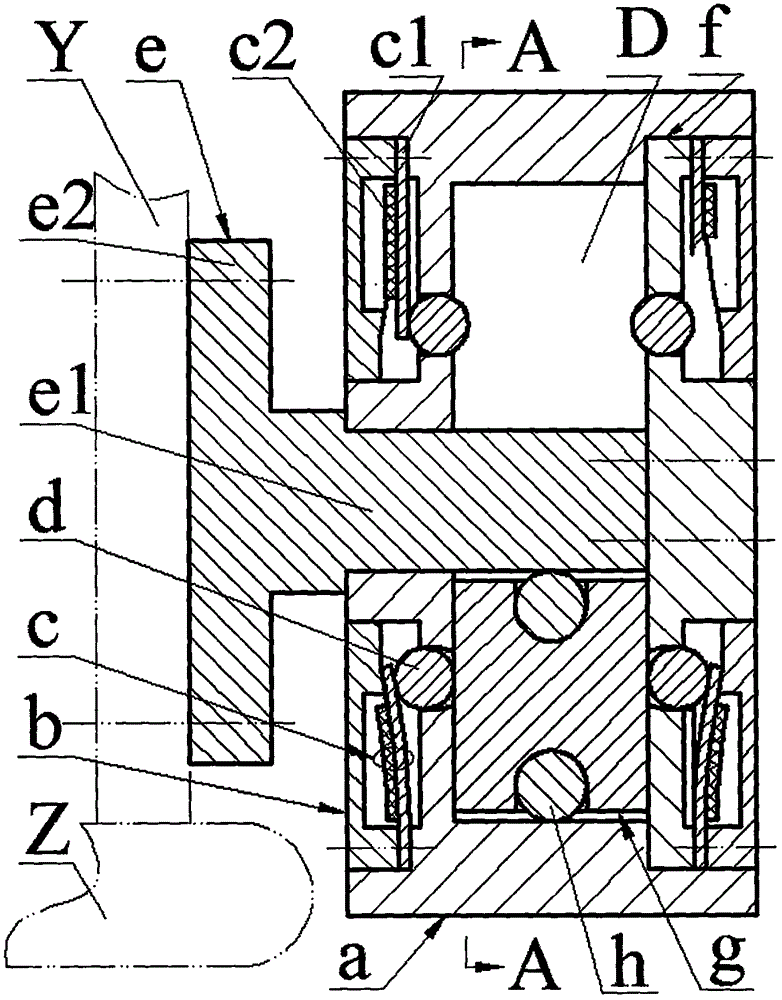

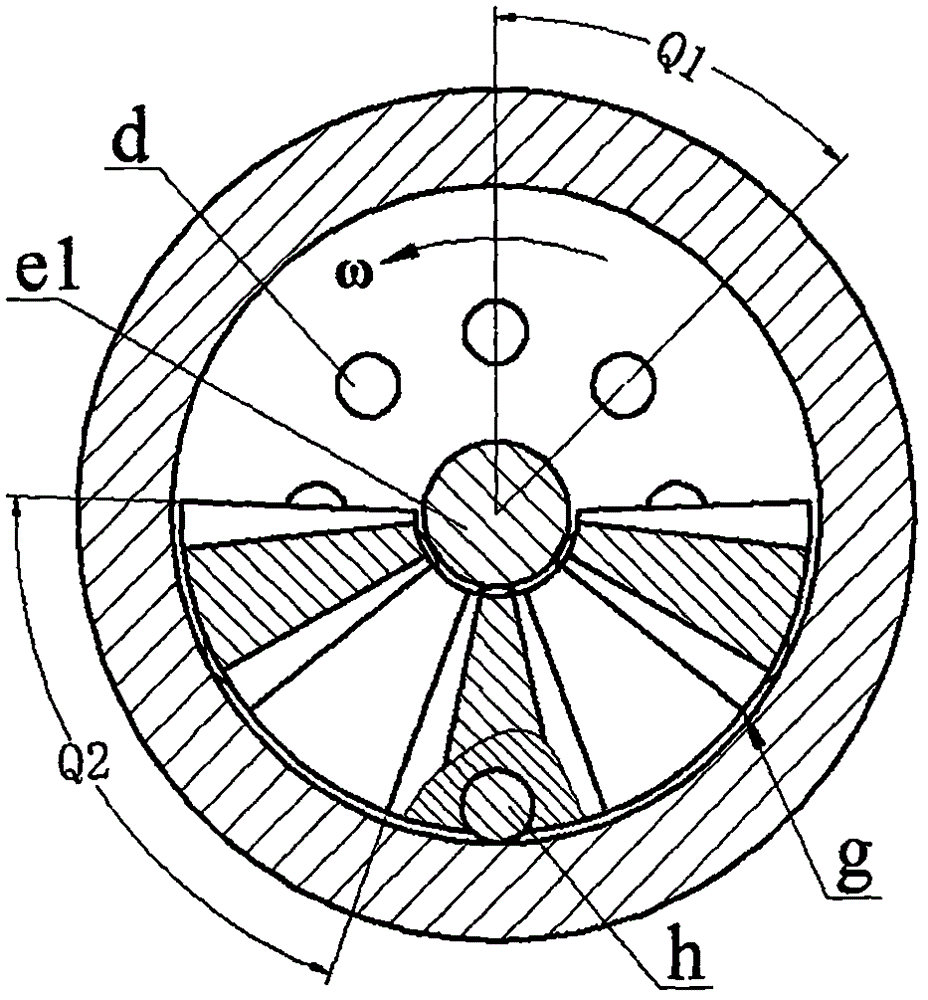

[0017] One side of the turntable a is provided with a stepped turntable ring cavity a1 and a central hole a4, and the other side is provided with a slideway sink cavity a3, the slideway sink cavity a3 communicates with the center hole a4, and connects with the turntable ring cavity through the turntable guide hole a2 a1 is connected; the center hole a4 of the turntable a is covered with the cantilever shaft e1 of the connector e, the side of the turntable a with the slideway sink cavity a3 is equipped with the side plate f through the screw, and the side plate f is connected with the cantilever shaft e1 through the screw The side plate ring cavity f1 and the side plate guide hole f2 are provided on the side plate f; the exit of the turntable guide hole a2 and the side plate guide hole f2 close to the slideway sink cavity a3 is a spherical surface, and the turntable guide hole a2 and the side Extrusion balls d are installed in the guide hole f2 of the plate; the metal base c1 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com