High-frequency SAW (Surface Acoustic Wave) device based on Si substrate and manufacturing method thereof

A high-frequency and device technology, applied in the field of Si-based high-frequency SAW devices and their preparation, can solve the problems of low Si phase velocity and affect the center frequency of multi-layer structure SAW devices, and achieve high electromechanical coupling coefficient and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

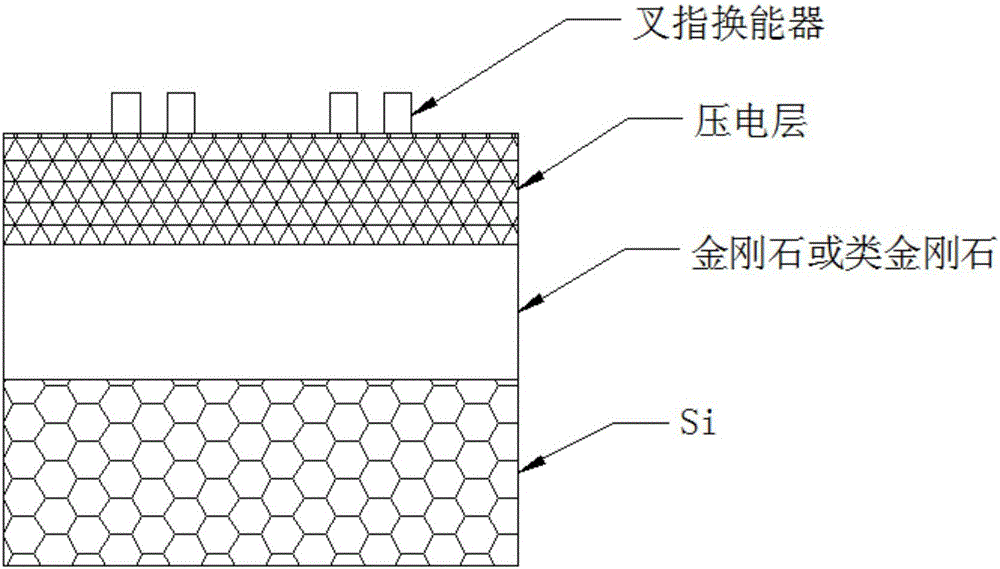

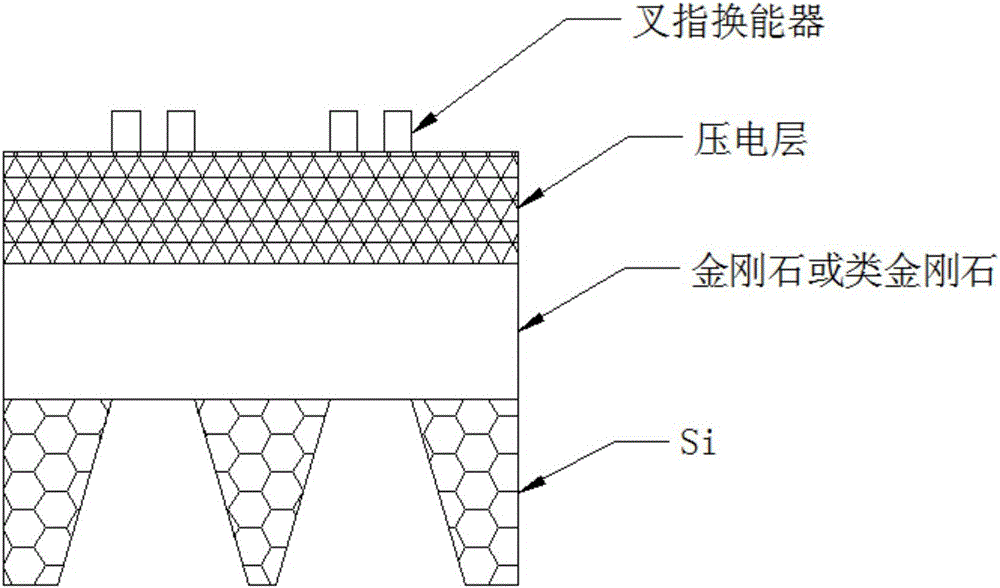

[0022] In order to enable a clear and complete description of the technical solution of the present invention, further description will be given with reference to the accompanying drawings.

[0023] prepared as figure 2 A Si-based high-frequency SAW device is shown.

[0024] Step 1. Using CVD to grow a diamond film with a thickness of 500nm on a Si substrate with a thickness of 2mm, polishing it with CMP to make the roughness 10nm, and then cleaning to obtain a diamond / Si substrate.

[0025] Step 2, using radio frequency magnetron sputtering to deposit a layer of AlN film with a thickness of 200nm on the diamond / Si substrate.

[0026] Step 3. Spin-coat a layer of photoresist on both sides of AlN / diamond / Si with a glue spinner, and make a pattern on the back of Si by photolithography, and soak in 10% KOH for 5 minutes, and make a pattern on the back of Si. Such as figure 2 The number of grooves shown is 2, the side of the trapezoidal cross-section is 0.6mm, the length of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com