Device and method for graded ammonia injection flue gas denitrification

A denitrification and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as difficult implementation, and achieve the effects of easy implementation, weakened influence, and reduced relative deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

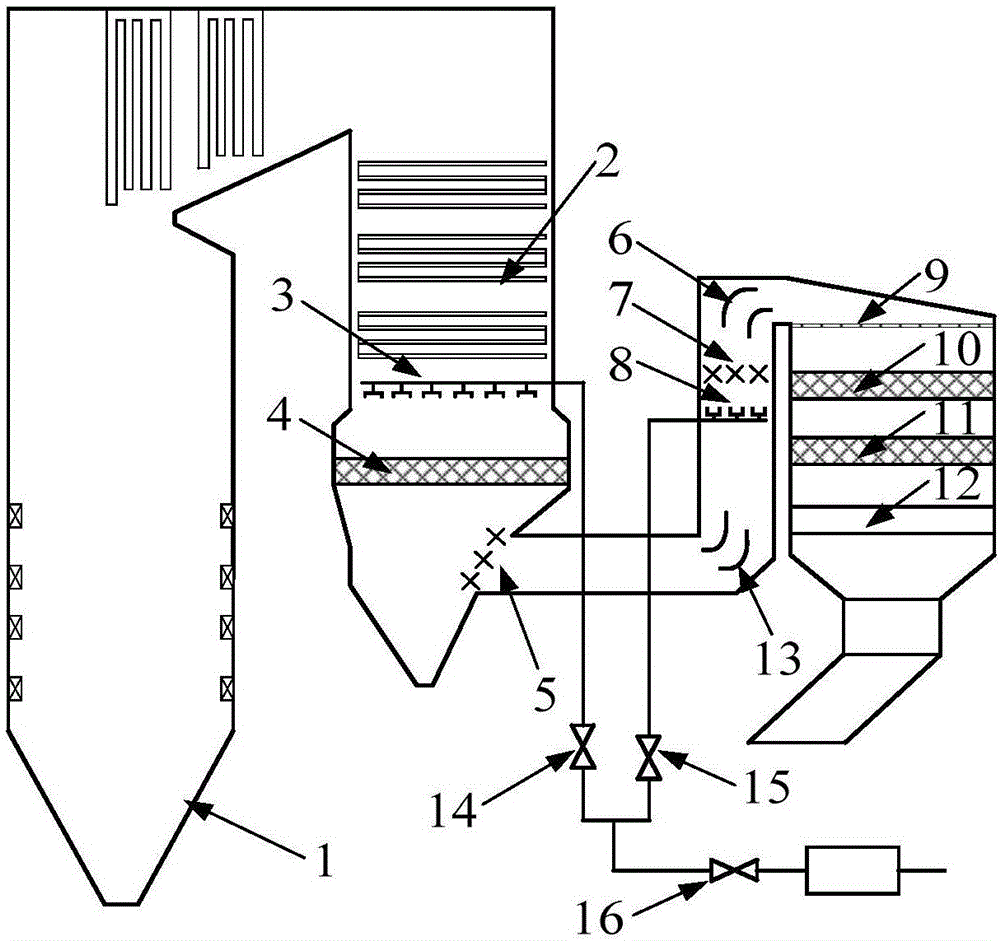

[0038] Embodiment 1: as figure 1 As shown, a graded ammonia injection flue gas denitrification device is connected with the tail flue of the boiler, including: a furnace 1; an economizer 2 located at the tail of the furnace 1; a first-stage ammonia injection grid 3, and a first-stage catalyst layer 4 and the first-stage mixer 5 are installed in the outlet of the economizer 2, the first-stage catalyst layer 4 is placed under the first-stage ammonia injection grid 3, and the first-stage mixer 5 is placed behind the first-stage catalyst layer 4 , which is located at the exit of the economizer 2, the first-stage ammonia injection grille 3 is a linear control type; then it is connected to the SCR lower corner deflector 13, the second-stage ammonia injection grille 8, and the second-stage mixer 7 in sequence and SCR upper corner flue 6, the second-stage mixer 7 is located behind the nozzle of the second-stage ammonia injection grille 8, the second-stage ammonia injection grille 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com