Press dewatering system in paper machine structure for artificial board facing body paper production

A technology for pressing and dewatering, wood-based panels, applied in the paper machine, paper making, pressing parts, etc., can solve the problems of not reaching the expected target, the deviation of the transmission path, the dryness of the base paper, etc. The effect of tightening degree and increasing pressing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

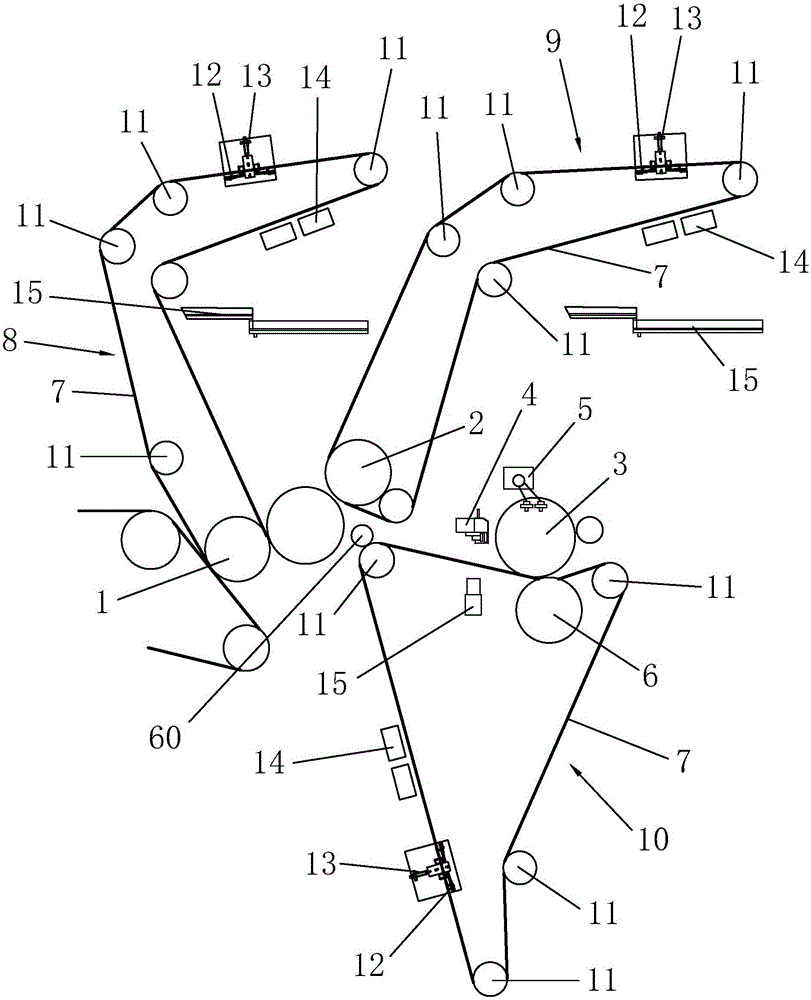

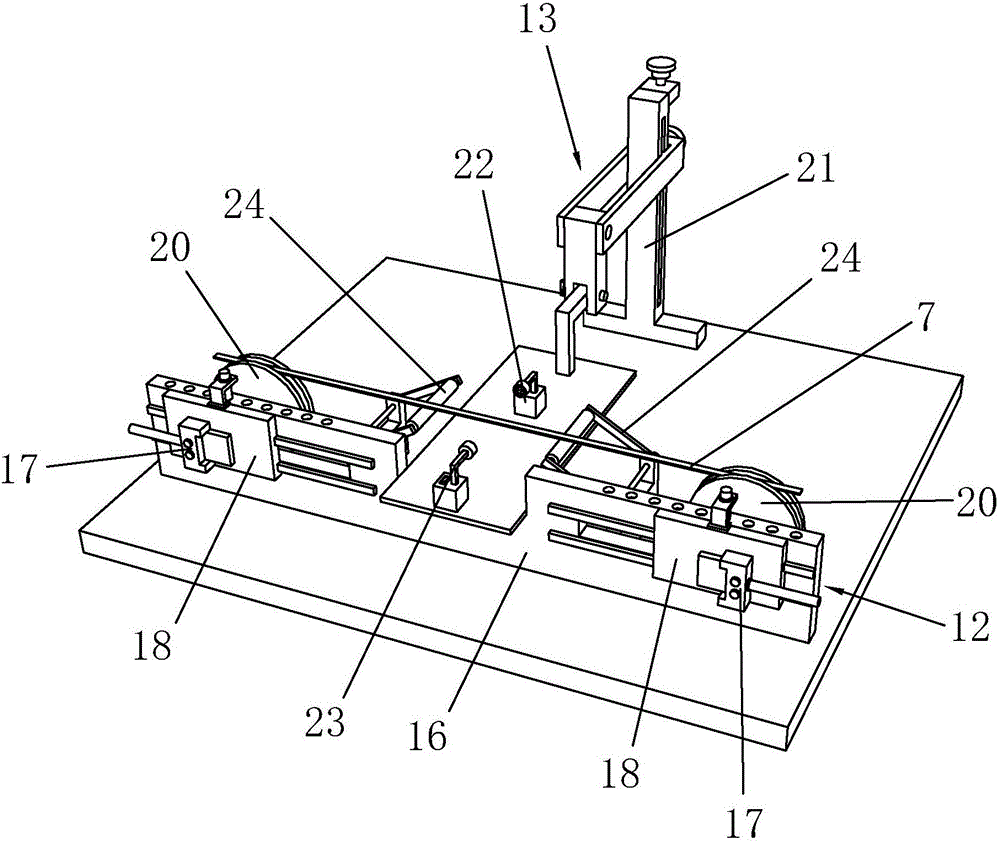

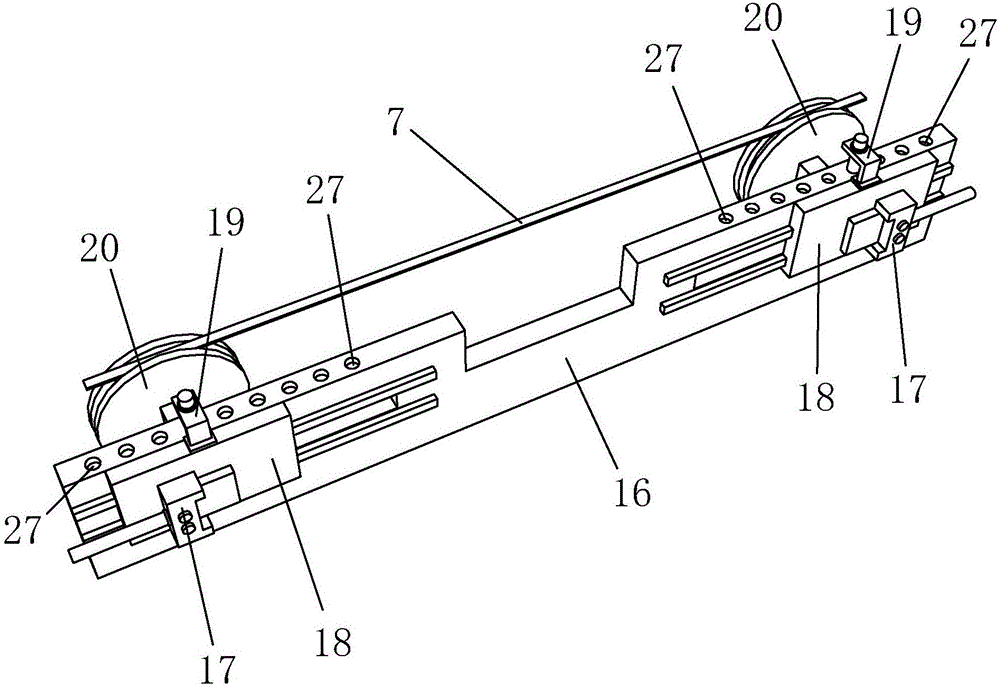

[0032] Such as Figure 1 to Figure 9 Shown is the press dehydration system in the structure of the paper machine for producing wood-based panel facing base paper of the present invention, including a paper guide roll 60, a vacuum suction press roll 1, a vacuum press roll 2, a stone roll 3, double scrapers 4, and a spraying device 5. Blind hole roller 6 and felt cloth 7. A first felt circuit 8 is provided at the vacuum suction press roll 1, a second felt circuit 9 is provided at the vacuum press roll 2, and a third felt circuit 10 is provided at the blind hole roll 6. Guide rollers 11 are driven in the first felt circuit 8 , the second felt circuit 9 and the third felt circuit 10 . The first felt circuit 8 , the second felt circuit 9 and the third felt circuit 10 are all provided with a tensioning device 12 , a correction device 13 , a water suction box 14 and a water receiving tray 15 . The pressurization method of the present invention is all hydraulic pressure, equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com