Environmental protection, energy saving and high efficiency gasification boiler

A gasification boiler, environmental protection and energy saving technology, applied in lighting and heating equipment, combustion equipment, combustion of solid fuel, etc., can solve the problems of poor desulfurization effect, high manufacturing cost, and many attached machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

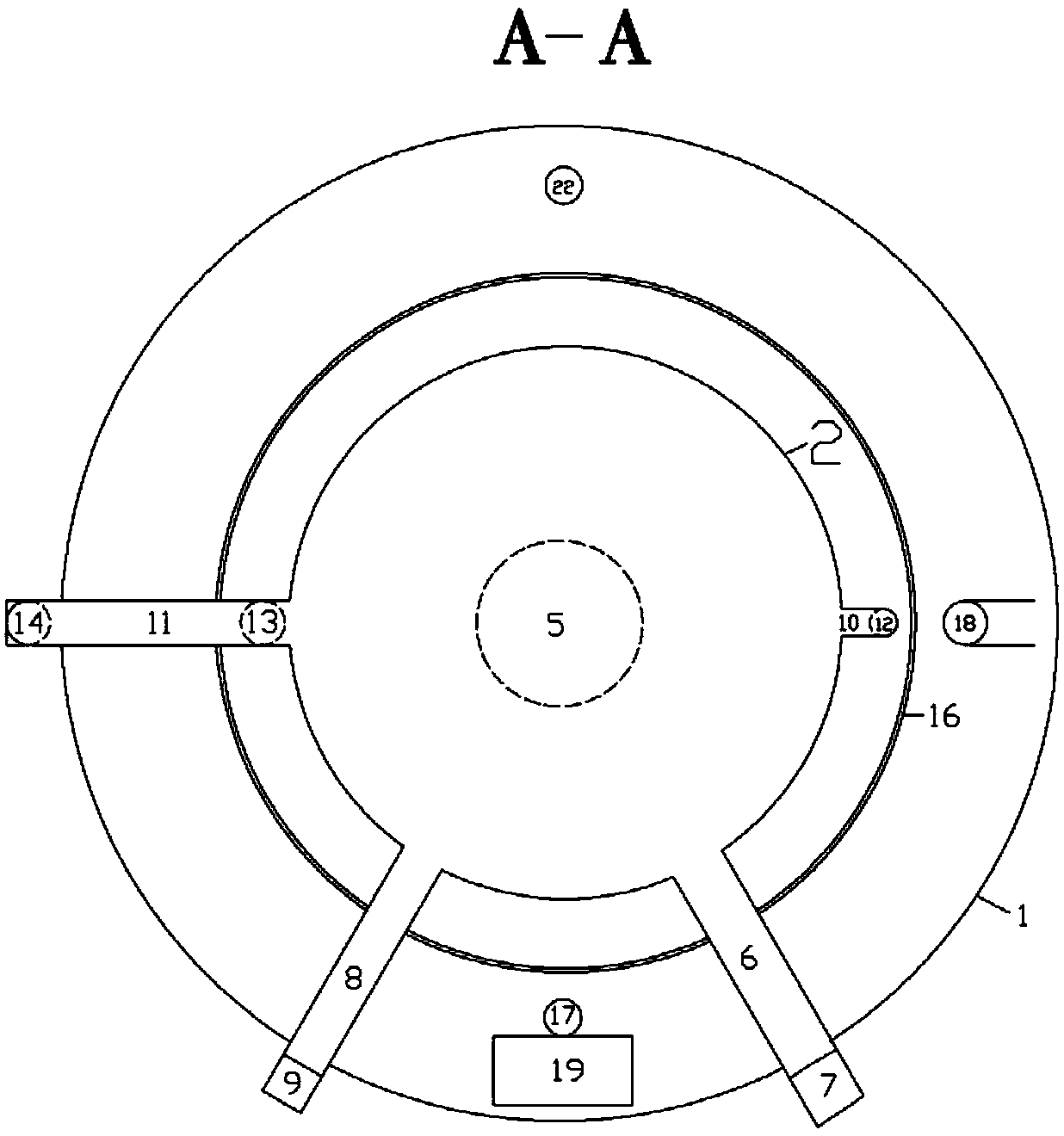

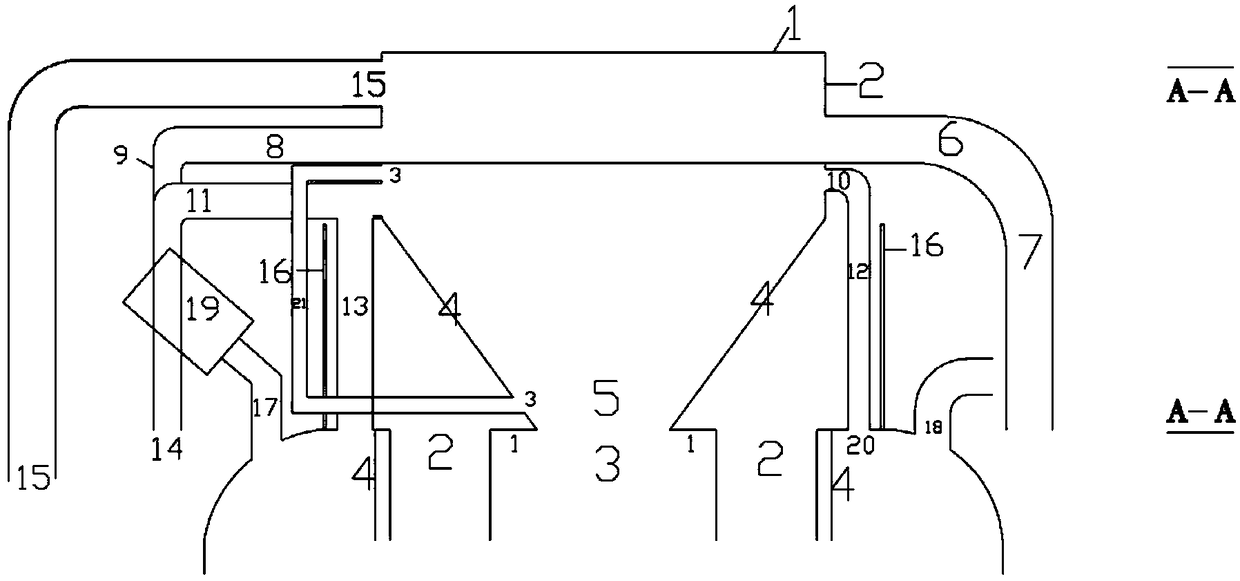

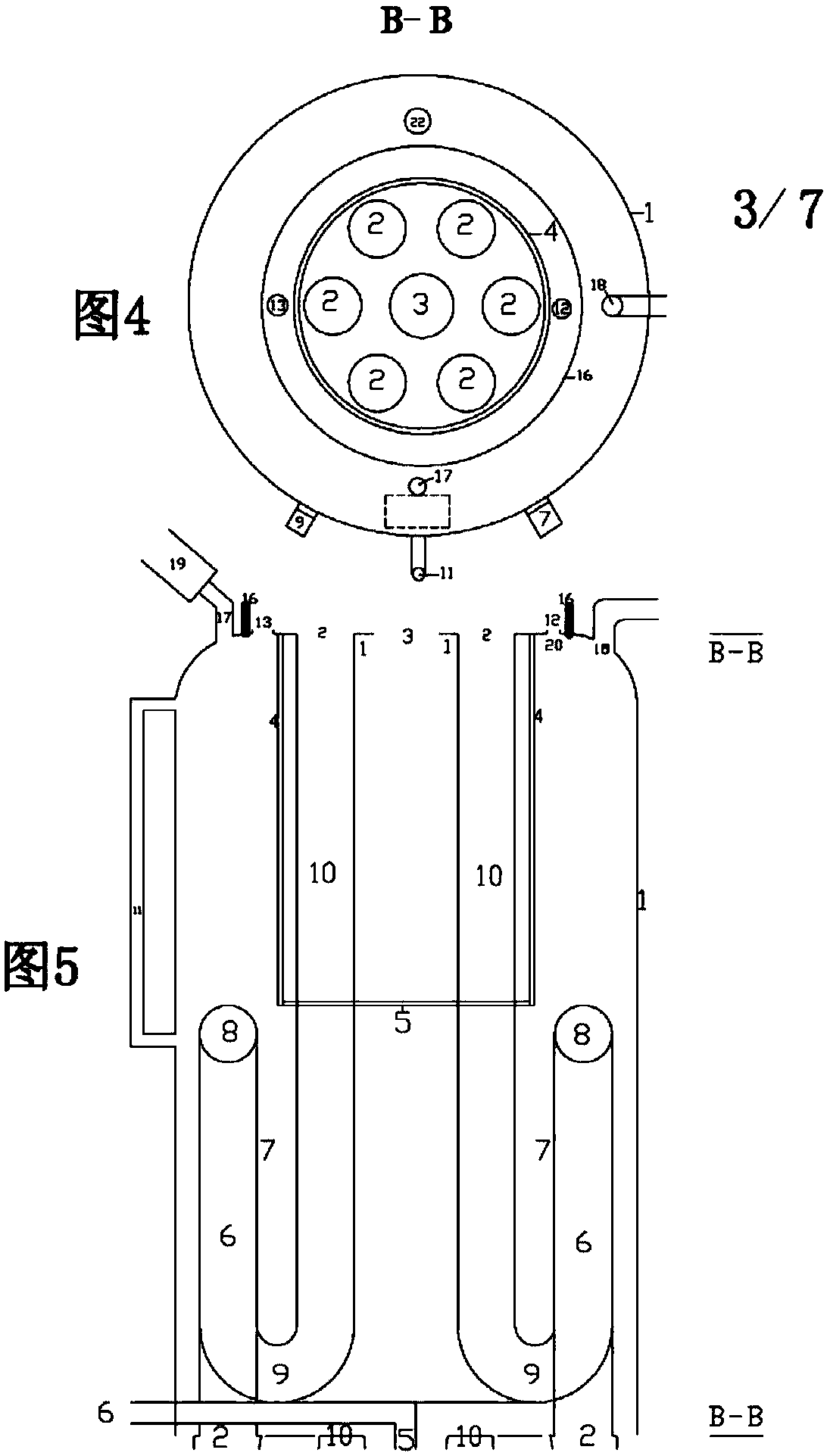

[0064] Specific embodiment one: a kind of environment-friendly energy-saving high-efficiency gasification boiler, the design wind box (1) (2) is installed on the furnace top of A part, is equipped with miniature electric blower and wind is blown into the box by the pipeline (15) of design. The first furnace is designed in part D, the second combustion chamber is designed in part C, and the oxygen supply casing (3) (11) is designed in the interior to ensure that the oxygen supply pipe does not burn out, and the oxygen supply plate (7) (8) is designed to Oxygenation evenly. The feed inlet (4) is designed in the D part of the furnace, and the fuel is put into a furnace at a fixed time, which can be filled at one time for burning for a long time without adding fuel in the middle. Furnace ignition heating element (6) designed by E part burns the fuel in an instant, and a water tank is designed at the furnace bottom of part E of the furnace to achieve dust removal effect, and no fin...

specific Embodiment approach 2

[0065] Embodiment 2: An environment-friendly, energy-saving and high-efficiency gasification boiler, each sub-furnace has 6 curved pipes (3) in the first furnace of part D, and 6 curved pipes (4) in the second combustion chamber of part C.

specific Embodiment approach 3

[0066] Specific embodiment three: a kind of environment-friendly energy-saving high-efficiency gasification boiler, each sub-furnace has 6 self-combustion oxygen supply flat tubes (2) in the D part design, when there is no fan heat supply oxygen, the gas can be burned normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com