A biomass gasification burner

A burner and biomass technology, applied in combustion methods, combustion equipment, solid fuel combustion, etc., can solve problems such as safety accidents, explosions, equipment damage, etc., to reduce smoke, suppress excessive smoke, and avoid backfire The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

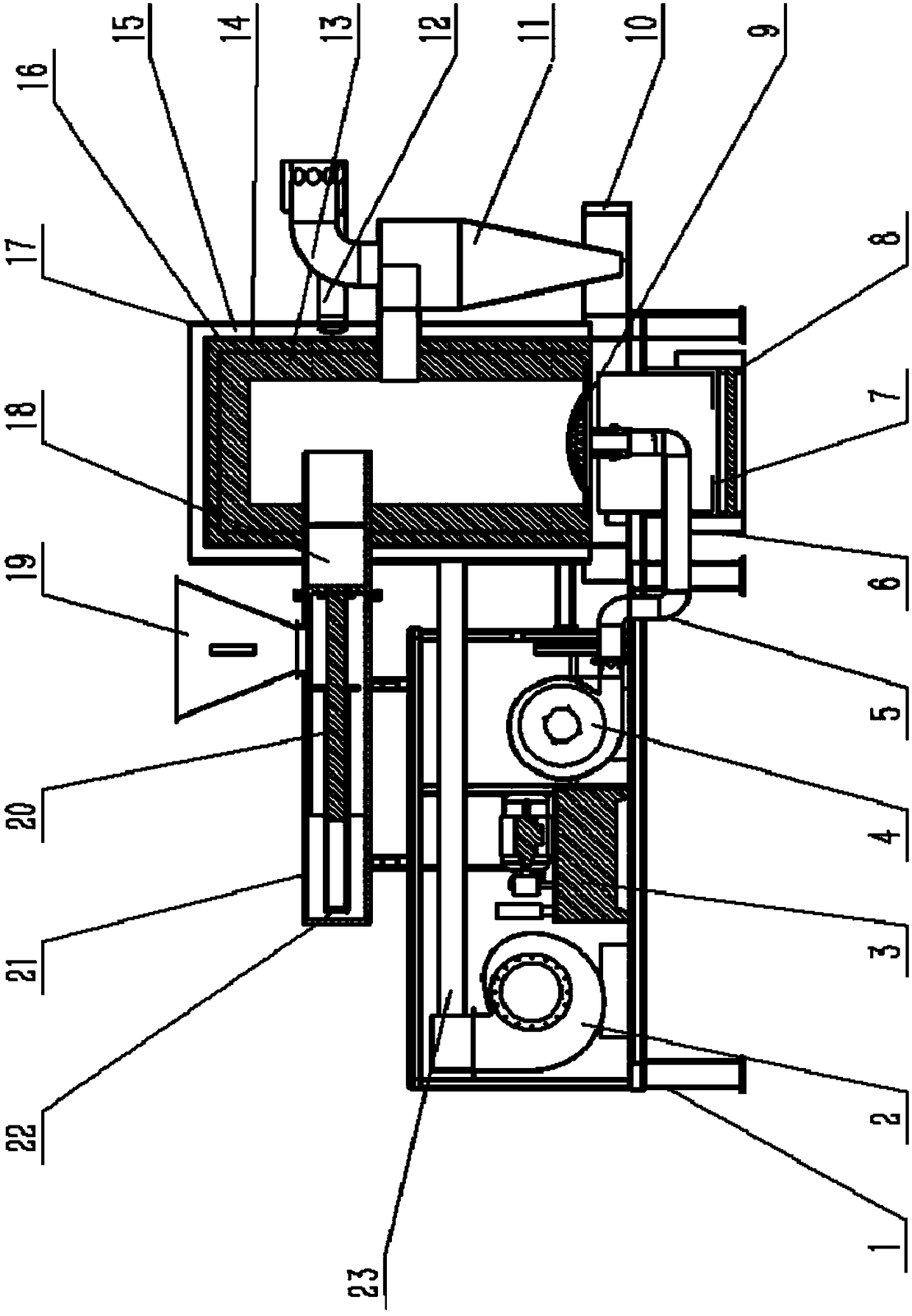

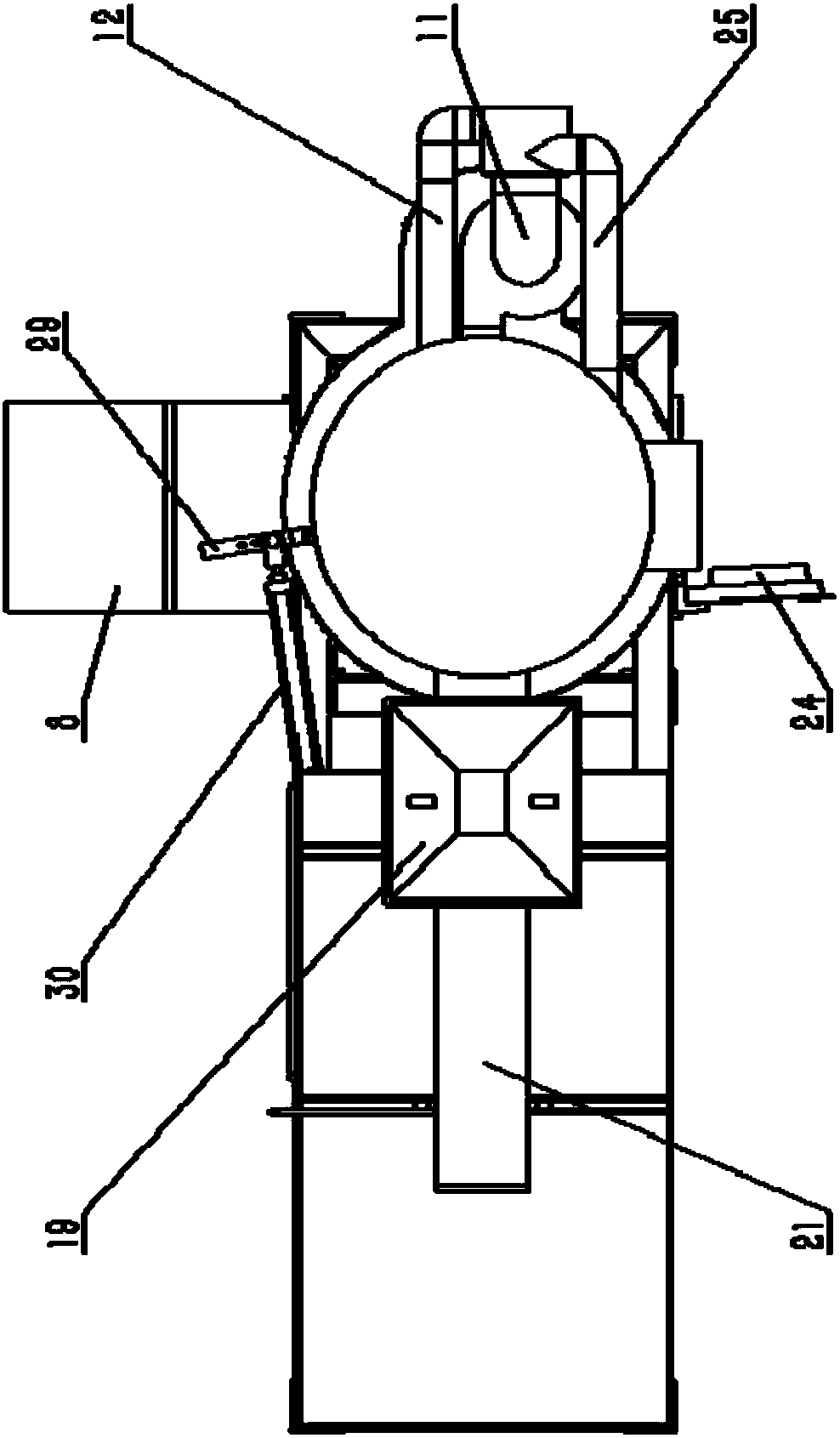

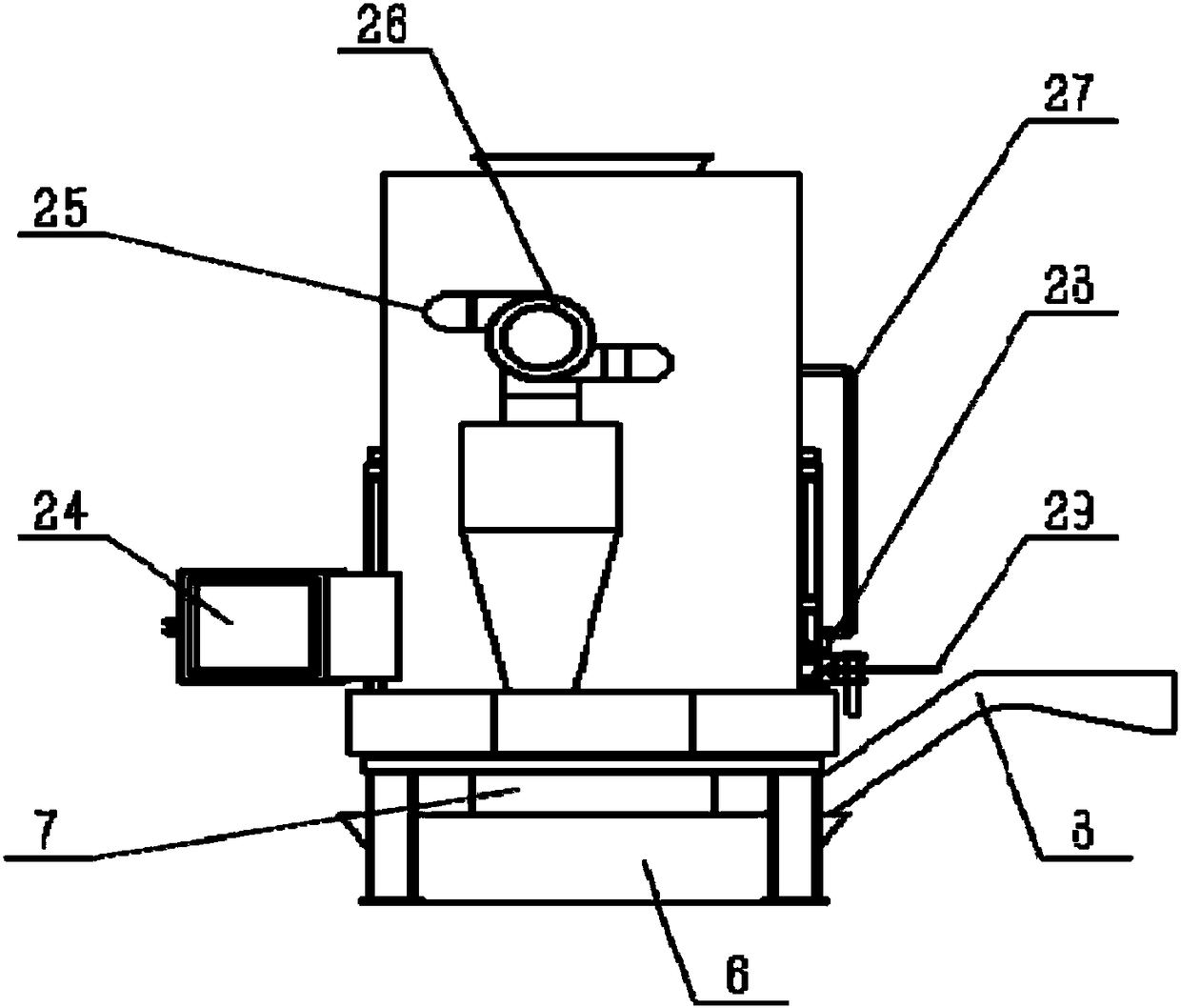

[0037] Such as Figure 1~8 As shown, the present invention includes: a frame 1, a furnace, a hydraulic slider feeding mechanism, a cyclone separator 11, a hydraulic slag and ash cleaning mechanism, a first water tank 6, a second water tank 10, a slag collector 7, and a combustion port 26;

[0038] The furnace includes a refractory layer 13, an insulation layer 14, an inner furnace 16, and a furnace door 24. The refractory layer 13, the insulation layer 14, and the inner furnace 16 are connected from the inside to the outside in sequence, and a furnace door is provided on the lower front side of the furnace. twenty four;

[0039] One end of the hydraulic slider feeding mechanism is fixedly arranged on the frame 1, and the other feeding end extends into the furnace;

[0040] The hydraulic slag and ash removal mechanism is arranged on the lower side of the inside of the furnace;

[0041] The slag collector 7 is cylindrical and the two ends are not sealed. The slag collector 7 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com