A non-azeotropic mixed working fluid solution defrosting freezing regeneration large temperature difference heat pump unit

A non-azeotropic mixing, heat pump unit technology, applied in refrigerators, refrigeration components, compressors, etc., can solve the problems of restricting the application of regeneration devices, achieve zero energy consumption for defrosting, improve regeneration efficiency and speed, and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

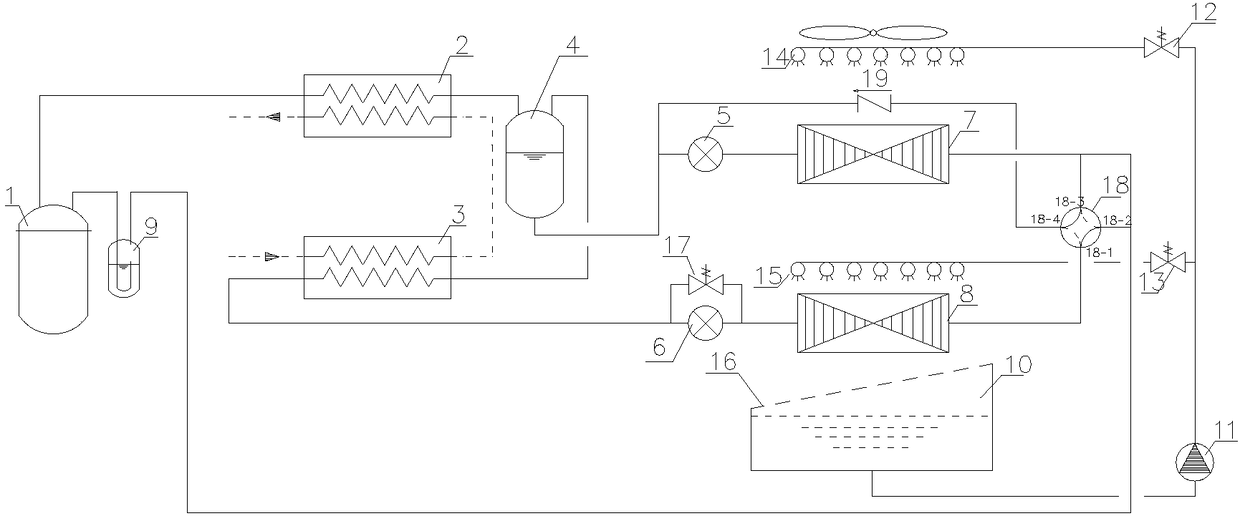

[0025] combine figure 1 The non-azeotropic mixed working fluid solution defrosting and freezing regeneration large temperature difference heat pump unit of the present invention uses the high and low temperature condenser to improve the temperature difference of the heat exchange medium on the secondary side, and uses the low bubble point temperature evaporator as the solution regeneration heat exchanger to remove the heat pump. The frosted dilute solution is frozen for regeneration. The operating modes of the unit are as follows:

[0026] (1) Normal heating operation mode

[0027] The solenoid valve 17 is closed, the 18-3 and 18-4 ports of the four-way reversing valve 18 are connected, and the 18-1 and 18-2 ports are connected. The high-temperature and high-pressure gas at the outlet of compressor 1 first enters the second user-end heat exchanger 2 to condense into gas-liquid two-phase, in which the high-boiling point components are almost completely condensed. The gas-liqui...

Embodiment 2

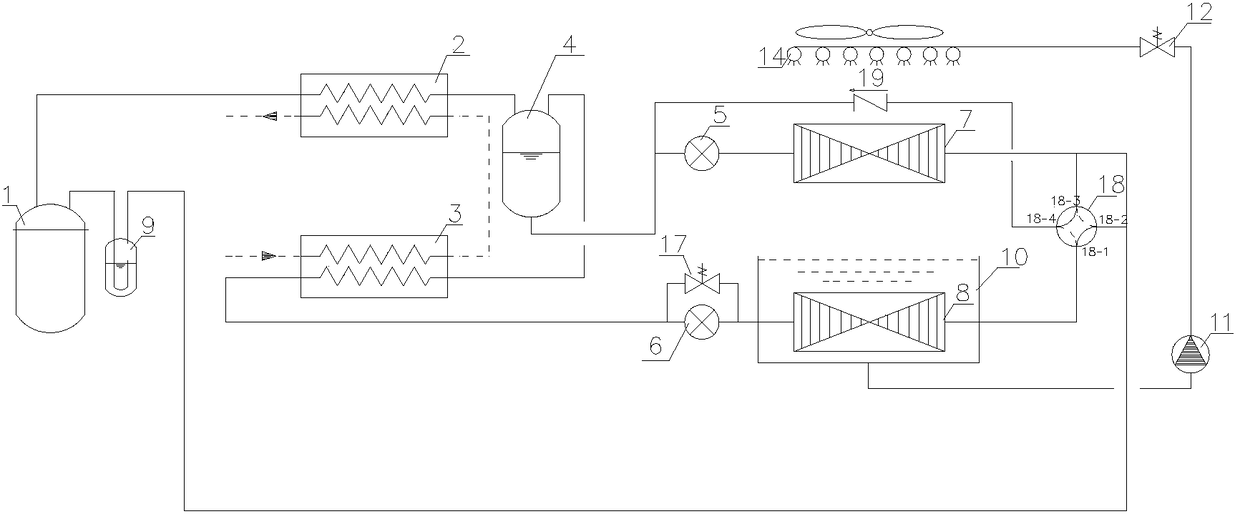

[0035] combine figure 2 The non-azeotropic mixed working fluid solution defrosting and freezing regeneration large temperature difference heat pump unit of the present invention uses the high and low temperature condenser to improve the temperature difference of the heat exchange medium on the secondary side, and uses the low bubble point temperature evaporator as the solution regeneration heat exchanger to remove the heat pump. The frosted dilute solution is frozen for regeneration. The operating modes of the unit are as follows:

[0036] (1) Normal heating operation mode

[0037] The solenoid valve 17 is closed, the 18-3 and 18-4 ports of the four-way reversing valve 18 are connected, and the 18-1 and 18-2 ports are connected. The high-temperature and high-pressure gas at the outlet of the compressor 1 first enters the second user-end heat exchanger 2 and condenses into a gas-liquid two-phase, in which the high-boiling point components are almost completely condensed. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com