Powder drying and conveying system

A conveying system and drying technology, which is applied in the direction of drying solid materials, granular materials, and dry goods, can solve the problems of reduced production efficiency, blockage of air blower, and poor working environment, so as to improve production efficiency, reduce dust loss, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

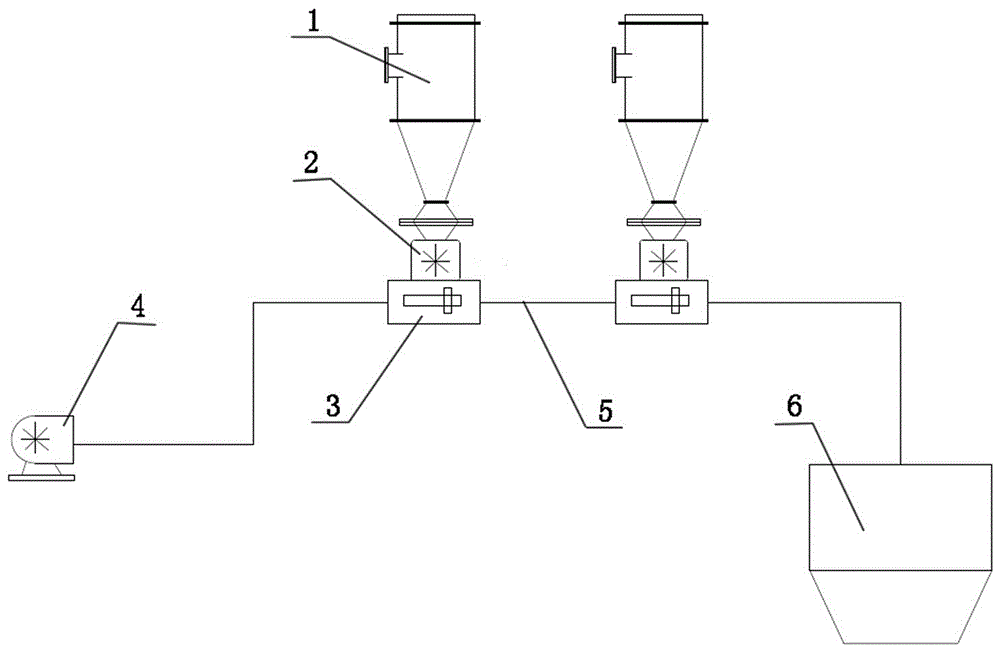

[0008] figure 1 As shown, a powder drying conveying system includes a blower 4, a conveying pipeline 5, a dryer 6, more than one cyclone separator 1, a rotary valve 2, and a Venturi tube 3, and the blower 4 is connected to the dryer through a conveying pipeline 5 6. The outlet at the lower end of each cyclone separator 1 is connected to the delivery pipeline 5 through the rotary valve 2, or the outlet at the lower end of each cyclone separator is connected to the inlet end of the Venturi tube 3 on the delivery pipeline through the rotary valve, Or or the outlet at the lower end of each cyclone separator is connected to the delivery pipeline on the inlet side of the Venturi tube 3 on the delivery pipeline through a rotary valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com