A dynamic leaching residue sampling device

A sampling device and residue technology, applied in the field of chemical extraction experiments, can solve the problems of consuming a large amount of shower solution, cumbersome procedures, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

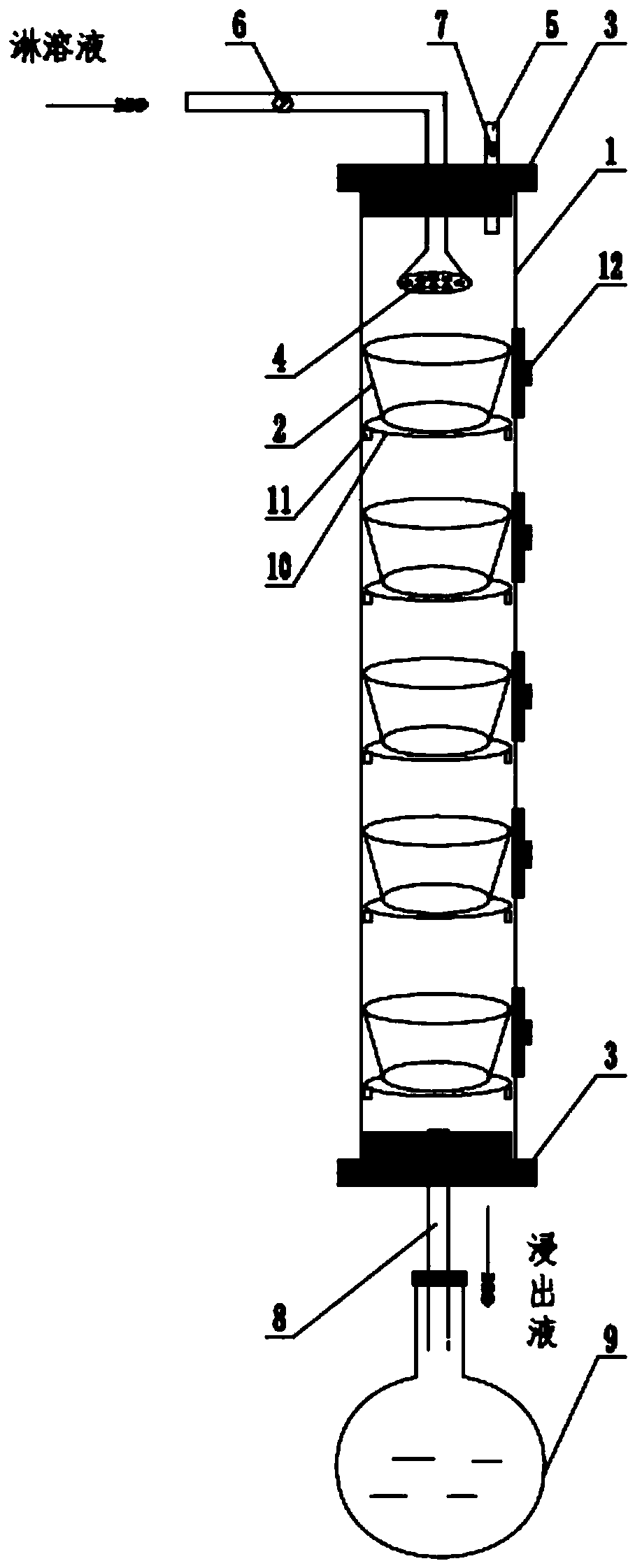

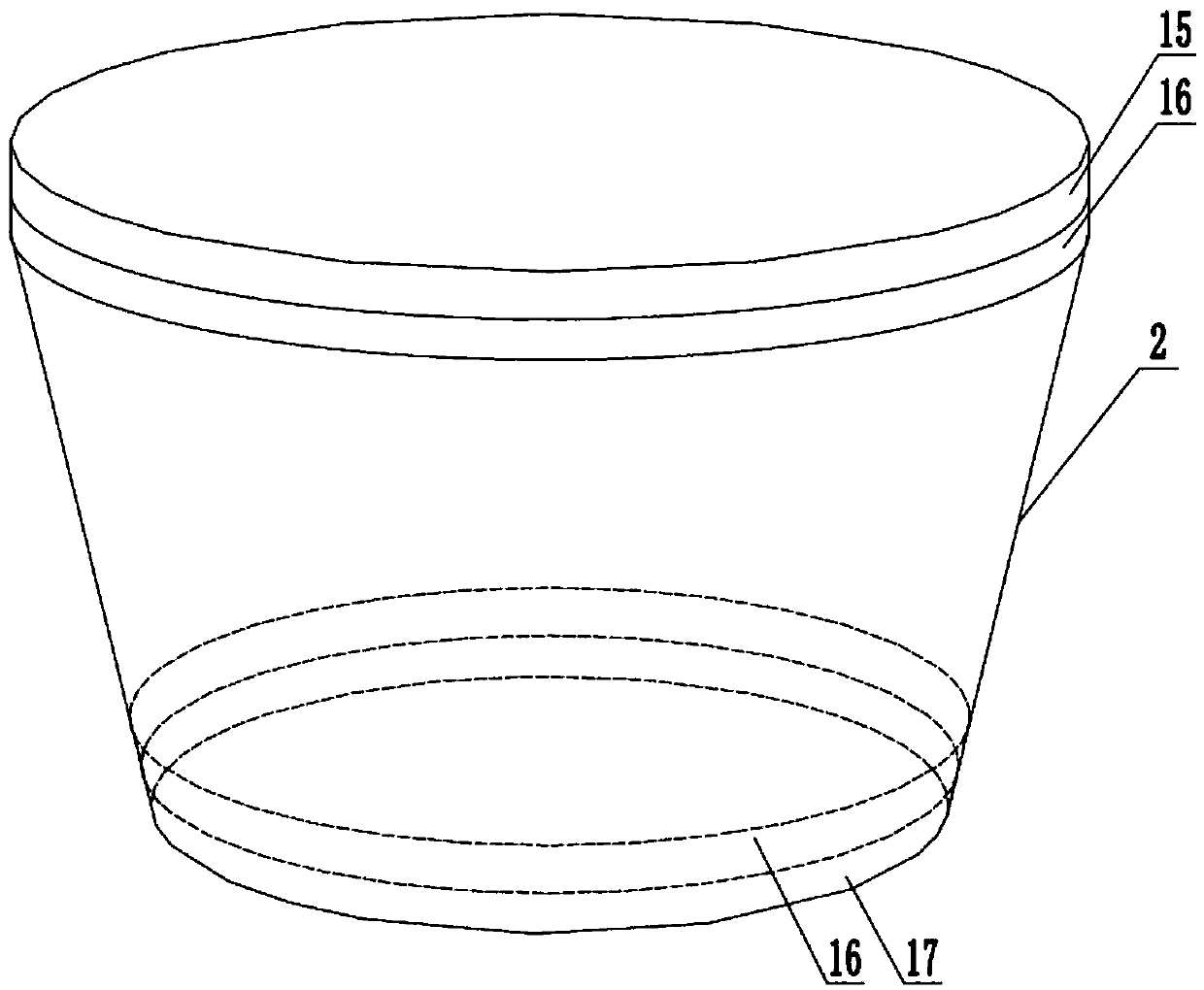

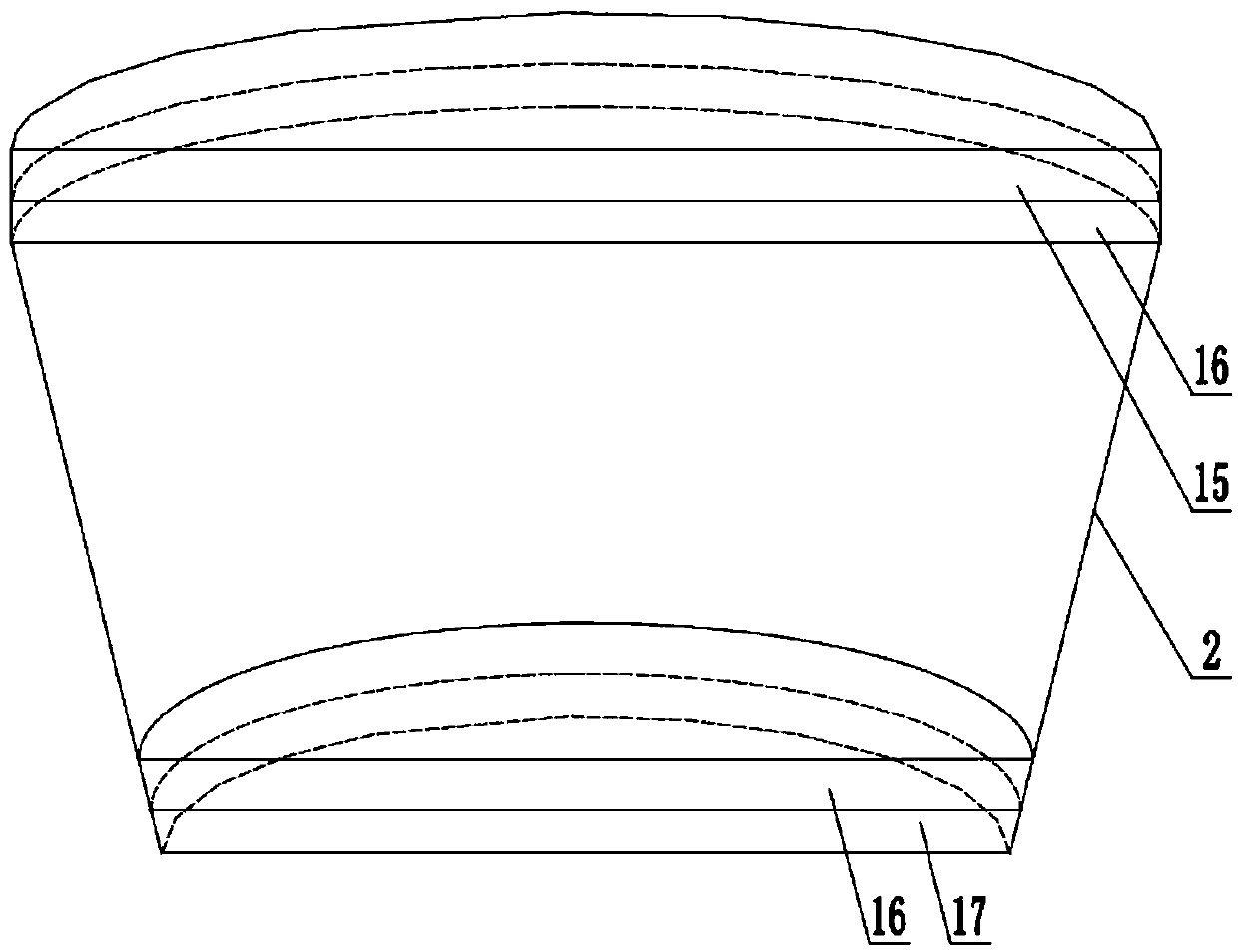

[0033] Such as figure 1 As shown, the dynamic leaching residue sampling device of the present invention includes a leaching column 1 and a sample holder 2 placed in the leaching column. The leaching column 1 is made of transparent plexiglass, which can observe the water-rock reaction process and progress in real time during the experiment. The sample holder 2 is made of polytetrafluoroethylene, which is in the shape of a cylindrical cone with a thick top and a thin bottom. The diameter of the upper end is slightly smaller than the inner diameter of the leaching column, and a diversion hole (not shown in the figure) is left at the bottom. PTFE has strong acid and alkali resistance, good stability, and is not easy to react with the leaching solution, and does not pollute the sample; the cylindrical cone-shaped design with a thick top and a thin bottom makes the leaching solution dripped into the surface sample in a planar shape During the infiltration process, it can fully cont...

Embodiment 2

[0043] 2.1 Selection of weathering index

[0044] Using chemical alteration index (CIA) and silicon aluminum ratio (SiO 2 / Al 2 o 3 ) and other two geochemical weathering indicators to judge the weathering characteristics of dynamic leaching residues.

[0045] (1) CIA

[0046] CIA is used to quantitatively evaluate the degree of weathering of feldspar silicate components, and its expression is:

[0047] CIA=[Al 2 o 3 / (Al 2 o 3 +CaO*+Na 2 O+K 2 O)]×100

[0048] In the formula, each oxide is the number of moles (mol); CaO* is the CaO in the silicate phase, and Ca needs to be deducted if the sample contains carbonate or phosphate. In practice, when CaO(mol)≥Na 2 At O(mol), CaO*=Na 2 O; when CaO(mol)2 When O (mol), CaO*=CaO.

[0049] During the chemical weathering process, with the decomposition of feldspar-like silicate minerals, base ions such as Ca, Na, and K gradually leached away, Al was enriched in the weathered residue, and the CIA value showed an increasing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com