Automatic continuous cooling and forming system for golden slab sugar

A technology of cooling molding and borneol sugar, which is applied in the fields of confectionery, confectionary industry, food science, etc. It can solve the problems of difficult standardized production, high labor intensity, and easy contamination of food, so as to reduce the risk of food contamination and labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

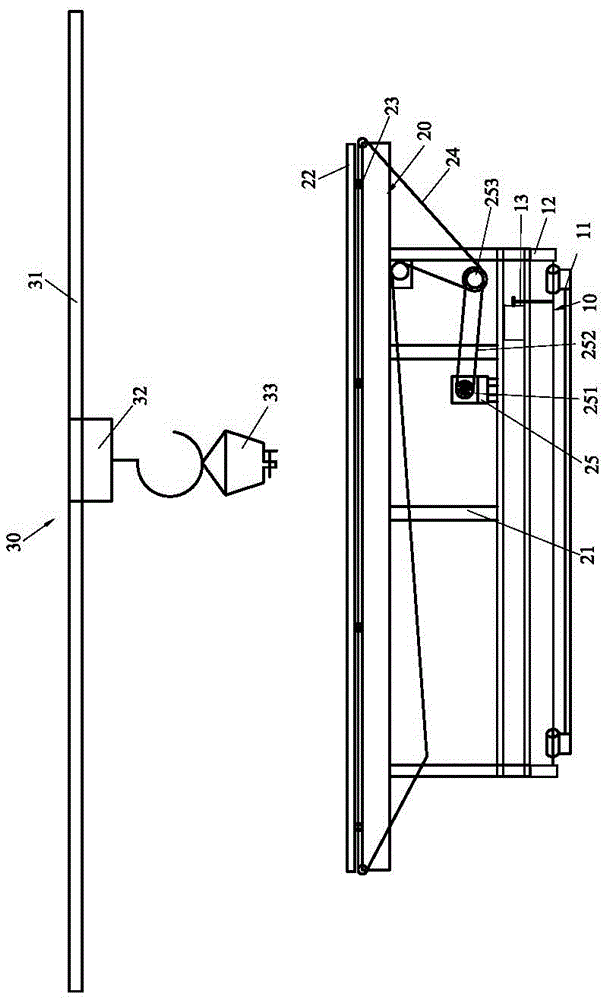

[0025] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a sugar bed car 10, a plurality of cooling sugar beds 20 and a power lifting transport device 30.

[0026] The sugar bed car 10 includes a guide rail 11 and a vehicle frame 12, the guide rail 11 extends longitudinally, the vehicle frame 12 is arranged on the guide rail 11 and moves back and forth along the guide rail 11, and the vehicle frame 12 is provided with a device to drive the vehicle frame 12 to and fro along the guide rail 11. Active drive device 13; in this embodiment, the drive device 13 is a motor drive device.

[0027] The plurality of cooling sugar beds 20 are arranged on the vehicle frame 12 and move back and forth with the vehicle frame 12. There is a detachable installation structure between the cooling sugar beds 20 and the sugar bed car 10, which can drive all the sugar beds by a single machine, and the equipment is simple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com