Treatment process combining absorption with infrared induction catalytic regeneration for indoor organic pollutants

A technology of organic pollutants and treatment process, which is applied in the field of various organic pollutants, adsorption and infrared-induced catalysis, and achieves the effect of high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

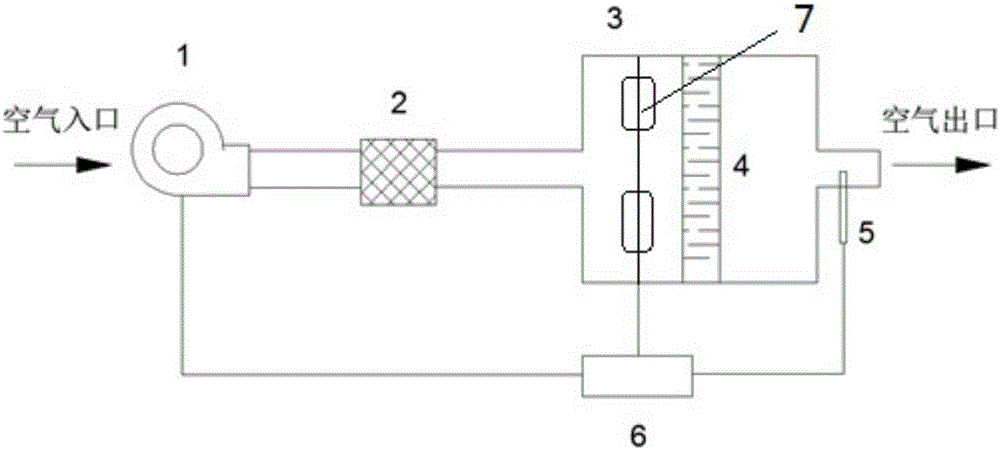

Image

Examples

Embodiment 1

[0066] Nanoporous adsorption catalyst material is δMnO 2 / activated carbon, the δMnO 2 Mix it with activated carbon according to the mass ratio of 0.2:1 and add it into deionized water, stir vigorously and mix evenly, and after suction filtration, dry at 50-100°C for 4-12 hours to obtain δMnO 2 / activated carbon. The infrared absorbing material used is Fe 3 o 4 , the mass ratio of the adsorption catalytic material to the infrared absorption material is 0.5, the organic pollutant is formaldehyde, the test space velocity is 50000 / h, and the imported formaldehyde concentration is 5mg / m 3 , the test results show that at room temperature (25°C) the time for the porous material to maintain a high adsorption performance is 80h. After the adsorption is saturated, it is irradiated with an infrared lamp and maintained for 1.2h, and the formaldehyde removal rate is stable above 98%.

Embodiment 2

[0068] The nanoporous adsorption catalyst material is nano-Pd particles / activated carbon. Mix the nano-Pd particles and activated carbon into deionized water according to the mass ratio of 0.1:1, stir vigorously and mix evenly, and dry at 50-100°C for 4-12 hours after suction filtration to obtain nano-Pd Granular / activated carbon. The infrared absorbing material used is nano-gold particles, the mass ratio of the adsorption catalytic material to the infrared absorbing material is 0.8, the organic pollutant is formaldehyde, the test space velocity is 100000 / h, and the imported formaldehyde concentration is 5mg / m 3, the test results show that at room temperature (25°C) the time for the porous material to maintain a high adsorption performance is 20 hours. After the adsorption is saturated, it is irradiated with an infrared lamp and maintained for 0.8 hours, and the formaldehyde removal rate is stable above 98%.

Embodiment 3

[0070] The nanoporous adsorption catalyst material is nanometer Pt particles / γAl 2 o 3 , the nano-Pt particles and γAl 2 o 3 According to the mass ratio of 0.2:1, mix and add to deionized water, stir vigorously to mix evenly, and after suction filtration, dry at 50-100°C for 4-12 hours to obtain nano-Pt particles / γAl 2 o 3 . , the infrared absorbing material used is nano-Rh particles, the mass ratio of the adsorption catalytic material to the infrared absorbing material is 1.5, the organic pollutant is formaldehyde, the test space velocity is 200000 / h, and the imported formaldehyde concentration is 5mg / m 3 , the test results show that at room temperature (25°C) the time for the porous material to maintain a high adsorption performance is 60 hours. After the adsorption is saturated, it is irradiated with an infrared lamp and maintained for 1 hour, and the formaldehyde removal rate is stable above 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com