Smashing device for medical consumables

A crushing device and technology of consumables, applied in waste disinfection or sterilization methods, magnetic separation, solid separation, etc., can solve the problems of lagging management of disposable medical consumables, avoid the spread of viruses or germs, and ensure easy maintenance , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

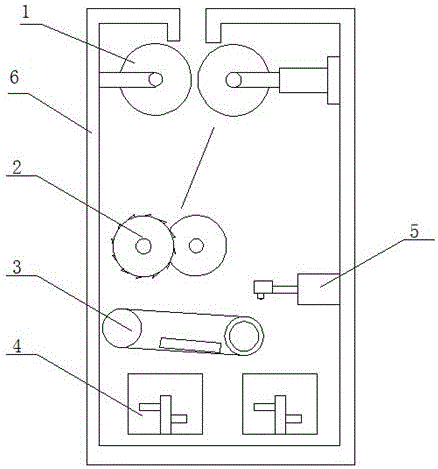

[0041] Such as figure 1 As shown, the present invention discloses a crushing device for medical consumables, a crushing device for medical consumables, which is characterized in that it includes a housing 6 with an inlet, and the inside of the housing 6 is divided into presses that are sequentially arranged to cooperate with each other. Flat area, crushing area, magnetic separation area, and collection area, and the flattening area corresponds to the entrance. A sterilization mechanism 5 is also arranged in the housing 6 . The design of the sterilization mechanism 5 can ensure the safe recycling of materials and realize the aseptic recycling of materials. The sterilizing mechanism 5 is an ultraviolet sterilizing mechanism 5 or / and a spraying mechanism, and the spraying mechanism is filled with disinfectant; the sterilizing range of the sterilizing mechanism 5 covers the space in the casing 6 or covers the collection area. The sterilizing structure equipment of this structure...

Embodiment 2

[0048] Such as figure 1 As shown, an intelligent crushing system for medical consumables of the present invention includes a flattening mechanism 1, a crushing mechanism 2, a magnetic separation mechanism 3, a collection mechanism 4, a controller, a weighing device, a sterilization mechanism 5, and a driving mechanism;

[0049] The flattening mechanism 1 comprises the main pressing roller, the auxiliary pressing roller and the scraping mechanism which cooperate with each other; the scraping mechanism is used to scrape the surface on the main pressing roller or the auxiliary pressing roller; A heating chamber is provided, and a heater is arranged in the heating chamber, and the heater is used for heating the main pressure roller; The auxiliary pinch wheel is tangent to the second auxiliary pinch wheel;

[0050] The crushing mechanism 2 includes a cutting wheel with a blade on the edge and a support wheel; the cross-section of the support wheel and the cutting wheel is in the s...

Embodiment 1

[0059] Based on Embodiment 1 or Embodiment 2, the sterilization mechanism 5 referred to in the present invention includes an ultraviolet lamp tube and a spray mechanism; the ultraviolet lamp tubes are arranged side by side in a horizontal direction, and the space in the housing 6 is respectively a weak ultraviolet light area from top to bottom , medium ultraviolet light area, strong ultraviolet light area; ultraviolet light intensity ratio, weak ultraviolet light area: medium ultraviolet light area: strong ultraviolet light area = 1:2:5, and the ultraviolet light intensity in the weak ultraviolet light area is not less than 12W / ㎡; area ratio, weak ultraviolet light area: medium ultraviolet light area: strong ultraviolet light area = 3:1:1; the spray mechanism is used to spray disinfectant, and the disinfectant is composed of the following materials by weight: 60 parts octanoic acid, 5 parts nonanoic acid, 30 parts alcohol, 6 parts iodine solution, 11 parts sodium hypochlorite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com