Surface shape correcting method for silicic acid yttrium-lutetium crystal

A technology of yttrium lutetium silicate and crystal, which is applied in the field of positron emission tomography to achieve the effect of meeting the precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Test conditions

[0046] Grinding equipment: ultra-precision active drive grinding machine

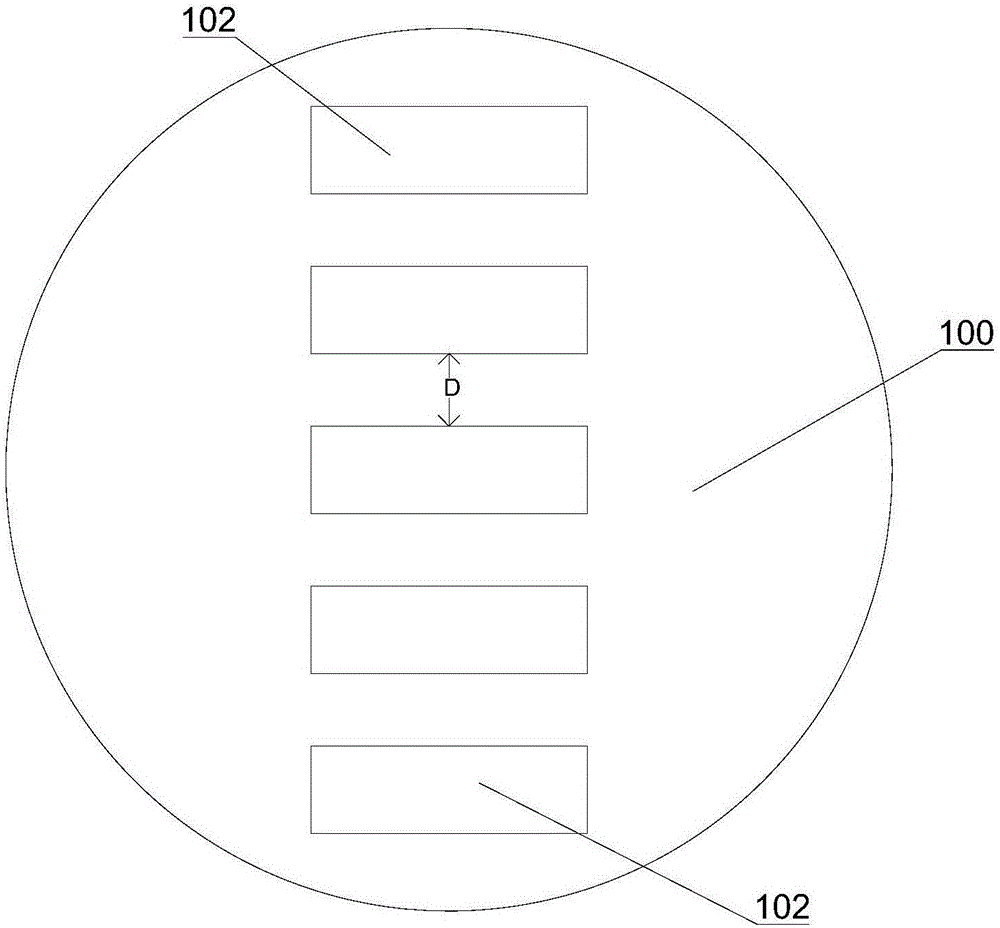

[0047] Grinding disc diameter: 300mm

[0048] Yttrium lutetium silicate crystal size: 4mm×4mm×20mm

[0049] Glass backplane size: diameter 50mm

[0050] Pressure: 2~4kPa

[0051] Grinding disc, polishing disc speed: 15 ~ 20rpm

[0052] Rotational speed of yttrium lutetium silicate crystal: 15~20rpm

[0053] 2. Testing equipment

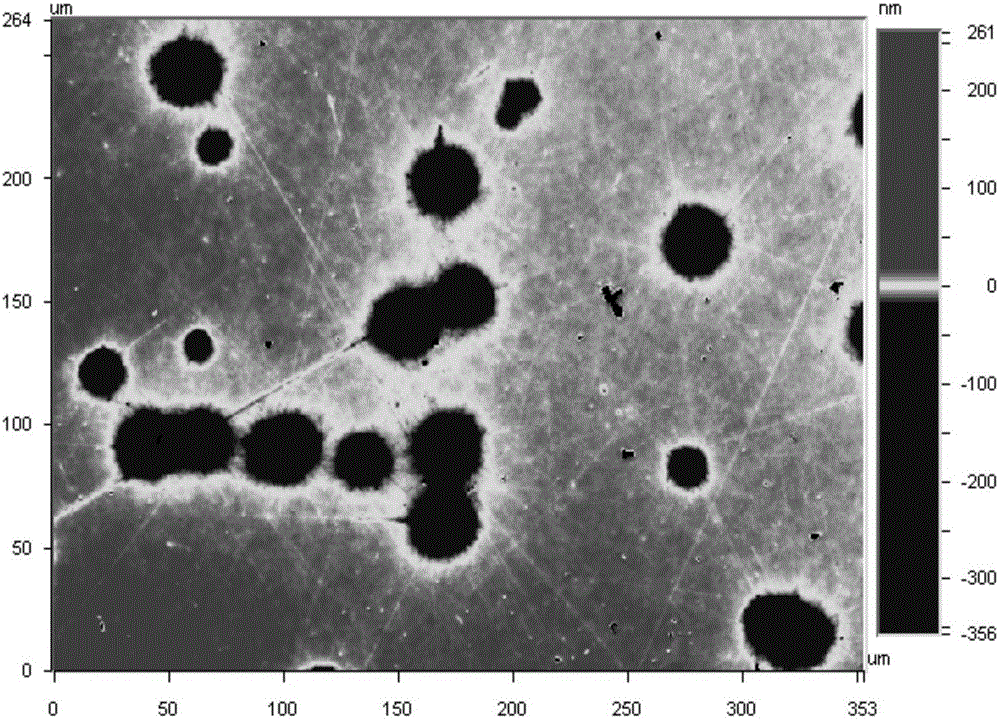

[0054] Roughness: Zygo optical roughness testing equipment

[0055] Surface shape: QED optical interferometer

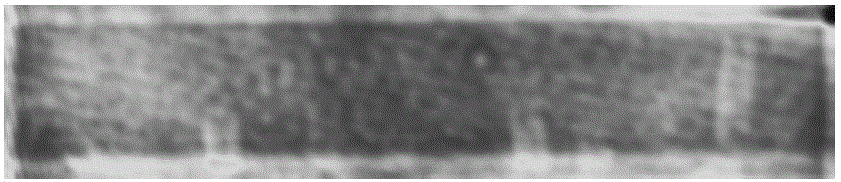

[0056] Appearance: Keyence optical digital microscope

[0057] Particle size: Malvern laser scattering particle size tester

[0058] Grinding method: The abrasive is continuously transported to the synthetic tin plate, so that the ground surface of the yttrium lutetium silicate crystal is in free contact with the synthetic tin plate, and the ground surface and the synthetic tin plate are in relative motion, and the abrasive is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com