High-load composite anaerobic reactor for treating high-suspension solid materials

An anaerobic reactor and solid material technology, which is applied in anaerobic digestion treatment and other directions, can solve the problems of high cost and large volume of anaerobic reactor, and achieve the effects of economical cost, high processing efficiency and land saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

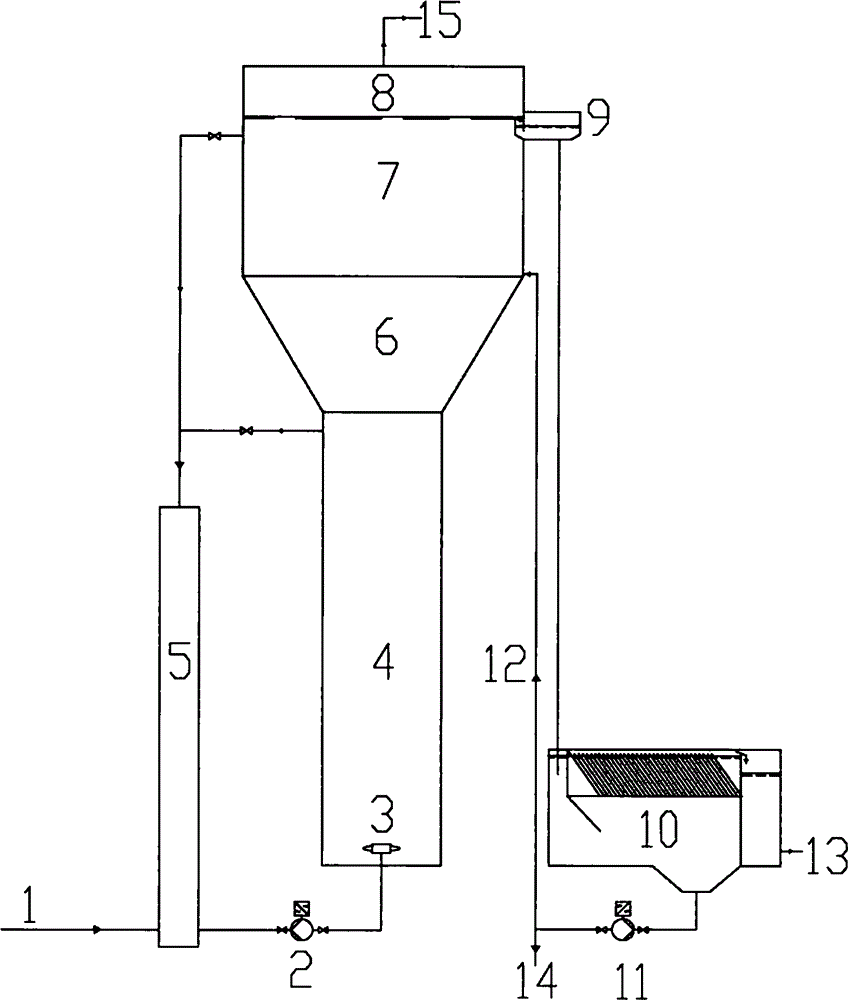

[0029] The following is a detailed description of the embodiments of the present invention. The description of the embodiments with reference to the accompanying drawings is exemplary and intended to explain the present invention, but not to limit the present invention.

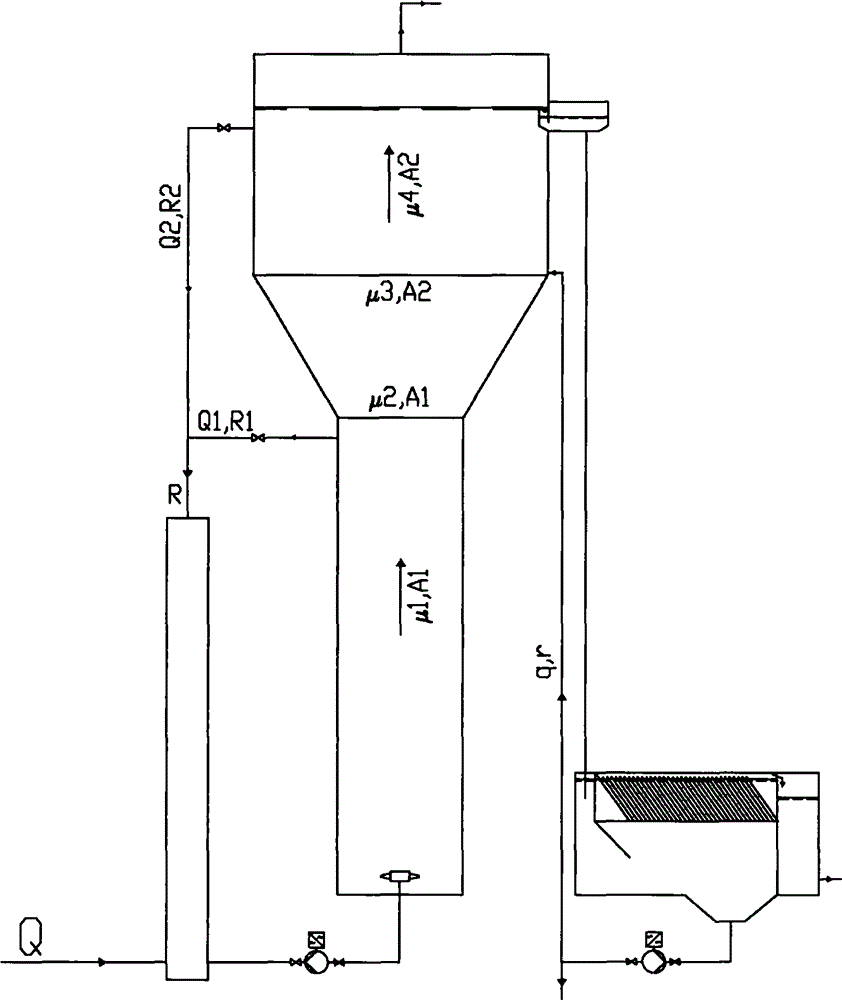

[0030] figure 1 It is a schematic diagram of the design parameters of the embodiment of the high-load composite anaerobic reactor according to the present invention, and it will be described in detail below.

[0031] In the schematic diagram, the rising velocity of liquid in the granular sludge bed area μ 1 =Q*(1+R) / A 1 , the recommended value is 1.0~10m / h;

[0032] The rising velocity of the liquid in the lower section of the buffer zone μ 2 =Q*(1+R 2 ) / A 1 ;

[0033] The rising velocity of the liquid in the upper section of the buffer zone μ 3 =Q*(1+R 2 ) / A 2 ;

[0034] The rising velocity of the liquid in the flocculent sludge bed area μ 4 =Q*(1+R 2 +r) / A 2 , the recommended value is 0.3~1.0m / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com