Axial chiral biphenyl derivative having 3D effects with naked eyes after film formation, as well as preparation and application of axial chiral biphenyl derivative

An axial chirality and derivative technology, applied in the field of axial chiral biphenyl derivatives, can solve the problems of poor three-dimensional effect, time-consuming, and inconvenient viewing by users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

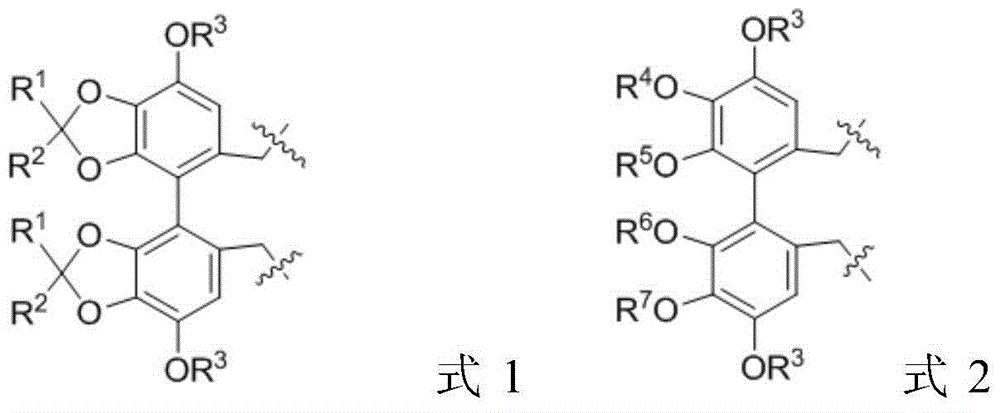

[0032] Formula 3 (R 1 =R 2 = H, R 3 =CH 3 , R 8 = OTs, OMs, OTf, OTMS, X (X = halogen)) 1 equivalent of biphenyl compound, 2 equivalents of bromine, mixed and dissolved in 10 times the weight of DMF, adding 2 equivalents of triethylamine as an acid-binding agent , heated to 80°C and reacted for 5 hours. After the reaction, the reaction liquid was gradually dropped into water, and the precipitated solid was filtered and dried to obtain the blue reactive dye (Formula 7).

Embodiment 2

[0034] Formula 5 (R 3 =R 4 =R 5 =R 6 =R 7 =CH 3 , R 8 = OTs, OMs, OTf, OTMS, 1 equivalent of biphenyl compound shown in X (X=halogen)), 2 equivalents of reactive brilliant blue, mixed and dissolved in 10 times the weight of DMSO, adding 2 equivalents of potassium carbonate as an acid-binding agent, Heat to 90°C and react for 4 hours. After the reaction, gradually drop the reaction solution into water, and filter and dry the precipitated solid to obtain the reactive brilliant blue axis chiral biphenyl derivative dye.

Embodiment 3

[0036] Formula 3 (R 1 =R 2 = H, R 3 =CH 3 , R 8 =NH 2 ) 1 equivalent of biphenyl compound shown in ), 2 equivalents of reactive brilliant red (K-3B), mixed and dissolved in 10 times the weight of DMSO, added 2 equivalents of potassium hydroxide as an acid-binding agent, heated to 80 ° C for 5 hours, and the reaction After completion, the reaction solution was gradually dropped into water, and the precipitated solid was filtered and dried to obtain the reactive brilliant red axial chiral biphenyl derivative dye (Formula 8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com